Beckhoff XTS System Revolutionises Motion in Food and Beverage Manufacturing : According the latest United Nations (UN) data, two thirds of the world’s countries expect 50 per cent increase in population between 2019 and 2050. Manufacturers in the food and beverage industry are under pressure to satisfy increasing demand, and ensure that products are safe and comply with numerous regulatory guidelines. For food manufacturers that are willing to innovate, Stephen Hayes, managing director of industrial PC provider Beckhoff Automation UK, explains how a revolutionary new transport system can help.

Increasing productivity and safeguarding consumers’ health are the two main challenges for food and beverage manufacturers. On the one hand, plant managers are expected to speed-up production and diversify their offerings, in order to keep up with increasing demand from more informed consumers. On the other, they must comply with a sector that is among the most strictly-regulated when it comes to hygiene standards.

Food safety essentially relies on the control of contamination. In this sense, transport systems used in food processing are a central concern for the food industry, as micro-organisms can easily accumulate in the different components of a conveyor. If this happens, consumers’ health is at risk and so is the manufacturer’s reputation.

A revolutionary movement

Thanks to its innovative eXtended Transport System (XTS), Beckhoff’s Automation segment has succeeded in turning food manufacturers’ biggest concerns into opportunities. Specifically, to speed up production while improving cleanability.

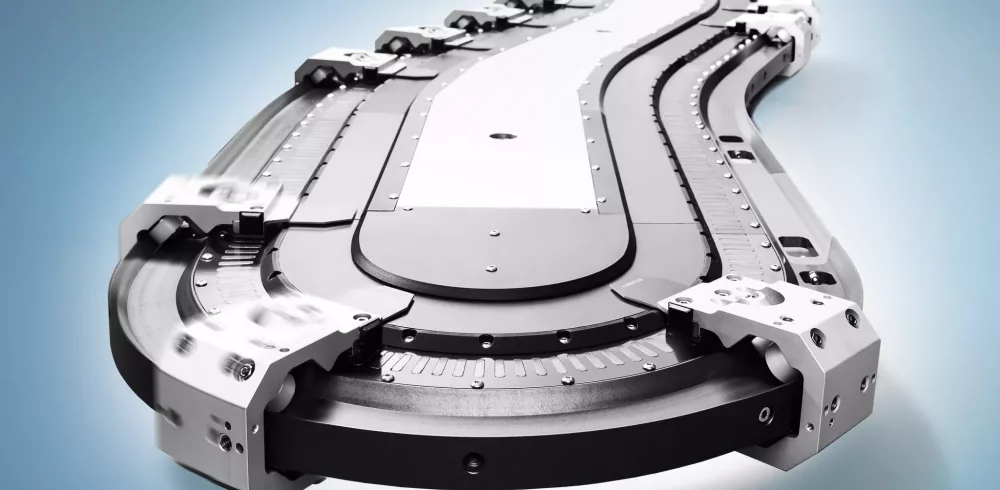

Like any truly-innovative idea, the XTS system is based on a simple, yet ground-breaking concept. Or, in this case, two concepts: first, the possibility for every mover on the track to glide independently; plus the combination of rotary and linear elements to create a customisable track.

In fact, Beckhoff’s XTS transport system combines the benefits of two well-known drive principles, linear and rotary, into a single mechatronic system. This has never been done before and allows manufacturers to create the perfect geometry for their application, no matter how complex.

There are no length restrictions for the entire path and the number of movers can also be customised. In other words, the system is limited only by the available computing power of the industrial PC.

On this track, movers can be positioned in different parts of the belt and travel independently; each with its own speed, acceleration and motion pattern. Alternatively, movers be combined into couples or clusters in order to create hoops that travel together at an established speed.

Additionally, the XTS can be operated in any installation position, so it can be applied with maximum flexibility to match the specific needs of the production line.

More hygiene with improved cleanability

Beckhoff’s XTS is also available in the Hygienic version, a stainless steel model that combines the benefits of this revolutionary transport system, with improved cleanability and resistance to harsh detergents and disinfectant. The XTS Hygienic is therefore perfect for industries where frequent washdowns are mandatory, such as the food processing industry or the pharmaceutical sector.

Severe rules for the hygienic design of transport systems have been established by the European Hygienic Engineering & Design Group (EHEDG). The XTS is EHEDG compliant and meets the requirements for system certification according to EL Class I AUX. It has a protection rating of IP69K and can therefore cope with surfactants, acidic and alkaline cleaning agents as well as with different types of alcohol, disinfectants and even hydrogen peroxide.

The stainless steel body of the transport system ensures a high resistance to delamination, while the absence of edges or undercuts prevents soil accumulation and facilitates cleaning. Additionally, all components of the Hygienic XTS are sealed at the joints with a high-quality elastic material that enables high-pressure washdowns.

Thanks to these characteristics and its innovative approach to motion, the Hygienic version of Beckhoff’s XTS has been shortlisted for the Food Processing Awards 2019 in the category, ‘Process & Packaging Solution or Process’.

Unprecedented challenges call for unprecedented solutions. With the XTS Hygienic, manufacturers can optimise production and ensure that manufactured foods comply with the highest hygienic standards.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News