In a period of technological change, the fourth Industrial Revolution is said to have started. Around the world, businesses are adapting and investing in future developments in order to find solutions for the challenges of this time. From people living longer to climate changes and increasing urbanisation, solutions are needed in order to continue as resources are depleted, making them more difficult to source and more expensive when found.

For the manufacturing industry, these challenges mean that companies could be having to compete with each other for resources that are essential for the basic needs of modern society, mainly energy and water.

There are a range of developments being made in the manufacturing industry in order to ensure its future. The Internet of Things concept of manufacturingâs future would see further automation, with systems and products communicating with each other in order to control production, cutting the requirement for factory workers and manual assembly lines. The new popular technology Virtual Reality could be adapted to improve productivity and encourage more sustainable production and consumption.

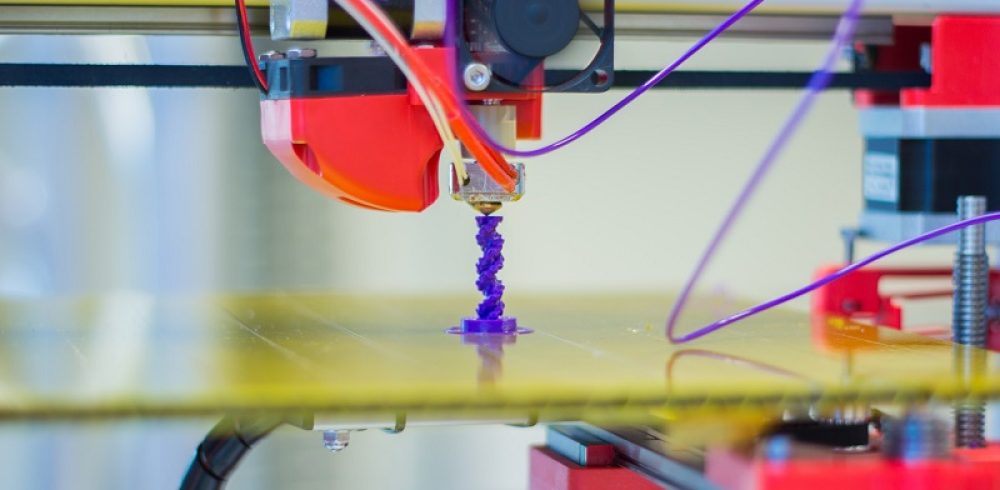

Other technological advances that could be used in the production systems of the manufacturing industry includes the use of Nanotechnology and 3D Printing. These innovations could allow for more flexibility and speed up the time needed to manufacture bespoke components or requirements. Robotics could lead to everything being complete without the need for humans.

Big Data could revolutionise how manufacturers make products and deliver services whereas the improvements being made to GPS satellite technology will allow manufacturers to perform at an optimal level, with possibilities for supply chain issues to be identified and fixed in real time.

Technology can be adapted in various ways in order to improve efficiency and sustainability in the manufacturing industry. However, by using technology, manufacturers also require energy and to use different types of non-renewable materials. This means that manufacturers could be replacing one unsustainable act with another.