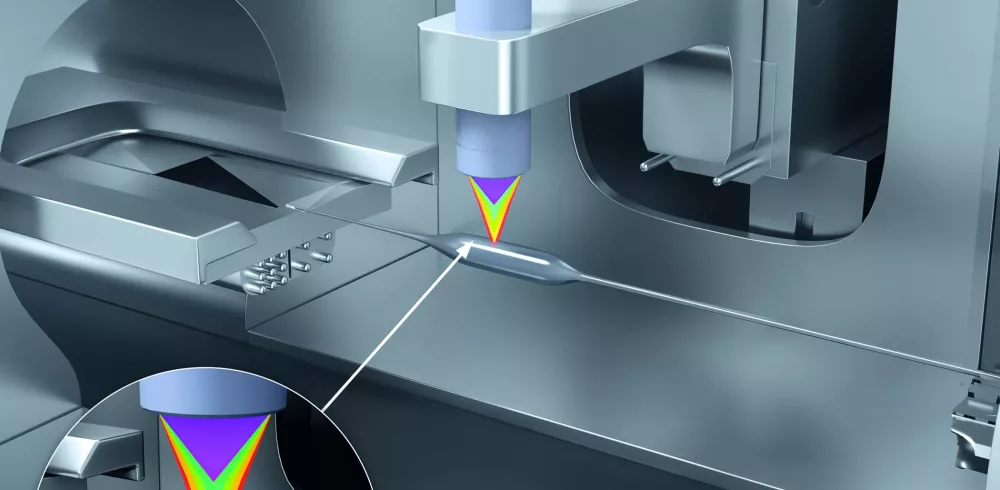

Developed for ultra-high precision in the micron range, SICK’s innovative and compact OD7000 displacement sensor reliably measures tiny distances in challenging applications cost-effectively. Comprising a separate controller and sensor head that are both extremely compact, the OD7000 is purpose-built to fit into the tightest machine spaces.

The SICK OD7000 is a 1D laser distance sensor that measures differences in height accurately even on challenging materials. Its tiny light spot precisely targets the object and outputs a precise measurement regardless of the colour or surface material and even measures curved surfaces accurately.

Challenging Applications

The SICK OD7000’s chromatic confocal technology enables highly-precise measurement on a wide range of materials, from black to transparent, diffuse, reflective, and even curved surfaces. The SICK OD7000 can inspect, for example, whether a target object is smooth or is positioned correctly. It can measure holes or check if a material has the desired thickness. Using one sensor head, it can measure up to three very thin layers simultaneously, even if the material is transparent.

It is therefore ideal for diverse measurement duties where micron precision is required, mastering challenging applications in electronics component manufacture or consumer goods packaging. It is likely to find applications in EV battery manufacture, measuring the thickness of glass and films in consumer goods and pharmaceuticals, or multi-ply toilet and tissue papers, for example.

Meticulous Development

“SICK has worked hard and taken some time to develop the OD7000 meticulously,” explains Nick Hartley, SICK’s UK Product Manager for Distance Measurement. “The result is a highly-precise instrument that offers manufacturers with some of the most challenging measurement requirements a real opportunity to output precise data, without complicated set-ups or super-expensive equipment.

“Using a 1D laser distance sensor with the performance of the OD7000 enables machine integrations to achieve high levels of material inspection and thickness determination, that might otherwise only be possible with much more expensive equipment.”

Easy to Set up and Install

Two controller types both with EtherNet interface and a choice of 3 sensor heads span measurement ranges of 600 μm, 4mm, and 10mm with corresponding resolutions of 25 nm, 180 nm, and 400 nm.

The OD7000’s engineering tool has an easy-to-use graphic interface that allows the user to visualise the installation and configure the controller rapidly, while additional settings are available for more advanced applications. The OD7000 also offers serial RS-232 / RS-422 or Ethernet TCP/IP interfaces as standard.

One of the OD7000’s controllers offers the further cost and space-saving benefit of being able to define an encoder input as a trigger for the output of measurement data, so that a separate encoder is not required as part of the machine set-up. The SICK OD7000 has a 10 kHz maximum sampling frequency, meaning all variants offer the same high performance, enabling stock control to minimise inventories.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News