Government Invests in Aerospace Sector

A multi-million-pound Aerospace Sector Deal has been announced by t he government, building on the UK’s excellence and heritage in aerospace. The Deal aims to transform the future of flight through electrification and autonomy, and commits to increasing gender equality in the sector. The defence and aerospace industry recorded a £10 billion increase in deals over the last 12 months, with the total deals valued at £31 billion. The industry has achieved annual revenue growth of 7% over the last five years, account for 7% of UK exports and employ 338,000 people, according to trade organisation, the ADS Group. The announcement comes as the Business Secretary Greg Clark makes a speech in Bristol today outlining a new Aerospace Sector Deal between the industry and the government. Among the proposals mentioned in the deal, which is part of the government’s Industrial Strategy, are the £250 million Future Flight Challenge. This will go towards developing new ground infrastructure and aircraft technology that will hopefully make the industry more environmentally-friendly. It will also be spent on developing autonomous air vehicles and better airspace management. The programme will receive £125 million funding from the Industrial Strategy Challenge Fund with the other half being match-funding by the aerospace industry. Aerospace giant GKN will also receive £15 million in government funding for a new Global Technology Centre. The centre will be dedicated to a variety of processes, including additive manufacturing (AM), advanced composites, assembly and industry 4.0 processes. Other proposals outlined in the Deal include an expansion of the National Aerospace Technology Exploitation Programme. Like the Future Flight Challenge, it will be joint-funded by government and industry and centre around R&D projects. Supporting SMEs in the UK aerospace supply chain to boost their competitiveness through a new productivity improvement programme. ` Finally, the Deal commits the industry to increase diversity and inclusion by embedding the Women in Aviation and Aerospace Charter. Earlier in the year, 50 companies in the aerospace and aviation sector signed up to the Charter to work towards gender equality in the industry. Virgin Atlantic, BAE Systems, and Bombardier were just some of the signatories. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

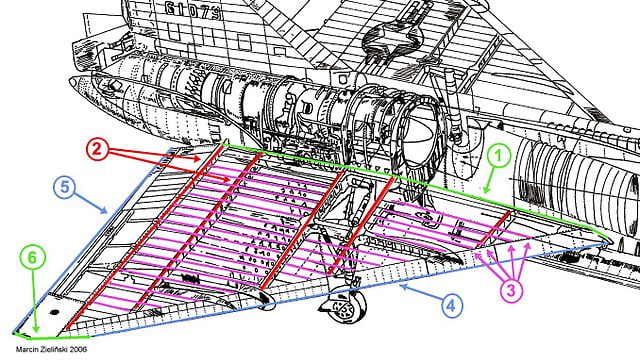

The Fuel-Efficient Aircraft Of The Future

The Fuel-Efficient Aircraft Of The Future : Researchers in Texas, US, are using a Stampede Super-computer to create fuel efficient wing designs for jet planes while developing tools that can aid the industry to become more resourceful in their type of aircraft. By exploring longer wing spans composed from complex composites that can morph during flight, the way we travel by air could be in for some innovative changes. Flying has become considerably cheaper, faster, safer and greener over the last six decades and researchers are now wanting to improve that even further. The development of new, high aspect ratio wings are much greater in size/span than the ones we use in the standard plane today. Improvements in the wing design have the potential to improve efficiency by up to ten percent which would lower both the cost of travel and pollution caused by the transport. The standard plane used today features about fifty percent composites materials all of which are placed in a relatively simple form. New automatic fibre placement machines however could place such composites in complicated curved forms creating tow-steered composite wings. Today’s aircraft uses roughly eighty percent less fuel per-passenger-mile than the original aircrafts of the 1950’s. Which in itself is a huge testimony to the tremendous impact aerospace engineering has had on flight. Despite best efforts, global emissions are still expected to rise over the next twenty years due to a doubling in air travel, even by making small changes and advancements engineers can have a large impact on the economy and the environment. With transportation being the modern backbone of the economy any difference that can be made for the better, even if this is only a fraction of change on fuel efficiency, can have hugely positive overall effects. When new technologies are applied costs and pollution could become lowered with an efficiency increase of ten percent. This process is challenging as there is not huge amounts of intuition on the utilizing of this type of technology. Morphing wings that are able to change shape while maintaining maximum performance regardless of speed, altitude or weight, is certainly a huge advancement in the right direction. Researchers are considering new materials and morphing mechanisms to make their theories become realities in more energy efficient, economically friendly air transportation. Concepts that previously seemed impossible could integrate within society sooner than we think! Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Budapest Airport launches fifth London airport connection with Flybe

Following another record-breaking year for passenger traffic, Budapest Airportâs high expectations for further route development continues with the announcement of its first new airline partner for 2017. Having already confirmed 11 new operations for this year, the Hungarian gateway will welcome Flybeâs three times weekly service to London Southend from May, the airportâs fifth link to the UK capital city. As of this summer Budapest will directly serve 41 country markets, the UK being one of the largest market flown (in terms of eekly seats) from Hungaryâs capital city airport. The London market is by far the largest city pair from Budapest with the irport expecting to serve 1.5 million round-trip passengers to and from the UK capital this year, a notable 14% year-on-year ncrease. Joining existing links to London Gatwick, London Heathrow, London Luton and London Stansted, Flybeâs new service to ondon Southend means Budapest will offer 14 daily flights consisting of over 34,000 two-way weekly seats to London in S17. Commenting on the latest addition to Budapestâs route network, the airportâs CCO, Kam Jandu said: Announcing the arrival of a ew airline partner to the Hungarian market is a great way to start the year. Flybe was looking for a first-class European ity-break destination and weâre certain Budapest will meet all expectations, in fact weâre extremely confident it wonât be long before we will be seeing a frequency increase on this route. He added: Iâd like to take this opportunity to thank all of our irline partners for their support throughout 2016 â exceeding the 11.4 million passenger mark could only be reached through the ontinued teamwork and strong partnerships weâre fortunate to have here at Budapest. Read more at https://www.traveldailynews.com/post/budapest-airport-launches-fifth-london-airport-connection-with-flybe

Aerojet Rocketdyne Creates Rocket Engine with 3D Printer

US-based rocket and missile propulsion manufacturer, Aerojet Rocketdyne has successfully conducted a number of what is called hot-fire tests of its newest rocket engine, the first to be produced by 3D printing technology. The RL 10 upper-stage rocket engine features a core main injector constructed by additive manufacturing technology and is hoped to pave the way for widespread use of the technology in the aerospace and defence sector. Formed in 2013 at the merger of Aerojet and Pratt and Whitney Rocketdyne, Aerojet Rocketdyne has fast become a leader in the aerospace and defence sector, building of the wealth of experience its compatriot businesses bring. The company manufactures and supplies propulsion and energetics to the space, missile defense and strategic systems, tactical systems and armaments areas, in support of domestic and international markets. Testing of its latest rocket engine was carried out alongside the RAMS programme, a research project conceived by the US Air Force and NASA’s Glenn Research Center. The research is geared toward showcasing the potential of additive manufacturing, particularly as it used to manufacture complex components fit for large rocket engines. Eileen Drake, CEO and President of Aerojet Rocketdyne said that the incorporation of additive manufacturing, i.e. 3D printing, was a key strategy in the companyâs growth and would help to deliver more affordable products while not compromising of the every time accuracy needed by the sector. Selective laser melting (SLM) was employed to create the core main injector. It involves using a high-powered laser beam to fuse powered metal together to produce complex, detailed parts. The state-of-the-art manufacturing process produces amongst the most durable components possible which are, of course, perfectly-suited to the extreme conditions to which rocket engines are privy. This is by no means Aerojet Rocketdyneâs first flurry in additive manufacturing and the company has already developed a range of products using the technology. The RL 10 however marks the companyâs most complex use of the technology and is good vision of what the future may like for both the US company and the sector more broadly.

Singapore Airshow Lets Airbus Spread Its Wings

Airbus’ global presence shows no signs of abating after it revealed its latest aircraft at the Singapore Airshow. Its significant presence in the Asia-Pacific region was highlighted by its high-profile presentation at the airshow where potential customers could see first hand its new A350 XWB. Indeed, its appearance has won Airbus one new customer already with others expressing interest. The company also took enquiries which will expand its work in other fields with the Asia-Pacific region. It’s a prime area for expansion as the Asia-Pacific region is the world’s real growth market for civil aircraft. The market has therefore been targeted by Airbus as a new base for key customers where it already provides 31% of Airbus’ orders internationally. The Singapore Airshow gave Airbus another chance to show off its latest aircraft innovation – the impressive A350 XWB. The aircraft is proving very popular with customers in the region and enjoyed a successful presentation at the show where event-goers were wowed by its flying capability. Significantly, the A350 XWB enjoys much of its popularity in the region with Philippine Airlines being the latest carrier to order the aircraft. It will order six initially with another six potentially. The carrier’s specification calls for a three-class layout which will provide passengers with non-stop flights to the New York and the USA’s West Coast from Manila. Airbus’ presence in the region is not simply to provide the market with commercial aircraft. It also provides maintenance and offers training centres as well as other support services. The Singapore Airshow enabled Airbus to extend its presence beyond providing planes for passenger routes with an agreement with the Singapore-based SIA Engineering to provide cabin upgrades, general maintenance and modification capabilities to various aircraft including the the super-sized A380 as well as the A350 and other models.

Airbus On Top As It Moves Towards Zero Carbon

Airbus continues its efforts to reduce the carbon emissions of its operations. While a number of initiatives are ongoing to develop aircraft, systems and operational processes that run more efficiently, its latest innovation is in the use of paint. The Toulouse-based company has designed and built a new paint booth to enable it latest aircraft – the A350 jetliner – to be painted without as much energy demand when compared to typical facilities. The innovative booth in which the planes will be painted will also minimise carbon emissions. Usually, Airbus’ fleet will be decked out in relevant livery through a process which requires 21 to 26 degrees Celsius as a constant temperature and 45% to 70% humidity rate. This has proven challenging as the seasons change with more energy needed to either heat or cool the facility to create the optimum conditions for painting. The new paint booth which has gone into service at the company’s Saint-Nazaire plant will recover heat from the surrounding environment using what is known as the Enthalpic wheel which is essentially a rotary heat exchanger. The system is complemented by a CO2 heat pump (which replaces gas-powered boilers) which brings water up to a temperature of 85 degrees Celsius to furnish the booth with 21 degrees of heat. This eliminates the CO2 emissions generated from gas combustion. Pascal Danthony, project leader, exampled some of the many advantages of the system, not least its capacity to save up to 67% of energy use while drastically cutting carbon emissions. An 86% reduction in CO2 has been achieved. The leftover 14% comes from the electrics in the fans and heat pump. The biggest advantage, however, is the process can be put in place across Airbus’ many paint shops elsewhere. This would make an even greater gain in manufacturer’s green agenda while it has reported payback on investment of four years.

Bombardier and Air Inuit Aircraft Conversion

It has been announced that Air Inuit and Bombardier Commercial Aircraft will be partnering for the passenger-to-freighter conversion of a Q300 turboprop aircraft, with the resulting freighter also including a large-scale door for cargo. As an operator which has worked with the Q300 aircraft for some time now, the organisation has spearheaded the conversion and will also consequently be the launch customer for it. Also, a new STC is to be created under a new license by a third party to further support the conversion. Providing an excellent combination of design and technological advancement, the Q range of aircraft provides a very rugged and performance-led approach best befitting that of short airline journeys undertaken quite regularly. Also as a cost effective range in the Bombardier offering, Q aircraft has successfully achieved a tried-and-tested reputation through use across more than one hundred and fifty operators across the globe. Reputed for its flexibility, Q aircraft are able to adapt to a range of different tasks, including roles not typically associated with airlines such as for maritime patrol, corporate transport and even for cargo service. With over 1,100 of the aircraft already being utilised globally, the quality of the series is clearly defined and proven time over. As Bombardier’s Vice President and General Manager, Customer Services, Todd Young enthused that the conversion may be able to provide a great avenue for the use and benefit with the: Robust, reliable platform that the Q300 aircraft provides. Todd Young also provided thanks to Air Inuit for its assistance in pushing the scheme further towards culmination, bringing both parties one step closer to bringing the amazing new option to the market. As a regional Canadian airline, Air Inuit offers a variety of airline services across its large fleet of some twenty five arctic-adpated aircraft and, like Bombardier, also has a positive industry reputation for offering a high standard and reliable service.