New UK Additive Manufacturing Centre of Excellence and spin out launched by the University of Wolverhampton with support from EOS and AMCM

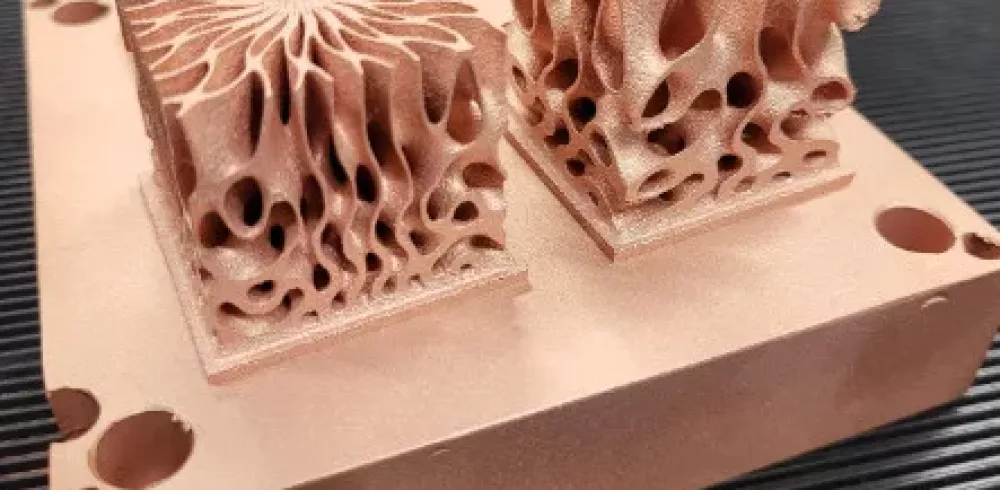

Advanced processes and materials, such as beam shaping and copper, will aid knowledge exchange and enable new design and manufacturing innovations across sectors.

The University of Wolverhampton (UK) and 3D printing global leaders EOS, and AMCM, have today announced they will join forces to launch a new UK Centre of Excellence for Additive Manufacturing (AM). The partnership will provide access to cutting-edge technology from EOS and AMCM, and specialise in the development of advanced materials and processes for demanding applications within industries such as space, automotive, aerospace, electronics, and quantum computing.

Partially funded by the UK’s Regional Innovation Fund (RIF), The centre will be based in the Elite Centre for Manufacturing Skills (ECMS) at the University of Wolverhampton’s Springfield Campus. The centre will be a hub for knowledge exchange and research commercialisation activities, catering for local, regional, and global customers in a wide range of sectors.

Addressing industry hunger for AM innovation

The University of Wolverhampton’s Additive Manufacturing Research Group and its spin off company, Additive Analytics, will lead material and process development activities. Industries ranging from automotive and electronics to quantum computing and aerospace are already expressing interest, highlighting the broad applicability of copper AM for thermal management and electrification, due to its exceptional thermal and electrical properties.

Whilst copper has desirable properties, it is challenging to laser process it, hindering its widespread adoption in AM. The work of the consortium aims to address this by leveraging cutting-edge technologies, processes, and expertise to drive efficiency and reduce material waste.

Decades of AM expertise

Building on the University of Wolverhampton’s 20-year relationship with EOS industry leading machines, the new Centre of Excellence will be bolstered by the adoption of an AMCM 290 FLX the next generation laser powder bed fusion system capable of processing challenging materials, such as copper. The AMCM 290 FLX is a customized EOS M 290 machine equipped with state-of-the-art nLIGHT beam shaping laser technology, high temperature processing capabilities and excellent oxygen control. The system offers businesses early and easy access to the latest technology and research findings.

Professor Arun Arjunan, director of the ECMS and Centre for Engineering Innovation and Research at the University of Wolverhampton, said: “The establishment of the UK Centre of Excellence for copper AM marks a significant milestone in additive manufacturing, setting the stage for a new era of innovation, sustainability, and responsible manufacturing. Future projects will investigate the integration of laser process data and machine learning, and artificial intelligence technologies for efficient material and laser process development.”

Nathan Rawlings, Sales Manager at EOS UK, said: “The UK manufacturing sector has always pushed forward and embraced innovation. Additive Manufacturing with materials such as copper offers huge benefits for product designers, but they can be demanding for manufacturers to work with. This new Centre of Excellence will create and test the processes that enable material benefits to be reliably and consistently realised in real-world manufacturing component manufacturing.”

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News