The UK manufacturing sector traditionally has fewer robots per 10,000 workers than some of its European counterparts, for example Germany – but the rise of ‘cobots’ could help to change this according to Actuated Valve Supplies.

Within UK manufacturing, the proliferation of SMEs could be one reason why large robots that take a lot of time to program have not found widespread popularity.

Figures from Statista show that in UK manufacturing , nearly a million people work for companies with fewer than 100 employees, and over 1.5 million are employed by firms with a workforce of less than 500.

In contrast to this, manufacturers with 500 or more employees account for around 850,000 UK manufacturing jobs – so with the focus on SMEs, automation must be suitable for small production runs and quick changeover.

What are cobots?

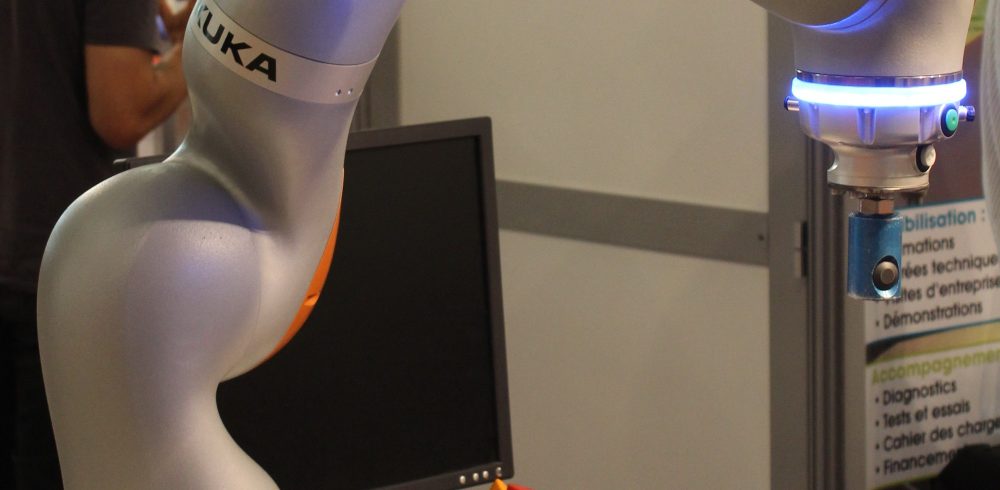

Cobots are collaborative robots, and are part of the collaborative automation platform developed by Universal Robots, which continues to expand.

At Automatica 2018 in Munich, the brand unveiled the latest addition to their cobot line-up, the e-Series , which combines high-precision motion with a wealth of safety features like customised stopping time and distance.

Universal Robots are not the only developers of collaborative robots, but company president Jurgen von Hollen hopes the e-Series will help them to remain as market leaders.

“The global cobot market is expected to continue to be one of the key growth drivers in the automation market in the coming years,” he added.

How can cobots help SMEs?

Cobots have significant potential for companies of all sizes, but for SMEs some of their features are especially compelling, with Universal Robots suggesting that an untrained operator can mount and program a cobot’s first basic task all within an hour of unpacking it.

Most customers report that it takes half a day to get their cobot fully up and running, and this means deployment can be a matter of hours, rather than the weeks it may take to deploy a traditional automated robot.

Programming the machines is easier too, with intuitive touchscreen tablets and the ability to directly move the robotic arm to each waypoint in order to record its desired route.

This easy and fast setup process all means that for manufacturers with small batches and who need to use the same robot for multiple applications, redeployment is fast and easy too.

A faster, safer future?

The use of robots is not just about speeding up manufacturing output; it can also make it safer, by removing the need for humans to work in dangerous jobs, or even in those that raise the risk of repetitive strain injuries.

Cobots work alongside humans in many environments, and according to Universal Robots, once safety risk assessments are completed, 80% of their robots are able to work without the need for additional safety shielding.

As innovations like tablets, touchscreen and visualisation techniques like augmented reality continue to unlock new and easier ways for untrained individuals to program robots – and especially cobots – automation technology could yet be seen in far more UK manufacturing SMEs than has previously been the case.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News