A working scaled replica of the Rolls-Royce Thrust Measuring Rig (TMR), better known as the “Flying Bedstead” has been built by engineering students at the University of Nottingham.

Built and tested by Rolls-Royce in Hucknall, the TMR was the first jet-lift aircraft to fly anywhere in the world, with its inaugural tethered flight taking place in 1953, followed by its first free flight the following year.

Now, to celebrate what would have been the original developer Alan Arnold Griffith’s 130th birthday, as well as the 70th anniversary of its first tethered flight, Engineering students have spent their third year building a representative copy of the experimental aircraft, using modern methods such as 3D printing and open-source electronics, which was unveiled at an exhibition this week.

Associate Professor Mark Jabbal, Aerospace Engineering Programme Director at the University of Nottingham, said: “Currently, there’s only one TMR on static display in the world, at the London Science Museum, so having our students build this working scaled replica means that more people around the country will be able to get a glimpse of this fascinating piece of aviation.

“Not many people are aware that Nottinghamshire is the birthplace of vertical jet lift technology, so this project has not only provided students with practical knowledge, but it’s also given them a greater understanding of our heritage and the part we played in aviation history.”

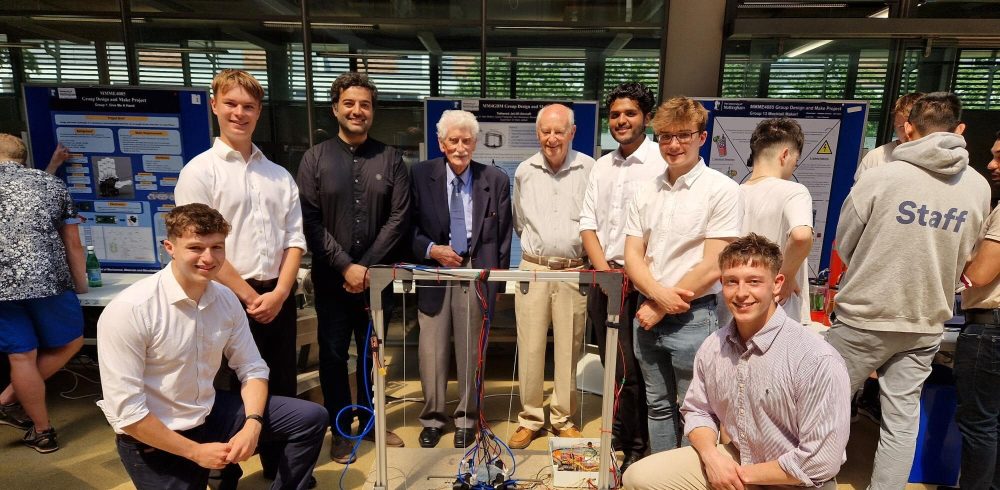

The replica was unveiled, alongside 30 other student projects, with several special guests in attendance, including AA Griffith’s son, John, and grandson, Harvey, as well as Les Fenwick, a former Rolls-Royce TMR Engineer who worked on the original “Flying Bedstead” in the 1950s.

He said: “As soon as I saw the replica, I was taken back to when I was an apprentice more than 50 years ago and I thought: ‘That’s it’. The students have done a truly marvellous job and it’s made me feel a little bit emotional that my colleagues who are no longer with us aren’t able to see this fantastic recreation of the TMR we all worked tirelessly on. This time 50 years ago, we were responsible for a world first, and now, the students have done the same.”

John Griffith said: “It’s a great honour and privilege for me to talk to the students about their work and see the TMR. This replica is keeping my father’s idea and memory alive, so seeing it on what would have been his 130th birthday makes it even more poignant. Sadly, he passed away 60 years ago but I think he would have been very intrigued and impressed by what the students have created if he were here today – while still making sure to take a very critical look at the inner workings, of course!”

Joseph Elliott, a Mechanical Engineering student who was part of the group to recreate the TMR, said: “Recreating the TMR in a compact form using modern manufacturing techniques proved to be a very challenging and ambitious project. Each member of our team contributed a huge amount, and we are all very proud of the outcome.

“Some of the main issues we encountered were the design of the pneumatics system, which allows the device to stabilise itself using compressed air and the electronics/control system. Also, development of the gantry safety system, which protects both the device and viewers, required much consideration. We are grateful to have had the opportunity to replicate this piece of history and very thankful to those who came to see it unveiled.”

Now the model is complete, it will be kept at the university until it can go on display at the Rolls-Royce Heritage Centre and the Hucknall Flight Test Museum, where the original TMR was built and tested 70 years ago, when it reopens in August.

Mark added: “It’s a testament to the hard work of the students – Joseph, Alex, Brandon, Ciaran, and Sam – that the replica will eventually be exhibited at the Hucknall Flight Test Museum, and I’ve been very impressed at how they’ve managed to stay true to the original designs while incorporating modern techniques into the process.”

To find out more about the university’s Mechanical Engineering course, please click here.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News