A fully digitised and automated factory with super-efficient robots and non-stop machinery and along with an integrated supply chain and office software may be the ideal image of manufacturing Industry 4.0 at its best. However, the reality of manufacturing in the UK today is a very different picture.

Small and medium-sized manufacturers in particular may feel that they have been left behind by the smart factory movement due to prohibitive costs and complexity. Budgets are being squeezed from every angle, we’re experiencing an extremely tough economic climate following COVID and Brexit, and inflation is rising to worrying levels. Improving operational efficiency and increasing productivity must be high on the agenda for many manufacturers. And this is where low-cost digital technology can come into its own.

What is Industry 4.0?

Industry 4.0 is still evolving but in practical terms, it is a variety of means by which manufacturers are integrating new technologies, including Internet of Things (IoT), cloud computing and analytics, and AI and machine learning into their production facilities and throughout their operations. Industry 4.0 technologies allow your production lines, business processes, and departments to communicate regardless of location, time zone, platform, or any other factor.

Industry 4.0 is about connecting digital systems together to make manufacturing businesses more

productive, competitive and resilient. However, due to the complexities of the manufacturing process it can be very difficult and costly to find a system that delivers complete integration.

FourJaw, the company behind an affordable and accessible plug & play machine monitoring solution believes that one of the first steps on this journey is for businesses to look at the resources they already have at their disposal and ask themselves whether those resources are being used in the most efficient ways.

How Smart technologies can make your production machinery work harder

Most of the manufacturing businesses FourJaw come across estimate machine utilisation at between 50% and 60%. However, after implementing its ‘plug and play’ manufacturing analytics software, the data shows that actual utilisation rates are, on average, between 20% and 30%.

For a lot of businesses, the first instinct is to invest in new equipment to help increase efficiency. In many cases, with the right information at their fingertips, those businesses can significantly improve Overall Equipment Effectiveness (OEE) without having to invest in new kit, simply by tapping into the capacity in their existing machinery.

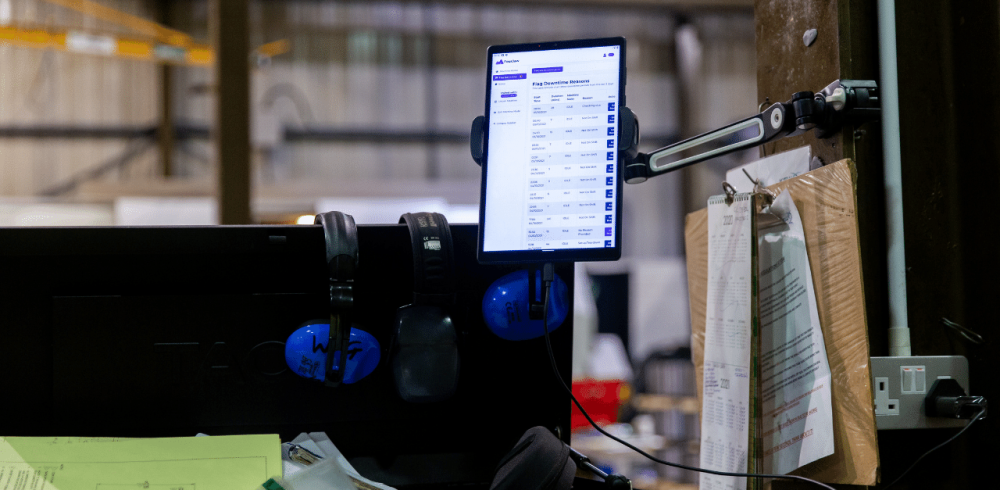

FourJaw’s machine monitoring solution gives manufacturers the data visibility to improve their shop floor productivity by understanding the main causes of downtime.

Many manufacturers don’t realise that this type of ‘plug and play’ monitoring exists, or how quick, easy, and cost-effective it is to implement across an entire manufacturing facility, giving them a holistic view and enabling them to address productivity across the site.

How machine monitoring can increase utilisation and production capacity

Machine monitoring software from FourJaw has recently driven a 14% uplift in machine utilisation and 65% increase in parts output at brass cabinet hardware manufacturer Armac Martin. The company used data from FourJaw’s machine monitoring platform to increase its production capacity and meet a surge in demand for its product range.

Very quickly the data highlighted which machines were being well-utilised and in high demand, and those that were under-utilised and whose function was becoming redundant. The data provided Armac Martin with clear visibility of the production schedule and machine capacities.

Production Director, Rob McGrail, commented “FourJaw helped to quantify our initial thinking and put some value to it so that we could make more-informed data-based decisions. The recent product enhancements have made FourJaw a solution that is delivering real benefit from the top floor to the shop floor, it’s the team’s operational tool”.

This knowledge gave them the confidence to sell one piece of under-used machinery and invest in a more appropriate machine that would meet the growing demands of their customers. The purchase of the new machine is expected to reduce the overdue raw material orders by more than 60 per cent. Read more about how British manufacturer, Armac Martin benefited from deploying plug-and-play machine monitoring from FourJaw across their shop floor.

The benefit of real-time data

Gathering the right data in the most cost-efficient way is key. Without it, gaps and inefficiencies are not always obvious. With accurate, real-time data as the starting point, managers can quickly see those gaps, and put processes in place that will drive production efficiencies and invaluable cost savings.

Easy-to-use machine monitoring systems are set to become an invaluable tool to guide manufacturers in their journey through the fourth industrial revolution.

Read more about what Industry 4.0 is, and what it looks like for your business, by downloading FourJaw’s free ‘No Bull Industry 4.0’ guide.

FourJaw will be exhibiting at the Advanced Engineering show located on stand G80 in the ‘Connected Manufacturing’ zone.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News