By 2030, it is predicted that over 85 million positions will be unfilled across the globe, hampering economic growth and presenting an opportunity for businesses to introduce more automation. Here, Tom Cash, a director of industrial parts supplier, Foxmere, identifies three major trends that are likely to shape the demand for automation over the next 12 months.

Economic factors like Brexit, component shortages, supply chain disruption and the lingering effects of the COVID-19 pandemic are exacerbating the problems created by a global shortage of workers. As a result, businesses must find new ways to build up their resilience and cope with unforeseen changes.

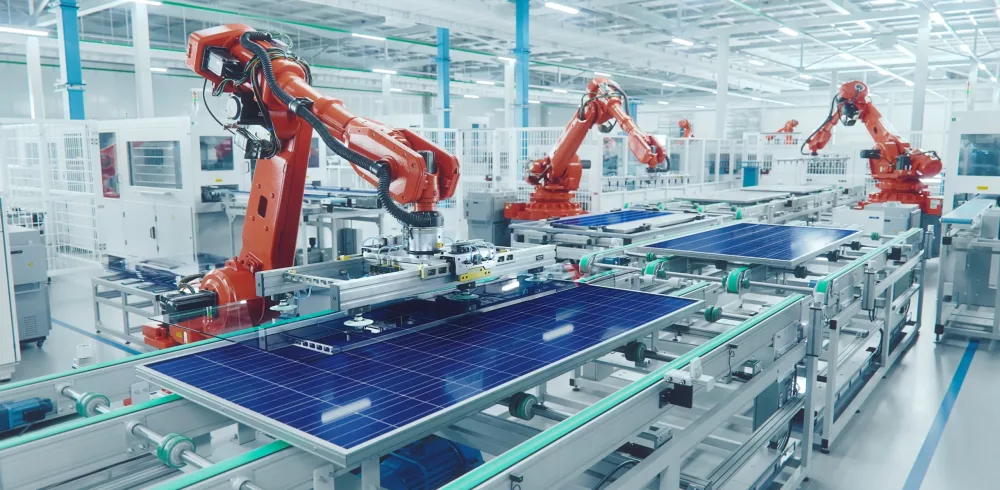

Automation systems are the cornerstone of a revolution that is reshaping the way we work, manufacture goods and harness energy. Continuously evolving with industry trends, these systems now incorporate artificial intelligence (AI) and data-driven decision-making, expanding their applications into various sectors, including logistics, healthcare, agriculture and more.

This transformation extends not only to how we produce goods but also to how we power our world, making automation systems essential building blocks of progress in the modern era.

Sustainability

Sustainability has been a topic of interest for years, however it is likely to continue being relevant for the foreseeable future with the ever-pressing issue of the climate change crisis and global warming.

According to Climate.gov, there has been an increase of one degree Celsius in global average surface temperature since the pre-industrial era (1880-1900). Although this increase seems minimal, the consequences are substantial due to a significant increase in accumulated heat. This results in seasonal temperature extremes, reduced snow and ice coverage and intensifying rainfall.

Sustainability is now a key factor in the adoption of automation, with a need for enhanced energy efficiency and better recycling systems. An increase in the demand for automation that is energy efficient, capable of reducing waste and optimised for eco-friendly production processes is expected.

From smart manufacturing to precision farming, these technologies are increasingly being tasked with minimising resource consumption and promoting a circular economy.

Automation is also increasingly used in the waste industry to improve efficiency, safety and sustainability. Automated sorting systems use robotic arms, sensors and conveyor belts to sort through and organise, for example, incredible quantities of rubbish for recycling.

AI

According to Statista, the manufacturing industry accounted for 65 per cent of the AI robots used in 2022. The collaboration between AI and industrial robots will likely only increase demand for automation parts as these systems become smarter and can be used in many different industries.

As AI technology continues to advance, automated systems will also increase in adaptability and capability to work alongside humans. This combination is driving the demand for digitisation technologies that can handle complex, dynamic tasks.

What’s more, machine learning is an AI technique that teaches computers to learn from experience, mimicking human characteristics and actions. Another AI technique used is edge computing, which enables automated systems to analyse real-time data and make decisions much quicker than humans without having to return data to the cloud for processing.

Predictive maintenance also uses AI technology to capture data and detect potential problems with equipment. This information is then used to predict and prevent unplanned machine breakdowns, significantly reducing costs and allowing the production line to continue to run.

Reshoring

Global events, including the pandemic and geopolitical shifts, have exposed vulnerabilities in global supply chains. As a result, many companies are reevaluating their manufacturing strategies and considering a return to local or regional production.

Reshoring, or bringing production closer to the point of consumption, is gaining traction. This often involves the need to enhance productivity, reduce costs and improve quality to remain competitive, driving a higher demand for automation technologies to streamline manufacturing processes and maintain or increase production levels.

Over the next 12 months, we anticipate a surge in the demand for automation to facilitate reshoring efforts. These technologies will enable efficient, flexible and cost-effective local production.

With reshoring gaining traction, it’s vital that companies have a reliable supplier to keep the production line up and running. These trends are not only shaping the demand for digitalisation but are also reshaping industries as we know them too.

Organisations that recognise the importance of these trends and invest in automation will thrive in the evolving business landscape and contribute to a more sustainable, efficient and resilient global economy over the years to come.

To ensure that your business is amongst those thriving, contact Foxmere today for a no-obligation quote on automation equipment ranging from replacement or obsolete parts to complete robotic systems.

Contact Foxmere: www.foxmere.com 01922 666 035

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News