Victor Manufacturing Set for Record Growth Following Appointment

One of the UK’s leading food service and retail equipment suppliers, Victor Manufacturing, has today announced new ownership following a management buyout by long-standing managing director, Phil Williams, which enhanced record growth. Phil, who is the current managing director of Victor Manufacturing and has been with the company for almost 20 years, took the decision to take over the business when the Mrs J M Mountain Will Trust opted to sell the manufacturing firm. Victor Manufacturing has seen rapid growth over the last five years with turnover increasing from £5 million to £9 million. Following the takeover, Phil has ambitious growth plans to continue this success with a clear strategic goal over the next five years aimed at growing annual revenues to £20 million. Phil Williams, managing director of Victor Manufacturing, said: “It is a really exciting time for Victor as we enter new markets and continue to grow our existing ones. Having been part of the company for almost 20 years, I am looking forward to working with the team to continue the great work we have become renowned for over the last 75 years. “The new ownership will provide peace of mind to our staff, customers and suppliers that it is business as usual and with my new commitment as owner as well as managing director, they can be confident in a very strong future ahead.” Significant new accounts over the last 12 months, along with being appointed the exclusive UK partner of leading US manufacturer, Duke, has had a positive impact on the company’s continued year on year growth. This, combined with opportunities in the retail sector, will aid the manufacturer to achieve its ambitious growth plans over the next five years. Celebrating its 75th anniversary in October 2019, Victor Manufacturing specialises in the manufacture and supply of food service equipment to some of the UK’s largest companies and groups in a variety of sectors including education, care, public sector, hospitality, contract catering and retail. The firm employs 120 staff over three facilities in Bradford. The deal was advised by the corporate finance team at Yorkshire accountants and business advisers, Garbutt + Elliott, led by partner, Richard Feltham; legal advice was provided by corporate partner Paul Johnson from the Leeds office of national law firm, Mills & Reeve; and financial funding was secured from HSBC UK to support the management buyout. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Sofitec Expands Its Capabilities in Complex Sheet Metal

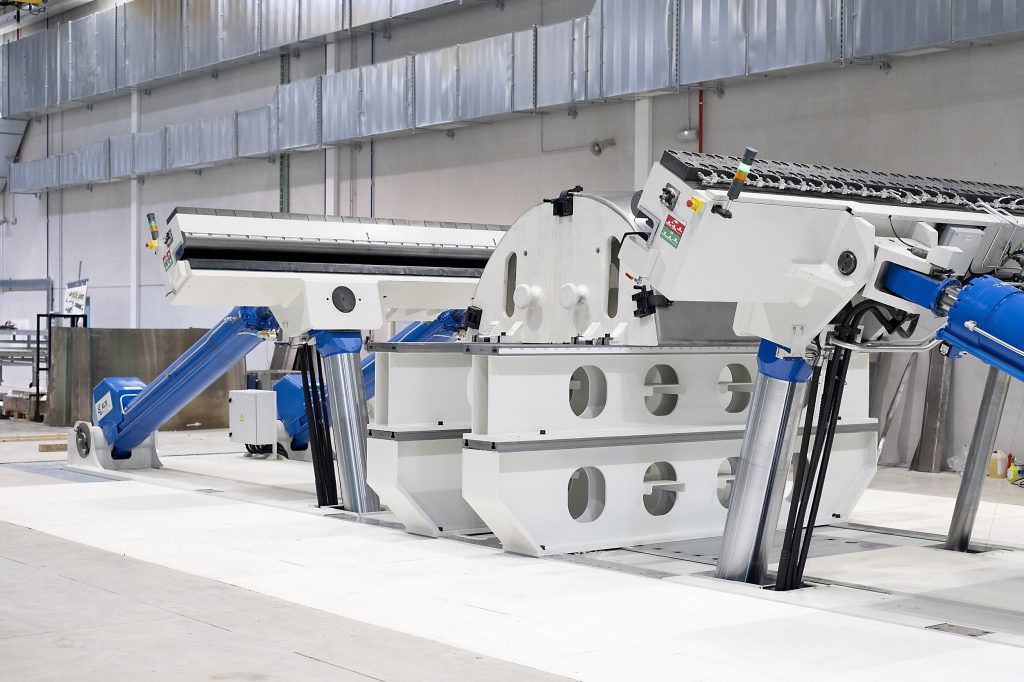

Sofitec, a company specialized in aerostructures manufacturing and assembly, is accomplishing the launch of a new area of complex sheet metal processes for the aeronautical industry. With an investment of 20 million euros, the company began last year the expansion of its facilities, as part of which it has recently acquired two new equipment that will increase its technological capabilities and diversify its products and processes catalogue. Concretely, Sofitec has incorporated into its technological fleet a stretch forming machine specially indicated for cold plastic deformation processes. This type of metalworking improves the properties of the treated material by exceeding its inherent elastic limit, making the final shape of the piece stronger (after even machining operations) and reducing the possibility of defects in its interior curvature. Also, the new equipment will allow the application of simple, complex curvatures and non-uniform geometries, thanks to its stretching force of up to 600 tons. The company has also acquired, as part of this technological expansion, a 5-axis trimming machine of high performance and precision, with which it improves its capacity for the machining of large dimension elements, thanks to its mobile bridge system and aerial guidance. It is expected that the new facilities under construction, annexed to the current ones, will be fully operational in the last quarter of 2019. With an area of 11,600 sqm -which will be added to the existing 38,000- will allow the company to increase its available capacity by 80%, in addition to raise its turnover. Along with the mentioned areas, the expansion also includes the launch of an automatic baths line for anodizing of metallic materials, cleaning, and penetrant dye inspection; and a robotic painting line. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

WCM and IIOT: Achieving world class standards

WCM and IIOT: Achieving world class standards : Whilst ‘zero waste’ and ‘zero loss’ are aspirational targets for manufacturers large and small, some leading UK manufacturers are now reporting achieving these impressive standards using World Class Manufacturing (WCM) methodologies. Traditionally a manual approach, WCM requires buy-in from key decision makers and the persons responsible for the manufacturing process. This can mean significant investment and can prove very resource intensive, which is likely the reason why WCM is not more widely adopted. However, some pioneering plants are now utilising the latest advances in technology to support the WCM methodology with specially designed software. John Roberts, operations director of Idhammar Systems explains how – with the right commitment from the organisation, and the right software to expedite processes and support improvements – every manufacturer can strive for world class manufacturing standards. Why WCM? Leading UK businesses across a range of industries are already working to embed WCM initiatives, including Unilever, Rolls Royce and Jaguar Land Rover and it’s predicted that many more will soon follow suit to achieve their increasingly ambitious targets. Devised by Professor Yamashina in Japan in 2005, WCM has its foundation in TPM (Total Productive Maintenance). It works to achieve zero loss with zero defects, a concept that’s becoming increasingly more important as more organisations turn to focus on the environmental impact of their production. Ultimately, it’s a set of concepts, policies, techniques, and principles for operating and managing a manufacturing company. There are 10 key technical pillars of WCM including: safety, the environment, cost deployment, focused improvement, autonomous maintenance and workplace organization, professional maintenance, quality control, logistics and customer service, early equipment management; and people deployment. All require individual consideration in order to be truly effective and all require the attention of the entire organisation. In order to address all 10 technical pillars, it’s now considered necessary to use software; but this is a controversial subject. Here’s why… How does the IIOT complicate things? The IIOT, set to become a $225 billion market by 2020, didn’t exist in 2005 when the theory of WCM first originated. After all, today’s processing power was not available over a decade ago – instead, the data available from machines, systems and devices was usually gathered, processed, distributed and analysed by people (not computers). However, even in the smallest manufacturing sites today with increasingly connected machinery, systems and devices, this level of analysis is simply not possible at a low cost without smart technology. This is why organisations such as Idhammar Systems are playing a pivotal role in developing IT solutions dedicated to allowing manufacturers to work towards their zero-defect targets faster and more efficiently than they could without such systems. Introducing Smart Technology Although WCM is heavily reliant on personal engagement, there are fundamental building blocks to which technology proves crucial. For example, as well as improving efficiencies, with robots able to perform the work of three to five people depending on the task, introducing smart technology can help to free up time and resources within your team. By automating data acquisition, analysis and reporting processes, technology can allow your skilled people to engage in more complex, technical tasks. Additionally, this resource can prove pivotal when it comes to acting on the data that the systems provide – particularly if the insights are served up in an easily digestible format. As well as gathering vital information, digital systems like Idhammar’s can also help to decide what to do with the data, routing it to the right people whilst displaying it in an acceptable manner. In turn, creating a measurable operational process. The smartest technology also helps to make this process even more streamlined, utilising resources such as voice technology for time saving and increased accessibility. For example, manufacturers are able to recruit the help of Siri, Alexa or Google, telling them what’s happened, and a remedial course of action can be initiated on the factory floor almost immediately – particularly useful when dealing with any Emergency Work Orders. Additionally, with increased data being input into the systems, algorithms are becoming more intelligent, with many systems utilising AI technology to update their algorithms based on historic outcomes and learnings. Many organisations are also looking at AR so that technicians will not only be able to see the equipment they’re working on through HoloLens, but they’ll also be able to call up essential maintenance instructions and safety advice when needed the most. Is this all possible now? This technology may seem quite futuristic, but the short answer is yes, this is certainly achievable now. However, for WCM standards to be truly achieved, this smart approach requires sustained engagement from senior level management. The deployment of a wide range of new IT systems may be deemed necessary to make it possible, and it may also require a cultural shift to change attitudes of production directors, technicians and all those engaged in the production process. Technology is evolving at an incredible pace and is becoming more intelligent as each year passes. Yet despite advances in digital capabilities, without the backing of senior leadership, WCM standards cannot be achieved. After all, the benefits available from the introduction of WCM will not be obtained solely by developing technology. It is not a software project nor is it a technology project. Committing to WCM is usually the catalyst for major cultural change within the organisation and therefore requires cooperation from members of the team. If this can be achieved, your organisation is set to reap the benefits with improved efficiencies, reduced waste and a fast return on investment in any technology that supports the methodology. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Leicester Technology Centre to Boost Flow Control Engineering

Leicester Technology Centre to Boost Flow Control Engineering : ERIKS UK has opened a new facility within its Flow Control Technology Centre in Leicester, which brings together specialist knowledge and components in all aspects of industrial flow control systems under one roof. The centre employs 34 people, and comprises of a workshop for repairing, designing, and upgrading pumps and valves, as well as an ‘Automation Cell’ where ERIKS develops and builds complete flow control solutions. The facility is staffed by engineers from a wide range of disciplines who collaborate to deliver turnkey flow control solutions such as in-line blending and formulating, automatic dosing, dilution, filling, batching, filtration and clean-in-place systems. By basing the team at the Leicester site, every stage of the design and production process can be carried out in one place. This includes the assembly of bare shaft pumps, testing and certification of valves and actuators, and mounting whole solutions onto skids ready to integrate with whatever direct control system the end user operates. “Developing specialist flow control and dosing systems demands specialist knowledge, a comprehensive understanding of a wide range of components and access to these parts at competitive prices. By bringing all the expertise and production capabilities together, we can deliver tailored solutions that help customers reduce production downtime, improve health and safety, and increase the reliability of their processes and assets,” said Andy Silver, ERIKS’ Flow Control Director. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

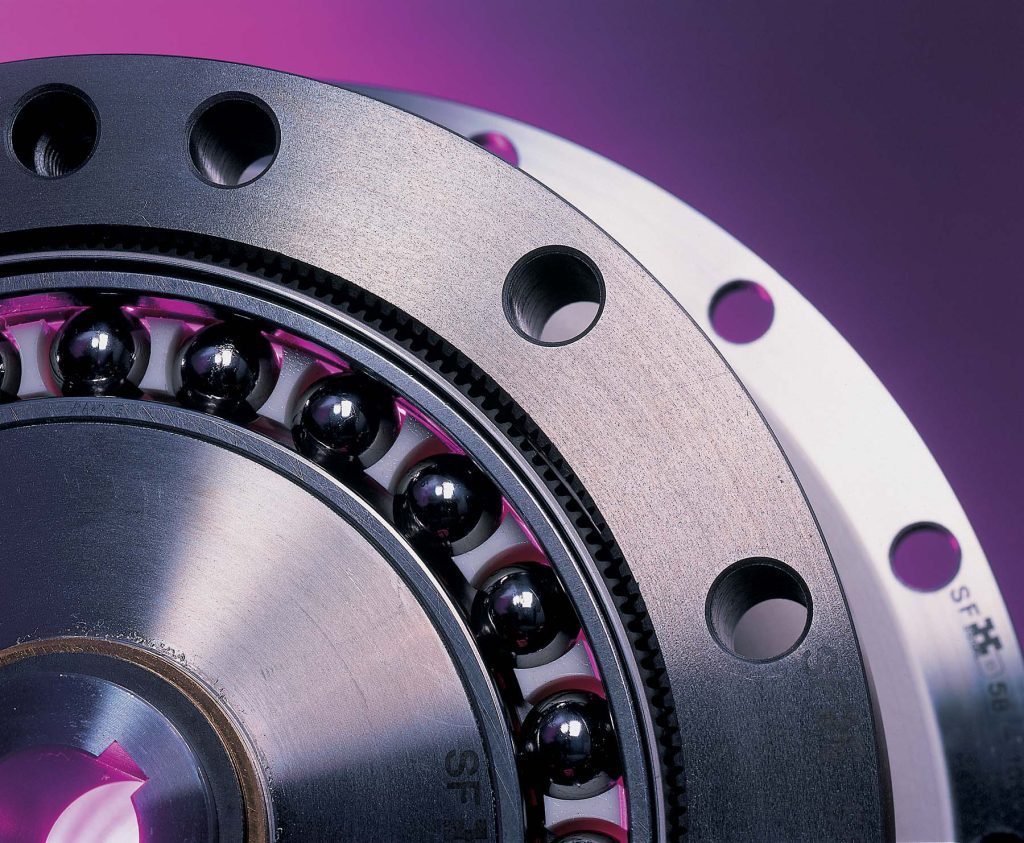

Harmonic Drive AG Celebrates Manufacturing Its Millionth Gear

20 years since the company started gear production in Limburg, specialist gearing company Harmonic Drive AG has announced that the company has manufactured its one millionth gear. The milestone can be attributed to the growing need for precision in applications, following the increased adoption of industrial automation in recent years. Automation is advancing quickly and to keep pace, design and mechanical engineers are striving for new ways to develop and enhance the performance of their applications. To achieve this, engineers are turning to leading manufacturer Harmonic Drive to integrate its high precision gear offering and meet the demands of today’s highly technological world. “Celebrating the manufacture of our millionth gear is a real testament to the wide product offering we now have available and the increased customer demand we have received for our specialist gears,” said Graham Mackrell, managing director of Harmonic Drive UK. “In fact, we plan on extending our portfolio in the mechatronic area and working on projects to decentralise control technology in smart drives, which we will see a higher need for in the coming years. “Having served our customers for many years now, we understand that it’s as important that our product lines are adaptable as it is that they are efficient, precise and effective. We have been able to evolve alongside the industry to ensure our customers can remain competitive in changing markets. In fact, it was in 2014, our series production of cross roller bearings began, and it was then we were able to respond more strongly to our customer’s needs. “Designed with a high degree of rigidity, high running accuracy and torque capacity, the bearings are ideal for use in robots, machine tools and medical devices. Our expertise allows us to create roller bearings designed for specific customer needs and this is how we’ve been able to position Harmonic Drive as a single source solution provider, which we will continue to do as we develop the next generation of solutions.” Harmonic Drive has transitioned in line with market changes to become a system provider for a wide range of sectors, ranging from oil and gas to medical devices, rather than just a component supplier. In addition to keeping up with market demands, the company is renowned for its investment in research and development projects, such as the creation of specialist test equipment and machines to meet complex procurement frameworks. The Limburg site celebrating the manufacturing milestone was responsible for the development of the company’s high-power density and smooth operating servo actuator range. This specialist actuator is commonly used to achieve precise linear and rotary motion control in industrial machine tooling, robotics and aerospace applications.

Inspiring the Female Future with Advanced Engineering 2019

On 23 June 1919, a committee of influential women sensed a new dawn. The First World War had ended, and significant steps had been taken towards women’s suffrage. The group, ranging from designers and munitions factory managers to wives of eminent engineers, rallied to found the Women’s Engineering Society (WES). 100 years later, progress for women in industry has often felt stagnant. Hetal Patel, Marketing Projects Manager for the UK’s largest annual manufacturing and engineering exhibition, Advanced Engineering, discusses the importance of women in engineering. As we celebrate the centenary of the Women’s Engineering Society, the fact that only eleven per cent of the UK’s engineers are female is a tough pill to swallow. The Society’s initial journal outlined its aims to “encourage and stimulate all women who are interested in engineering”, but today’s figures show that it’s often hard to see these efforts come to fruition. So, what can be done to nurture talent in this milestone year? The state of industry The UK has the lowest percentage of female engineers in Europe. As it stands, this figure isn’t set to rise any time soon. It’s estimated that less than eight per cent of engineering and manufacturing apprentices are female, with figures plunging to as low as two per cent in the building and construction sector. But the UK needs to significantly increase its number of engineers. The STEM skills shortage is costing businesses £1.5 billion in recruitment every year. For the engineering sector to reduce its skills shortage, it needs to employ around 186,000 recruits each year until 2024. Role models To inspire the future, we should reflect on the past. A lack of role models is often cited as a reason why women shy away from a career in this industry. However, the reality is that our engineering heroines are often unsung. The pressures of war drew many women to the home front, only for them to experience rebuke once men returned. In resistance, the founders of WES created a committee that promotes engineering as a rewarding profession for women as well as men. The original members of the group paved the way for women in industry. Renowned for her adventures as a pilot, Amy Johnson was a qualified engineer and WES president from 1933-34. Johnson’s campaigning inspired others such as Dorothy Spicer, another society member and the first person to hold all four types of aeronautic licenses. Whether it’s a female Doctor at the helm of the Tardis, or a woman encouraging the next generation of engineers, prominent role models need to be realised as figures of inspiration. Striking the balance If we are to progress, we must strive for a more balanced workforce that reflects the diversity of our society and invests in the development of all talented workers. McKinsey’s Delivering Through Diversity report states that many companies struggle to increase the representation of diverse talent and create truly inclusive organisational cultures to profit from diversity. Yet data from 2017 found that companies in the top-quartile for gender diversity on their executive teams were 21 per cent more likely to have above-average profitability than companies in the fourth quartile. To address the skills gap and boost productivity, companies need to act to diversify. The next generation International Women in Engineering day takes place on June 23. To encourage women to pursue a career in engineering, action has to begin as early as possible. Professor Karen Holford, Deputy Vice Chancellor at Cardiff University and voted one of WES’s most influential female engineers in 2016 explains that “the stumbling blocks are there from a very young age, such as girls not being given toy trains and cars to play with. It may sound like a small thing, but unconscious stereotyping is still holding girls back, without them even realising it. “Schools must ensure that teachers have the critical skills to teach the subjects needed for a career in engineering. Finally, companies need to do more to promote flexible working for both men and women. This way we can ensure that the burden of childcare is equally shared so that women aren’t out of the workplace for long periods. If we can solve these problems, I believe we’ll see a big increase in women choosing engineering careers and, even better, staying in them.” The Women’s Engineering Society will be exhibiting at Advanced Engineering from 30–31 October 2019 at the National Exhibition Centre, Birmingham. For more details on the show’s exhibitors, or to sign up to attend, please visit: www.advancedengineeringuk.com

Small Businesses Confidence Hits Two-Year Low

Small Businesses Confidence Hits Two-Year Low : The proportion of small businesses predicting growth for the next three-months has fallen to 34% – its lowest level for eight successive quarters and, for the first time, the proportion of businesses predicting significant expansion has fallen below 5%. The new research from Hitachi Capital Business Finance asked a nationally representative sample of 1,184 small business owners to forecast their growth outlook for the three-month period to 30 June. Whilst the percentage of small businesses predicting growth held firm at 36% over the previous three quarters – through a period of extreme political and economic uncertainty – this month sees the first fall in the number of small businesses predicting any form of growth – whether significant expansion or modest, organic growth. This time last year, the spring months saw an annual high in business confidence, as businesses started the new tax year with bullish plans for the year ahead. This spring, confidence is sliding. Asked what the barriers to growth where, market uncertainty (31%), unwillingness to embrace risk (17%) volatile cash flow (13%) and the cost of labour (12%) were all key factors. Further, when asked which initiatives small business owners were taking in order to secure future growth, key initiatives mentioned included: keeping fixed costs down (41%), improving cash flow (22%), tackling late payment (28%), expanding into overseas markets (16%) and investing in new equipment (12%). On the upside, the north emerged as the country’s engine room for growth, with small businesses in the North West (43%) and the North East (41%) most likely to predict growth – compared to the national average of 34%. In contrast, small businesses in the west were the least confident: Welsh businesses were least confident about the future, closely followed by the South West – 23% and 28% respectively. In only three regions had the growth outlook of small businesses improved since the start of the year. By sector, quite a lot of movement was noted since the start of the year. Despite a January of bleak trading announcements from the high street, the latest Hitachi Capital data reveals a sharp improvement in growth outlook from the retail sector among small businesses (up 9% on Q1 to 40%), with confidence in Real Estate rising by 17% since January. Conversely growth forecasts have fallen most sharply in the Finance/Accounting and Transport/Distribution sectors (falling 9% and 17% respectively). Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

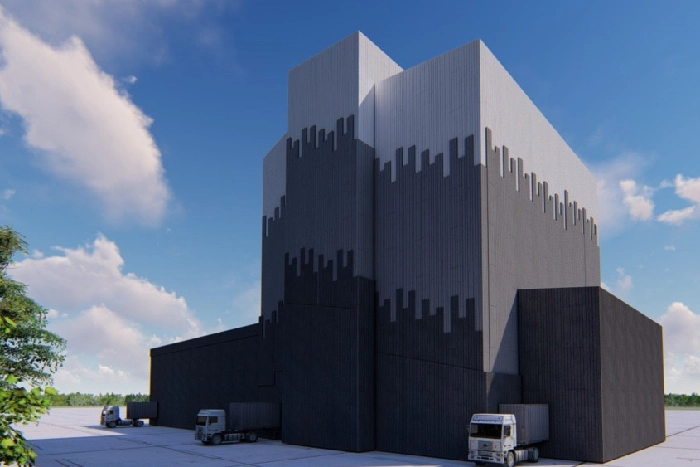

I’Anson Brothers Invests in New Production Facility

I’Anson Brothers Invests in New Production Facility : Plans to build a 23,000 sq ft production facility have been unveiled by animal feed manufacturer I’Anson Brothers, who is making the biggest single investment in the company’s history. The £12 million plant will be built at Dalton New Bridge, the next phase of the Dalton Industrial Estate. Producing an initial 150,000 tonne capacity per year – with two production lines producing over 30 tonnes per hour – this increased production will enable I’Anson to meet the growing demand of existing customers, expand its export operations and continue to be a major supporter of the North Yorkshire farming and wider economy. “This is an exciting time for I’Anson, and everyone connected to us. For the last 60 years we have been based at our Masham mill and have continually invested in new technology to increase production volumes and our efficiency. However, the physical limitations of the site mean we have reached production capacity, constraining our ability to grow,” said Chris I’Anson, chairman and managing director of I’Anson Brothers. “We are investing in the future of our business and this new facility paves the way for us to not only meet the increasing demands of our existing customers, but also provides significant opportunities for future growth and allows us to continue being a proud supporter of the local economy,” he added. I’Anson currently employs 80 people from the local community and the facility will initially create a further 10 jobs. It will also allow I’Anson to grow its existing network of local producers, farmers and suppliers from whom it buys a large proportion of its raw materials for manufacture. Founded in Masham in 1900, I’Anson has grown to become a leader in the production of animal feeds and has been based at its current mill for the past 60 years. It supports over 3,000 customers locally across the North, nationally and internationally, exporting to over 40 countries worldwide. The business’s headquarters will remain in Masham, where it will continue to manufacture an extensive range of micronized feeds, specialty rations and horse feeds. The new facility will focus on the production of bulk farm feeds, with the capacity created in Masham enabling the business to expand its UK and overseas sales of its British Horse Feeds and The Golden Paste supplement range, as well as continue to lead new product development. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Protect Your Labelling System

Protect Your Labelling System : Ever woken up in the night in a cold sweat. Your worst nightmare is playing out. Your label printer has stopped working, your products can’t be shipped and your factory grinds to a halt. No – I can’t imagine you’re kept awake at night thinking about labels – but perhaps you should. Whilst the chances are relatively small – I’ll bet you’re like most UK manufacturers, you’ve not given this insignificant but critical part of your production process a second thought. Labelling is one of those low profile but critical points in an organization. Not being able to put labels onto your products means that your customers can’t accept your products and your goods can’t be shipped. https://expertlabels.co.uk/labelling-assessment If you’re worried about bringing your operation to a grinding halt because of your labelling or you might be missing out on the benefits of thermal label printing – here are five things you can do to reduce the risks to your organisation: Spare Printers Having just one printer opens you up to risk. It breaks and you stop printing labels. Eliminate that risk with a spare printer. The good thing about spare printers is that they’re not redundant. Having more than one printer means you can share the workload across your printer fleet – reducing wear and tear at one single point. As long as you can print labels with another printer if primary printer gets dropped and damaged, you eliminate that risk. Single Manufacturer Printer Fleet Having one make of printer means interchangeable ribbons, labels, printer language and parts. Spare printheads can be used by any one of your printers so you only need one spare. Maintaining label and ribbons stocks are more simple. Printers can be redeployed without needing to change printer drivers and software. Your operators and support team know how to operate and maintain them and don’t need to spend time learning the quirks of each type of printer. Networked PCs for up to the second status reports For a modest increase in cost, you can network your printers. Most industrial class printers come networked as standard. Having a printer visible on your network means the printer fleet can be managed more effectively. Plus, of course, you can to print from any computer on the network. Back ups of Label design software and templates With larger organizations, an IT manager’s neck is on the line if backing up is not done. However, with some smaller businesses, back ups, especially on a standalone label printing computer, are not always in place. This is a schoolboy error but could stop printing. Automated Data Entry An almost invisible error is where a label looks right but the barcode contains the wrong data. It might be something like the wrong use-by date or product serial number. Industrial grade labelling software like Seagull Scientific’s BarTender enables you to automate data entry. Date codes can be calculated and included in printed labels. Product serial numbers can be taken directly from your database or scanned from an existing barcode. To make sure though, a quality control process that checks labels should be in place to spot data entry errors. But there’s more We’ve got 25 other ideas to either reduce your labelling risks or improve the efficiency of your labelling system. Visit us here to assess your label printing risks. Summary There’s lots of reasons why your labelling system can break down. Whilst they’re uncommon, the consequences of labelling failure can be catastrophic. Thermal label printing is a complicated, specialist area of expertise that can be made much more efficient, effective and reliable by working with thermal labelling experts. Servicing thermal label printers is different from standard office printer servicing. Roll labels are made in a different way to sheet paper and buying them is different. With the likelihood that you’re using different materials such as plastics and thermal coated papers – purchasing labels is more complicated than paper. Thermal ribbons are different from toner-based or liquid inks. The capability of a thermal transfer printer is significantly different to that of a flat sheet inkjet or toner-based printer. All these factors can mean a much more efficient process or a chaotic and inefficient labelling solution. Protect Your Labelling System Today For a no commitment chat to see if you could be getting better results from your labelling or help identifying potential danger points, give Miles a call at Expert Labels Limited, click the chat button in the right bottom corner or email info@expertlabels.co.uk and ask for Miles. https://expertlabels.co.uk/labelling-assessment Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Planning Application Submitted for Warehouse Extension

A planning application has been submitted by real estate investors M&G Real Estate (M&G) to extend and remodel its distribution warehouse in Redditch that is let to Pilkington Automotive, part of the NSG Group. “Offering NSG Group the opportunity to grow their premises in Redditch is a great example of our proactive asset management approach being realised, particularly given the existing building was designed with flexibility for future expansion,” said Chris Jeffs, director, investment management at M&G Real Estate. The planning application follows an agreement with NSG Group to relocate its automotive manufacturing operations from Kings Norton, amalgamating its manufacturing and distribution operations within a single 320,000 sq ft unit in Redditch. Work on the development is still subject to planning consent, but if approved it will start later this year to allow for NSG Group to take full occupation in Summer 2020. NSG Group’s existing Redditch distribution business will remain operational throughout and a new 20-year lease has been agreed on the extended premises. The proposed development will provide a scheme that meets NSG Group’s current and future needs ‘as a modern, high quality combined manufacturing and distribution facility’. Rob Purcell for NSG Group, said the Kings Norton premises in south west Birmingham has served them well for many years but they needed more modern facilities to continue to develop its glass products. “This is a very important project for Pilkington Automotive and will make Redditch the consolidated centre for our automotive operations in the UK vehicle automation and electrification initiatives,” he said. The new facility, Purcell said, would be the company’s flagship operation as a centre for excellence in automotive glass and would support 200 jobs.