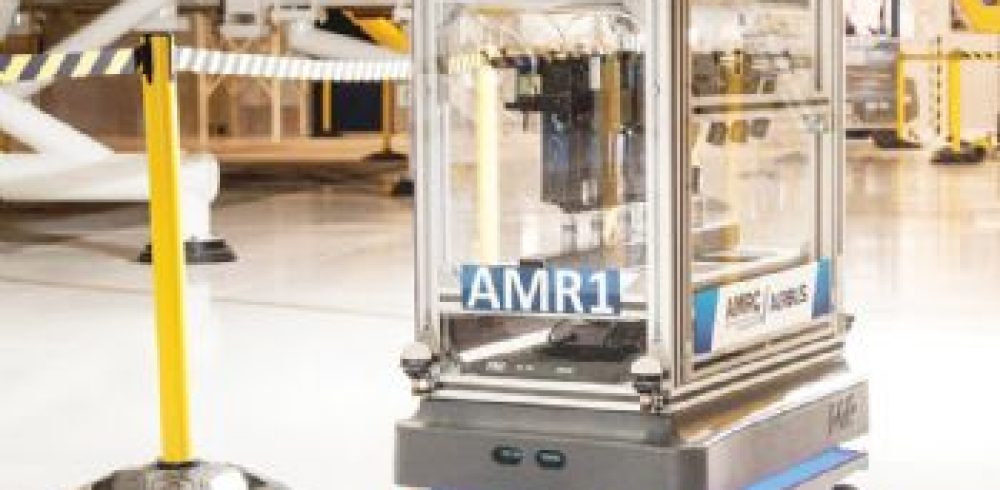

A collaborative research project involving engineers at the University of Sheffield Advanced Manufacturing Research Centre’s Integrated Manufacturing Group could lead to an entire aircraft wing assemblies being transported by autonomous robots at the Broughton Airbus factory in North Wales.

“Supervised trials of the robots have already taken place, and it has been estimated that using them could save the whole-time equivalent of one operator per shift at Airbus, freeing them to work on other tasks and ultimately improving shopfloor productivity,” said AMRC senior project engineer Lloyd Tinkler. “This outcome has led to Airbus exploring opportunities where such robots could be used to optimise processes, including specially adapted versions to pull trolleys with aircraft parts and tooling already in use at the Airbus site.”

Started with the developing of a safe automated system for delivering tooling within the facility, the ambitious project could be expanded to further benefit from using small autonomous robotic vehicles on the shopfloor.

“This project has been our first trial of autonomous mobile robots (AMRs). We enhanced the standard off-the-shelf technology to make it safe and suitable for our factory environment, and we are now working towards its roll-out to other Airbus sites world-wide,” said Amer Liaqat, technology manager at Airbus UK.

“We can see the potential to go even further and work with the AMRC to develop autonomous mobile robots for precision assembly tasks such as component positioning and certification. Developing it further, we could see this technology being used to transport an entire aircraft wing between factories at Broughton,” Mr Liaqat added.