3D Printing Helps Build Wind Tunnel

The new wind tunnel model of the LEONARDO tiltrotor AW609 manufactures developed by CRP Technology for Leonardo Helicopter Division (Leonardo HD, formerly known as Agusta Westland) is among the most interesting and significant applications in the aerospace sector. This project allowed CRP Technology, once again, to highlight the perfect union between advanced 3D printing technology (Selective Laser Sintering) and Windform® high-performance composite materials. Thanks to the Windform® materials, it was possible to complete and test the model in the wind tunnel within a very short time, with excellent results and with high-performing mechanical and aerodynamic properties. The project related to the manufacturing of some external parts (nose and cockpit, rear fuselage, nacelles, external fuel tanks, fairings) of the wind tunnel model (1:8.5 scale) for the prototype of the new LEONARDO HD tiltrotor AW609, made by Selective Laser Sintering technology and Windform® XT 2.0 Carbon-composite material, both supplied by CRP Technology. This model was designed, manufactured and assembled under the supervision of Leonardo Helicopter Division by Metaltech S.r.l. for a series of dedicated low speed wind tunnel tests. The tests were intended to cover a standard range of flight attitudes to be performed at Leonardo HD wind tunnel facility and at Politecnico of Milan for the high angles of flight envelope. During the different test sessions various external geometries have been changed and checked in order to understand all the aerodynamic phenomena. The external main components redesigned and manufactured include: fuselage and nose components, fairings, nacelles and spinner shapes, empennage, wings and flaperons. As part of a thorough review of the aircraft behavior, Leonardo Helicopter Division has performed a high speed test campaign at NASA Ames Unitary Plan 11 by 11 foot transonic wind tunnel.

The Future of Transportation

The Future of Transportation : The first event of 2019 for Measurement Manufacturing Network (MMN) led by the National Physical Laboratory (NPL) North of England in conjunction with the University of Huddersfield took place on 15th January at the 3M Buckley Innovation Centre in Huddersfield. The Future of Transportation event was organised by NPL which is the UK’s National Measurement Institute, and a world-leading centre of excellence in developing and applying the most accurate measurement standards, science and technology available, attracted an audience of over 70 people from different business backgrounds including both large organisations and small and medium-sized business (SMEs) as well as representatives of academia, and technology providers. The talks focused on light weighting and composites; electric and hybrid propulsion; and connected and autonomous vehicles. The speakers included Rowan Eagen from Northern Automotive Alliance, Nigel Schofield from University of Huddersfield, Martin Sharp from Liverpool John Moores University, Gareth Hind and Andre Burgess from the National Physical Laboratory. Their presentations helped attendees to develop a better understanding of the complex topics from different perspectives. In addition, the representatives from Leeds City Region based business support programme gave the audience an update about available funding options. The audience was entertained by a usual measurement competition which involved estimating the distance from Huddersfield to Dominican Republic in kilometres. The winner was a representative of Lancereal Limited located in Huddersfield and received a prize of NPL mug and socks! The event received very positive feedback, and many positive comments: “Great event to gain awareness and network with others, gaining different perspectives”. “Good mix of presentations at different levels”. “It was a fascinating insight into future developments”. The opportunity to network with likeminded people is key to the success of events like The Future of Transportation and delegates often find potential customers and answers to issues they face in their day to day business. NPL established a North of England Regional Centre with the aim of supporting regional manufacturing, in particular SMEs, to help them achieve their full potential to become competitive within a challenging worldwide market. NPL has a range of ways to support business such as measurement and product verification related services to help SME Manufacturers identify appropriate validation methods within their business with the aim of increasing efficiency, reducing waste and improving product quality. The NPL MMN has been created to make this process as simple and seamless as possible with free membership to all manufactures. The aim of the Network is to enable the members to benefit from NPL’s expertise with the view of optimising productivity and increasing confidence in their products, keeping their businesses at the forefront of measurement and validation technology. Following the feedback received during previous events from the MMN members, the next event will take place on 16th April at the 3M Buckley Innovation Centre in Huddersfield and will cover the topic of Succession Planning and the Skills Mix for Manufacturers. To book your place at the event, visit https://www.eventbrite.co.uk/e/npl-mmn-event-succession-planning-the-skills-mix-for-manufacturers-tickets-54279467348 or call NPL North of England 01484 505713. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

R&D Division Opened in York by Irish Manufacturer

A new R&D Division has been opened in York by a Republic of Ireland-based temperature and pressure instrumentation manufacturer that aims to expand its operation to mainland UK. Eurolec Instrumentation opened its new research and development department at the Science Park in York. “We’re delighted to announce the opening of our York office. The new office is located close to the university, which provides an excellent pool of talented engineers who are capable of creating the complex systems required to provide simple-to-use solutions, which will allow users to monitor a wide network of systems that aim to improve lives,” said Martin Williams, Eurolec Chief Engineer. There are already three members of staff based in the new division and further expansion plans are due to happen later this year. With the latest R&D investment, the company is now looking to provide Internet of Things (IoT) solutions for clients as part of an expanded product and service-based offering. Along with sister company Cirrus Research based in Hunmanby, Eurolec also plans to start offering distributed noise monitoring to provide live monitoring and historical noise data analysis using cloud technology. In addition, further investment has been made in the company’s website to transform it into an e-commerce platform, which has recently been launched. With 40 years’ experience in the design, manufacture and supply of portable temperature and pressure instrumentation, Eurolec’s range of precision thermometers, probes, infrared thermometers, manometers and temperature calibration sources are exported globally.

Syncron Launches New Learning Platform

Syncron Learning has just been launched by SyncronTM, a provider of cloud-based after-sales service solutions focused on empowering the world’s leading manufacturers to maximise product uptime and deliver exceptional customer experiences. It is a powerful new e-learning platform designed for customers to continually develop and enhance their ability to use Syncron solutions. Manufacturers are seeing a shift to servitisation more than ever before, where organisations transition from selling one-off products to selling the output or value that products deliver. This new way of doing business impacts after-sales service and as a result, it has become critical to shift from a reactive, break-fix service model to one focused on maximising product uptime, or preemptively repairing equipment before it ever fails. Syncron’s dedication to its customers’ success is paramount, and this new e-learning capability gives customers the power to further improve and optimise their after-sales service organisations. With e-learning platforms, participants learn nearly five-times more material without increasing time spent in training. Syncron designed and developed its initiative – a first-of-its-kind industry offering – from scratch. The new platform aims to give customers the power to hone their skills and capabilities to more rapidly deliver business value with Syncron solutions. Ultimately, it enables customers to further increase financial performance and improve their own customers’ experiences. “We are thrilled to bring this new, unique offering to our customers around the world. While many other learning functions are templatised and static, Syncron Learning is interactive and tailored to each individual user. As after-sales service increases in importance, reliable, cost-effective training and continuing education will be fundamental to success,” said David Reiling, Chief Customer Officer at Syncron. With more than 200 active users already, the mission of the new tool is to empower every user to attain a higher level of knowledge more efficiently and at a lower cost. Specific benefits of state-of-the-art, online platform include: Ensuring new users can quickly onboard and adopt Syncron solutions on their own terms Provide additional training and learning opportunities for existing users to steadily increase their knowledge and product capabilities Tailored curriculums based on product and user role Interactive, fun training courses built by instructional designers and product experts within Syncron Syncron Learning currently offers four levels of learning options, including Standard, Professional, Expert and Customised. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

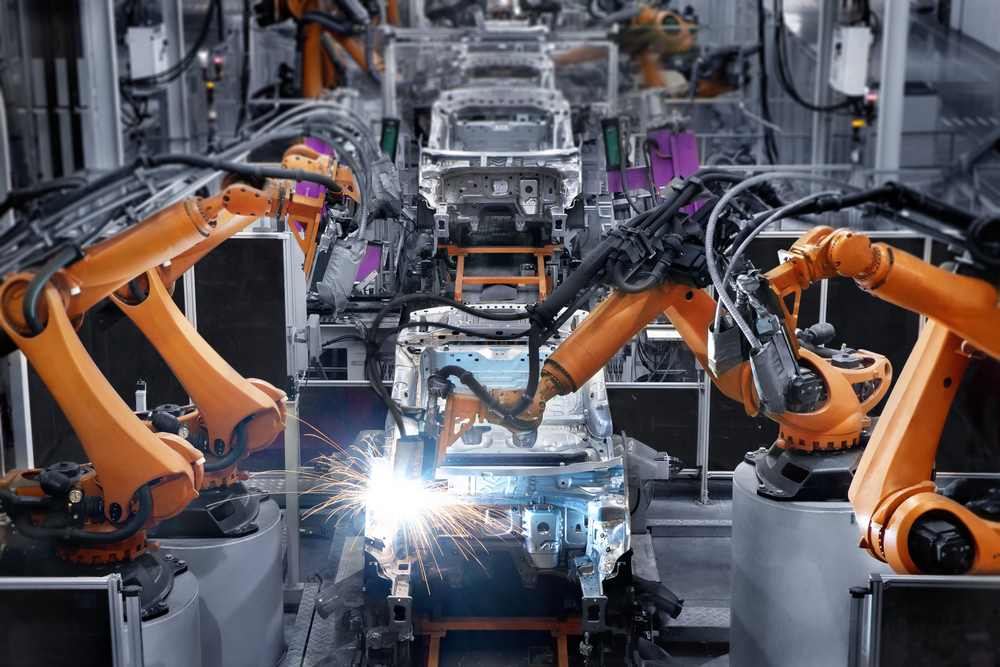

How the Robot Revolution Affects Manufacturing

Since the inception of the assembly line, manufacturers have continually searched for ways to improve their efficiency. In the past few decades, robots have taken over some of the functions of human workers, mostly in repetitive, routine tasks. This has caused alarm for some who are worried about robots taking their jobs. So how exactly is the robot revolution changing the manufacturing business? Here’s what you need to know. The State of the Robot Revolution Last year, an 11-inch armless robot named Jibo — a so-called “social robot” — became the latest example of a clear phenomenon: more capable robots are coming soon. In truth, they’re already everywhere: in planes, in cars, in operating rooms, on assembly lines, in the military, and on the last mile. As more robots appear, a new product architecture and more computing power become essential. In 2015, Gill Pratt, who oversaw robotics technology at the Defense Advanced Research Projects Agency (DARPA), said “Improvements in electric energy storage and the exponential growth of computation power and data storage had enabled robots to learn and make decisions informed by the experiences of other robots.” Does that sound frightening? Robots learning from other robots? In a sense, it leads to a larger consumer interest because the smarter robots are, the more helpful they are to humans. The consumer market will approach $100 billion in the coming years. Today, most of the world’s robots are used in factories. What’s different is that those robots are smaller, more observant and more cooperative than their predecessors. Venture capitalists are flooding the robot market, which means we will be seeing more of them in our distribution centers and warehouses soon. And it’s not just manufacturers who are utilising robots. Companies from retailers to hotels are implementing the use of smarter machines. So, not only will more robots become available, the manufacture of the units, all of their parts, and their internal chips and other technology will greatly affect the robotics industry. The Changes Wrought By Bots The upcoming “robot revolution” will change the global economy over the next two decades, cutting the costs of doing business, as machines take over jobs like caring for the elderly or flipping burgers. Robots can already perform manual jobs, such as vacuuming the living room or assembling machines. The development of artificial intelligence (AI) means computers and robots are improving their ability to “think”. They are on the verge of being able to perform analytical tasks once seen as requiring human cognition. This begs the question: what jobs could eventually be taken over by machines? Bank of America Merrill Lynch’s analysts predict the following jobs to be at risk: Burger Flippers, Manufacturing Workers, Financial Advisers, Doctors, and Care Workers. Manufacturing Robots Running off Humans? Should workers be concerned about the infiltration of robotic workers? While the US and Canada have lost more than 6 million jobs to overseas outsourcing, the majority of job losses in both countries was due to machines replacing humans. The facts, however, tell us that over the past two decades, inflation-adjusted U.S. manufacturing production has grown nearly 40%. While there may be fewer jobs, more is getting done. Manufacturing employees have better education, are better paid and produce more valuable products — including technology that allows them to be more productive. In the past few years, there have been millions of jobs remaining unfilled in the manufacturing sector. The aging workforce is not being replaced by younger workers. Youth are more interested in other work. There are other issues to consider as well: Robots are safer. They are reliable. They are more ethical than using exploited labor overseas. They’re incredibly cost-effective, with manufacturers seeing return on investment in 12 months or less. Robots allow manufacturers to focus on innovation. This creates new jobs that require and build a more educated, highly skilled workforce. So, will a robot take your job? Possibly. But, in return, workers of the future will likely find more meaningful work, for better pay. But there is also a distinct possibility that more white-collar jobs will be taken by robots with AI. Conclusion While many will continue to fear robots and AI for the damage they can do to the job market, when businesses are able to save money with cost effective machinery, they have more resources to higher more skilled workers. The robot revolution is inevitable. Humans in manual labor jobs need to prepare for adding new skills or starting a whole new career. Full article: https://www.iqsdirectory.com/resources/how-the-robot-revolution-affects-the-manufacturing-business/

Insulation Manufacturer Improves Its Tubing Range

Italian based global manufacturer, L’Isolante K-Flex, is pleased to announce that an improved version of their K-Flex® ST/SK product will be available from January 2019 following extensive development work to enhance its insulation capability. The new version of adhesive tubes will be available in diameters from 14 mm to 114 mm, and thicknesses from 9 mm to 40 mm, guaranteeing optimum insulation. The method in which the tube is now cut significantly increases its strength and durability. By using this enhanced product, customers will continue to benefit from saving on overall installation time and improved working conditions. BevEx is part of L’ISOLANTE K-FLEX Insulation Group and manufactures beverage dispense equipment with innovative insulated tubing products for the beverage industry worldwide, using the latest technology to meet the demands of major breweries and bottling companies. All products meet the EU Directive 2002/72EC for food contact applications and are manufactured to ISO9002 using industry approved materials with full traceability. It is based at Coalville in the East Midlands, supplying the European Beverage Market. Its management team has considerable experience in the manufacture and supply of dispense equipment to the global beverage industry. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

£1M Government Grant to Revolutionise Digital Medicines

A £1 million government grant has been awarded to Arcinova, a multi-service CRDO, for its £2 million Fill-Inova project. The grant will be used to develop a digital manufacturing platform to accelerate the production time of patient-specific medicines. The Fill-Inova Project aims to create a more responsive and economical method for producing complex formulations in smaller volumes. By employing digital technologies with automation and machine learning, Arcinova will be able to produce on-demand, specific therapies for small patient populations. UK Research and Innovation (UKRI) will provide £1 million as part of the Industrial Strategy Challenge Fund, a government initiative to raise productivity and earning power in the UK. The Fill-Inova Project will increase the UK’s capacity to manufacture small-molecule and high potency medicines, with patients set to benefit from accelerated access to targeted drug therapies. “It is fantastic news that our innovative platform for digital medicines manufacturing has been awarded funding by UKRI. The grant will accelerate our Fill-Inova Project by 18 months, allowing us to quickly address a pressing patient need,” commented Gareth Jenkins, CSO at Arcinova. The current manufacturing method for patient specific drug products involves a non-automated procedure with a production rate limited to 200 units per hour. The Fill-Inova project will utilise state-of-the-art robotics to increase production to 1000 units per hour, while maintaining the same level of operator labour. This novel robotic capsule handling system has been designed to provide Arcinova with an agile manufacturing procedure with traceable weight recordings for each individual capsule. “We are delighted to receive this substantial award. Adding digital manufacturing to our capabilities will help us further realise our vision of improving patient care through transformative technology and integrated solutions,” said Ian Shott, CEO and Chairman at Arcinova. The creation of this new manufacturing methodology will involve a partnership with 3P Innovation Limited and its patented, fully automated system for the precise dosing and filling of powders.

Make Your Manufacturing Operations More Eco-Friendly

The manufacturing industry is booming, but the increase in production and processes can certainly take their toll on the environment. Barry Crackett is a product designer at the industrial, agricultural, and municipal brushware company Brushtec. The brand is consistently working to make their processes greener, and here he will be sharing his top five tips for making your manufacturing operations more eco-friendly. With recent figures showing that the value of UK manufacturers’ product sales increased by 4.1% between 2016 and 2017, it’s clear that the sector is certainly thriving (Office of National Statistics). And, while that’s great news for all manufacturing and production businesses, this doesn’t come without an environmental impact Whether you manufacture chemicals, food, or anything else, your processes are bound to emit some harmful greenhouse gases, as well as use up a lot of energy. So, with this and the expansion of the industry in mind, it’s clear that we all need to be taking measures to make our processes more eco-friendly. Here, I will be sharing my top tips for reducing your environmental impact while still allowing your business to progress. Carry out an energy audit Before you begin making any changes, you should carry out an energy audit so you can see how much energy you’re using both overall and on each step of the manufacturing process to identify where you could be using less. These audits can be done by yourself or you can hire a professional to ensure you don’t miss any important observations. These usually include monitoring production lines, machinery, lighting, and anything else that is guilty of guzzling excess energy and harming the environment along the way. In some cases, you might even be legally obligated to carry out a survey — the government’s Energy Savings Opportunity Scheme makes it mandatory for UK companies that employ 250+ people, have an annual turnover of over £38,937,777, and an annual balance sheet totalling over £33,486,489. Once you’ve calculated your energy consumption and identified specific areas of overuse, you’ll then need to appoint a lead assessor within your team to carry out and review your energy audits, as well as complete an ESOS assessment — but, be aware that whoever you pick must be a member of an approved professional body register. Switch to energy-saving solutions Once you’ve carried out your energy audit and identified the problem areas of your processes, you can then begin implementing energy-saving solutions. As a switch to eco-friendly machinery and equipment may be costly, you can kick-start a change by making smaller, more basic changes. I recommend taking a look at your lightbulbs and seeing whether they can be switched for environmentally-friendly options like newer LED models. You could also improve your heating efficiency by updating your insulation and using draught excluders, as well as investing in smart thermostats that will turn themselves on and off to help you conserve energy. Recycle and reuse materials While it might be hazardous to reuse certain items, such as chemical containers, there are bound to be plenty of other things you can recycle within the workplace. The likes of packaging your supplier sends things in, as well as empty bottles and scrap paper can all be recycled to reduce the amount of waste your company sends to landfill. Not only will this ensure you’re operating more responsibly, but becoming more eco-friendly can also help you to target more environmentally-conscious companies and customers, which should welcome in more business. You should also be looking at your processes and reviewing these to see if there is anything you can omit or lessen in your manufacturing processes. This could include using recycled plastics, paper, or glass for your packaging and in the manufacturing of your products. It might also be a good idea to invest in a recycling machine that will allow you to deal with these things on site — cutting down on the need for more polluting lorries to take your recycling away will help to minimise your company’s carbon footprint. Save water Many of us take our water supply for granted, meaning it can often be used in excess. But you should be monitoring the way you treat, use, and dispose of water to save you money and lessen your environmental impact. Calling in a professional to carry out a water audit can show you where you are using most of your water and how you can save on this. They will come up with effective strategies that you can follow to reduce the amount of water you use, which will be kinder to the environment as well as shaving plenty off your water bill: it’s a win-win! Partner with eco-friendly companies Many manufacturing companies will rely on other businesses in one way or another but, when your supplier has the same eco-friendly visions and goals as you, it’s bound to have a positive effect on your overall environmental impact. In some cases, this may require you to change suppliers to find ones that are producing eco-friendly solutions and focusing on promoting sustainability in their own processes. Many power suppliers will also offer green energy packs that will ensure you’re making the most of renewable energy and protecting the planet without minimising productivity or efficiency within your manufacturing processes. We all want our businesses to thrive, but this doesn’t have to be at the cost of our planet. With my top five tips and some initiative, you can take steps to reduce your environmental impact and still keep your manufacturing business running smoothly.

Food and Drink Market to Go Premium

A new generation of modern convenience food and drink is emerging, said market intelligence agency Mintel. Manufacturers are responding to rising healthy eating priorities, quests for foodie-inspired flavours, interests in personalisation and competition from speedy delivery services. A new wave of shortcuts will also be available, including the expansion of individual meal kits, foodservice-inspired packaged beverages, and a new generation of prepared meals, sides, and sauces that emulate the flavours and formats of restaurant meals. Mintel predicts interest in premium convenience will not be limited to dinnertime, creating opportunities for every meal, snack, and beverage break. “We predict the rising segment of consumers who are often on-the-go, yet want to spend more time at home will increase demand for upscale, ‘speed scratch’ solutions and restaurant-quality, ready-to-consume products,” said Jenny Zegler, associate director at Mintel Food and Drink. “As meal kits and foodservice-inspired beverages lead the way, there will also be more opportunities for brands to develop healthy, flavourful, customisable, and quick premium convenience products for breakfast, lunch, dinner, snacks and dessert occasions,” she continued. Another trend identified by Mintel will build on the current focus on wellness and transition into solutions for healthy ageing. Mintel believes more food and drink can be formulated to address concerns from people of all ages about bone, joint, brain and eye health as well as other age-related health concerns. “Expect to also see food and drink manufacturers look to the beauty and personal care industry for inspiration for healthy ageing product development. More food and drink will address longevity-related health concerns, be marketed with positive language that rejects terms like ‘anti-ageing’ for its negative connotations, and appeal across ages,” Jenny added. The final trend Mintel identified for next year regards sustainability. Sustainability efforts will include not only improving access to recycling, but incentivising consumers to recycle packaging and offering upcycled goods. Bank. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

FER Conference Dominated by Technology

The annual conference and AGM of The Federation of Engine Re-manufacturers (FER) took place in October 2018 at the Park Inn, Radisson, York and it was opened by the FER’s new operations manager, Owen Laurenson, who outlined key objectives for the federation in 2019. “The conference was very engaging with new engine technology and electric powered vehicles dominating a lot of the discussions. The enthusiasm from our members is key to the Federation’s continued future development and despite the numerous threats facing our Federation, FER members continue to drive engine remanufacturing and remain at the forefront of the aftermarket industry,” commented Owen Laurenson. FER now has a new website and wants to ensure its members that it will continue to maintain their high standards of service delivery to the motoring public and trade customers, whilst diversifying their services in line with technology changes going forward. Following Owen’s speech was engine parts supplier Elring that highlighted the differences in product technology from the past, present and future. The presentation, by Mark Ventre and Mike Knowles emphasised the market shift to vehicle electronic components which are now out-selling hard parts in the automotive aftermarket. Rotating electrics supplier AutoElectro’s managing director Tony Bhogal then delivered a comprehensive overview of their business and looked at why accurate fault diagnosis is not only key to effective first-time repairs, but also allows the business to focus on ensuring a comprehensive stock of parts to meet customer demands. Bhogal also reiterated that customers were ‘browsing online’ much more to check product availability, ordering parts and arranging warranty returns. In both presentations, new engine and technology, the potential effects of Brexit and the increasing development of electric powered vehicles dominating the discussions. During the federation’s AGM, David Eszenyi of Ivor Searle was voted in as the new president of the FER with John Dormer as Vice President and Adrian Wilkes of Gosnay’s voted in to continue as treasurer for the next 12 months. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News