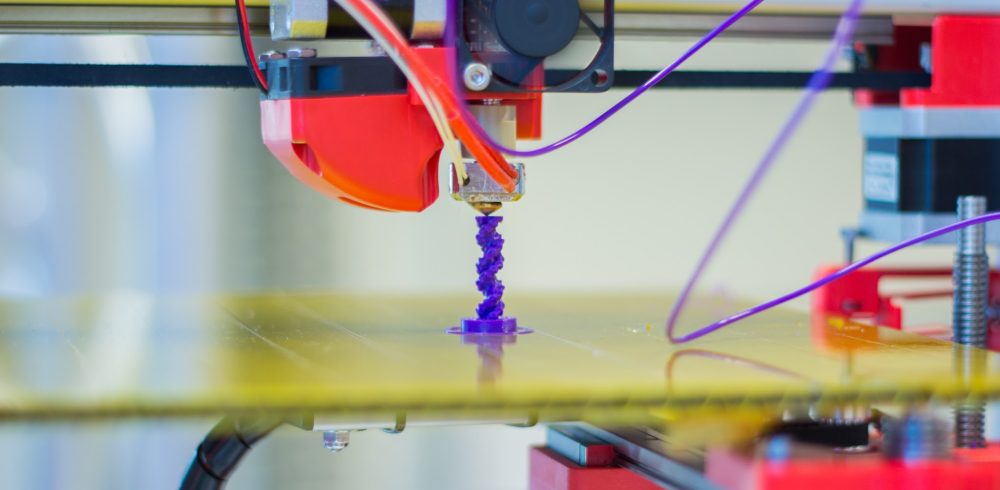

Team-working Robots Build 3D Printed Structure : A group of innovative scientists from Singapore have developed a technological advancement that allows two robots to collaborate together to create a 3D-printed concrete structure.

The team from Nanyang Technological University (NTU) have pioneered the way for groups of robots to produce large printed structures that could have huge implications for the time and efficiency of future builds.

Assistant Professor, Pham Quang Cuong, published the work of himself and his team at NTU in Automation In Construction. The development comes forth as a new form of multi-robot technology that follows on from earlier development, the Ikea Bot.

The Ikea Bot was a project that saw two robots assemble an Ikea Chair in an impressive time of 8 minutes 55 seconds. The latest innovation aims to emit the same philosophy on a much broader scale, which can allow for unique concrete designs to be created due to a specially formulated cement mix, suited to 3D printing.

The 3D printed structure measures 1.86m x 0.46m x 0.13m and was able to be produced in a speedy 8 minutes. The model took two days to completely harden and another week to achieve full strength before it was then ready for installation.

The vision behind the project stands as the creation of a group of robots who can be transported efficiently to a work site, where they can then begin large scale printing of concrete structures and quickly move onto new projects.

Currently huge printers are required in order to product such structures, which are in fact larger than the finalised printed product. This is unfeasible on construction sites that can often have space constraints. However, having a line of robots who can work in unison to print in sync with one another, means that as long as the robot has enough space to move around a site, theoretically, structures can be printed anywhere.

With further developments already in motion, the future for 3D printing remains as exciting as ever.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News