Smart Factory technology isn’t always straightforward. The market is saturated with sleek digital transformation gadgets, all packed with promises and guarantees. As a result, engineers have struggled to find exactly what they need for modernising legacy equipment, grappled with misaligned technology systems already in place, and experienced digital transformation fatigue. DCO Systems have pushed aside the clutter and asked engineers what they really need.

There are three requirements that continually surfaced in discussions. As a result, DCO have created a wireless Smart Factory monitor that is simple for engineers to use and deploy and fully meets the following requirements.

First requirement: Always-on and battery-free sensors

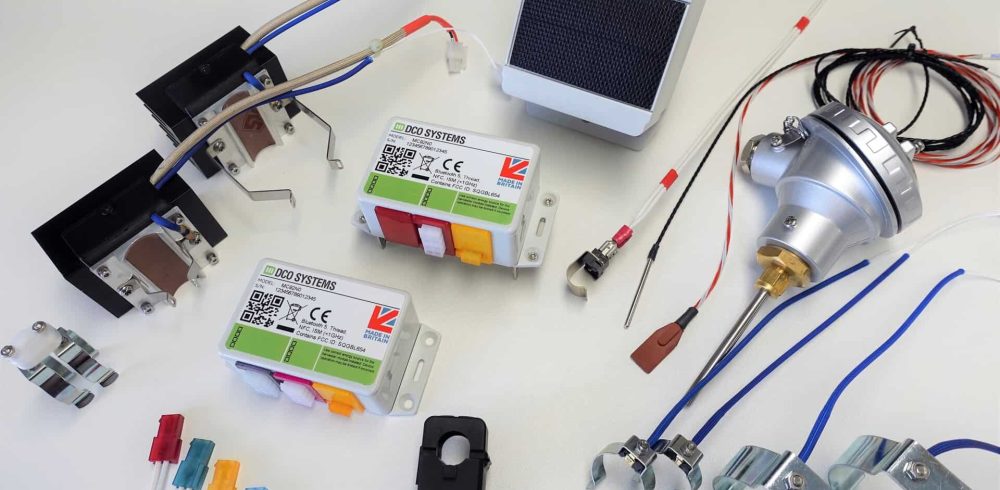

It’s time consuming to determine the correct range, frequency band or power level you need for each sensor, and now unnecessary. DCO’s wireless, battery-free equipment sensors automatically optimise range and frequency choices. Because they are self-powered using energy harvesting technology, they are always-on, no power level to consider or batteries to ever change. The two sensor options include internal or external and harsh environments. If it seems too simple to only offer two sensor types, read on.

Second requirement: Monitor more components at one time

Sensors that run on batteries are often restricted to the number of components that can be measured, because by doing less, the battery runs for longer. This often results in misaligned systems and coverage gaps. DCO’s energy harvesting sensors overcome these limitations and can be customised to significantly extend data collection. This customisation feature makes it possible to gain all of the information you need through one sensor. Furthermore, plug-and-play modules also support your existing devices, integrating inputs from existing analogue and digital sensors into a common remote access and monitoring solution.

Third requirement: Install easily and anywhere

Immediately save on costs and time by avoiding the need to install a power source or hire an electrical engineer. DCO’s sensors can be retrofitted or easily installed to legacy equipment, new machines, over multiple plants and in places with little infrastructure by anyone. DCO have extensively evaluated the practical needs of installers and included colour coordinated connectors, adapters and fittings for many different requirements. The ease of installation and use means that these energy harvesting sensors can be up and running immediately.

____

DCO Systems’ sensors are designed for engineers, making them easier to use and deploy. To get started with DCO’s affordable monitoring tools, go to https://dcosystems.co.uk/mem21/ or email: info@dcosystems.co.uk.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News