Results Indicate Hope Between Manufacturing Companies

The results of a conducted investigation of 461 manufacturing companies based around the United Kingdom have shown that a wave of optimism is spreading across the country in the manufacturing sector. The CBI Industrial Trends Survey seems to have found that the amount of order rates that have been made to manufacturing companies has actually risen at breakneck speed from July 2014. Similarly, the amount of requests for products has gone up very speedily, as has the rate of methods of production in order to meet these increased requests for manufacturing. These details therefore seem to indicate that manufacturers are feeling positive about the future of their businesses, despite the shock and unrest on the markets as a result of the EU referendum. A great deal of firms around the country have in fact felt that the popularity and demand is so great that they are seeking plans to have greater storage space and facilities so as to manage their increased activity even more. Many of the companies that were surveyed were also reported to have underperformed the least ever since the year 2015, suggesting that companies are consistently delivering and matching their target objectives. On the other hand, a large number of those interviewed by CBI reported their thoughts on the evident lack in skilled workers around the country. For 25 per cent of those that were surveyed, this is a very pressing worry for them that they will need to investigate in order to preserve the future of themselves and the manufacturing industry in this country. Not since 1989 have individuals in the manufacturing industry voiced so many concerns about this frightening issue, yet there is hope that now that the issue has been raised, companies will do more to ensure that their workforce is more skilled for the work that needs to be done. Through various plans, possible intern- and apprenticeships, the manufacturing industry can work together to resolve this issue.

What Does A ‘Hard’ Brexit Mean for UK Manufacturing?

Brexit means Brexit and, following the Prime Ministerâs speech in late January where she set out what this will entail, Brexit means a âhardâ Brexit. While the Supreme Court has now ruled that Westminster will need to approve the Governmentâs Brexit plans, the intention of leaving the Single Market could have direct implications for the UK Manufacturing sector, especially those companies which currently export to other EU markets. UK manufacturing is currently robust, with the sector ranked 11th in the world, responsible for 54 per cent of Britainâs exports and 2.6 million jobs. Following the referendum weâve seen a significant fall in the Pound against key currencies like the Euro and US Dollar which has played havoc with the markets. The British manufacturing sector has, however, dealt with this fallout amid waves of growth speculation and revised forecasts, not to mention this new found weakness in the currency. The sector performed well in the second half of 2016, with a number of indicators showing growth across many aspects of UK manufacturing. While this has been positive news, UK economic growth in 2017 is expected to slow. The manufacturersâ organisation EEF has stated that only 23 per cent suggesting that opportunities will outstrip risks. The Poundâs exchange rate has been deemed largely responsible for the upswing in manufacturing as overseas buyers take advantage of the weaker currency, but itâs brought with it another problem â cost. Manufacturers have voiced concerns about Brexit talks dragging the pound down further and prolonging a period of profit pressure as import prices increase. Following the Brexit vote, the Confederation of British Industry (CBI) noted that although the weaker exchange rate may have boosted overseas purchases, domestic orders had been dented. Likewise, as Sterling begins to eventually ramp up import costs and businesses have their profit margins squeezed, consumers are likely to witness price increases which could potentially cause a decline in domestic spend. Looking forward, the prospect of a âhardâ Brexit creates some exciting opportunities as well as real threats for UK manufacturing. In the longer term, if the UK Government is successful in securing structured trade deals with key countries outside the EU, British manufacturing businesses could thrive in a new and favourable global trading landscape. This optimistic view is supported by some positive developments with plans to launch some high-end designed products including specialty bicycles in the UK and the commitment from companies such as Rolls-Royce to continue their manufacturing in the UK. Indeed, While the potential of securing positive trade deals outside the EU could provide some great opportunities for the sector, the concern is that if this process is dragged out it could affect confidence and lead to UK manufacturers moving operations overseas. These global trade negotiations will be especially critical for the automotive manufacturing industry as the UK exports over 1.2 million cars every year and half of those make their way to the EU. Although the weak Pound may be contributing towards an upswing in UK-based car manufacturing now, some industry experts are concerned that investments in the latest technical advances such as autonomous and electric vehicles may be impacted post Brexit. As we enter 2017, thereâs likely to be a lot of currency fluctuations as markets adjust to new developments. It is therefore vital that exporting manufacturing businesses in Britain put in place a strategy to mitigate this uncertainty and the possible impact on revenues. The trade deals with the EU are likely to cause an elevated level of volatility with the Pound as it will determine the price of manufactured products for British people, and also impact on the profit margins of businesses. Manufacturing has stood strong in the face of Brexit but the negotiations which will follow the triggering of Article 50 could very likely bring more uncertainty. While the sector could see some short term benefit, especially through further fluctuations in the Pound, its longer term prospects will be determined by the success of Government negotiations with both the EU and other potential global trading partners. Greg Smith, Head of Trading at foreign exchange specialists Global Reach Partners Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Historic Hospital Bed Maker Snapped up by US Firm

Historic Hospital Bed Maker Snapped up by US Firm : A designer and manufacturer of hospital beds which can trace its roots back 130 years has been acquired by a private equity-backed US counterpart. The £26m-turnover healthcare equipment specialist Sidhil, which is headquartered in Halifax, has been acquired by Drive DeVilbiss Healthcare in a deal supported by Clearwater International. The business makes hospital and home healthcare beds, furniture and accessories, serving national and international private and public healthcare markets. Peter Siddall, chairman of Sidhil Group said: “I’m very proud of what Sidhil has achieved as a family-run business. This acquisition creates fresh opportunities for the development of new products and services designed around the changing needs of the healthcare market.” Headquartered in New York, Drive DeVilbiss Healthcare manufactures a line of medical aids including mobility products, sleep and respiratory products, beds, bariatric products and wheelchairs. The business has recently undergone a recapitalisation with US private equity house Clayton Dubilier & Rice to fund continued international growth. Richard McGleenan, managing director of Drive DeVilbiss Healthcare, added: “Sidhil has established a leading reputation for providing high quality, innovative products and services to their customers. “With worldwide distribution and over 130 years of healthcare manufacturing in the UK, this is a key acquisition for Drive DeVilbiss Healthcare elevating us to market leader in the provision of beds and support surfaces into the UK healthcare sectors and also expanding our UK manufacturing footprint.” Interested in this article? Read more at Insider Media Limited. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Carver Group Expands with Canadian Acquisition

Carver Group, the family-owned manufacturing business, has acquired Canadian-based Applied Comfort Solutions to strengthen its product portfolio and open routes to the US market. The acquisition marks the first moves of the family businessâ ambitious growth plans to double in size over the next five years through organic growth and carefully selected acquisitions. Carver Group, which encompasses international brands Biddle, Thermoscreens and Widney, has over 240 years of rich heritage, with roots firmly in the Black Country. The acquisition, which completed on Monday 12 December for an undisclosed sum, will see the business and its workforce increase by around 25 per cent as the management team continues to invest significantly in the future of the firm. Applied Comfort Solutions has an established sales and distribution network across the US and focuses largely on the design and manufacture of niche Package Thermal Air Conditioners (PTACs). Although providing routes to market in the USA, the Midlands-based centres will benefit from an increased and varied product manufacturing range. Aidan Killeen, group ceo at Carver Group, said: Although the business has been in operation for over 200 years, our ambition to grow and develop has never been stronger. Like many businesses we have had to evolve with the current market and there are huge growth opportunities in the US that we are well-equipped to take advantage of. With the US being one of the largest markets in the world for innovative HVAC solutions, ensures that our existing product portfolio as well as the distribution base that the acquisition brings will further strengthen the firmâs international and regional operation. Shakespeare Martineauâs team of advisers supported Aidan Killeen and Group Financial Director, Stuart Fyfe, on the transaction and helped to smoothly navigate the Canadian legal system. Article taken from http://www.acr-news.com/carver-group-expands-with-canadian-acquisition

£60m Boost to Fund Six New Research Hubs

Universities and science minister Jo Johnson has given £60 million to fund six new research hubs to boost innovation and improve manufacturing techniques in the UK. The Engineering and Physical Sciences Research Council will provide the finances for the scheme, with the hubs led by the universities of Sheffield, Huddersfield, Nottingham, Cardiff, Strathclyde and University College, London. These will pool expertise from 11 other universities and 200 partners drawn from industry and academia. They will focus on areas such as powder-based manufacturing processes, biological medicine and 3-D printing. Johnson commented: Developing new innovative manufacturing techniques will help UK industry create new products, explore more business opportunities and ensure the UK becomes more competitive and productive. This investment will lay the foundations to allow industry and our world-leading universities to thrive for years to come and is exactly the type of project that our upcoming Industrial Strategy will look to support. Professor Philip Nelson, EPSRCâs chief executive said that some hubs will develop on earlier centres for innovative manufacturing while others, such as the Sheffield university hub, would be new ventures. He added: EPSRC is pleased to be at the forefront of the drive to keep the UK a prosperous and productive nation. One of the universities involved in the scheme, The University of Huddersfield, is set to launch a £30 million UK Manufacturing Research Centre. The Future Metrology Hub will be situated in the Universityâs Centre for Precision Technologies, which houses a team of researchers in precision engineering and metrology. Researchers at the universities of Sheffield, Loughborough and Bath will provide complementary expertise and support, as will the National Physical Laboratory (NPL) from its bases at Teddington and Huddersfield. The Hub is set to address major, long-term challenges facing UK manufacturing industries. A large team of industrial partners, including companies from a wide variety of industrial sectors, will also provide funding and support to the Hub.

Former Swindon Triumph Site Sold to Logistics Firm

The former Triumph manufacturing and warehouse site on Swindonâs Groundwell Industrial Estate is to be redeveloped, following its acquisition by logistics group Howard Tenens. The Stroud-based company bought the facility with support from property consultancies Savills and Whitmarsh Lockhart for an undisclosed sum. Located on a 7.2 acre site, self-contained facility is comprised of a 117,920 sq ft warehouse with 44,793 sq ft of mezzanine space and a two storey administration office building at the front. Built in 1980, the site benefits from two road entrances: one from Arkwright Road as a main entrance and another at the rear for commercial vehicle access off Crompton Road. Lingerie firm Triumph closed the distribution centre in 2014, resulting in a loss of 70 jobs. Simon Emms, property director at Howard Tenens, said: Groundwell Industrial Estate is a fantastic addition to our portfolio and offers plenty of scope for reconfiguration and refurbishment of the property. We intend to commence the refurbishment works shortly to provide a flexible and modern warehouse facility, with the works due to be completed at the end of Q2 2017. This acquisition bolsters our offering in Swindon where we currently have extremely high occupancy levels at our main Europa Industrial Park. The strategic location, with fantastic road access and wider links to the south and industrial midlands, together with high occupier demand should make this an exciting proposition in the market. Rob Cleeves, director in the industrial team in Bristol, said: We are pleased to be involved in this exciting project moving forward. The site has been well maintained and comes with the added benefit of expansion land to the side, which can be developed with the correct planning permission. With the lack of available property in the market we are sure that the property will be attractive to a wide range of occupiers. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Thomas Tunnock Commissions Fourth Manufacturing Plant

Thomas Tunnock has commissioned a fourth teacake manufacturing plant to meet growing demand for its products as underlying profits at the business grew 14.5 per cent to £7.1m on sales of £53 million. In addition to the new plant, further investment has also been made at the biscuit makerâs Uddingston base, with planning permission granted for a factory extension to meet growing demand. The results to the year ending February 29 cover the period, in January this year, when Tunnock became embroiled in controversy when it ran a campaign in England calling itself the Great British Teacake to reflect the success of the Great British Bake Off television programme. The move was criticised by Scottish nationalists who called for a boycott of the products. This received short shrift from Boyd Tunnock, the octogenarian head of the firm, who noted: We could have said Scottish but youâre then promoting Scotland. Weâre British. The family-owned business â which produces caramel wafers and snowballs in addition to its teacakes said the sales boost reflected steady growth in our markets. In accounts newly filed at Companies House, it was revealed that underlying profits were up in spite of a 0.5 per cent reduction in pre-tax profits relating to a £1m exceptional gain booked last year. Sales per employee fell to £104,000 from £108,000. Thomas Tunnock sales in the UK grew two per cent to £44m while the companyâs export sales returned to growth. Overseas sales saw a 12.5 per cent uplift to £9m, returning to the level enjoyed in 2014. Thomas Tunnock exports to more than 30 countries, and is noted for its popularity in the Middle East. It also enjoys a strong following in North America and Australia, and has more recently been pushed into European markets. In a statement, the company said: Following continued investment, a fourth teacake manufacturing plant has just been commissioned and with planning permission recently received for a factory extension, the company continues to invest in the local community and beyond.

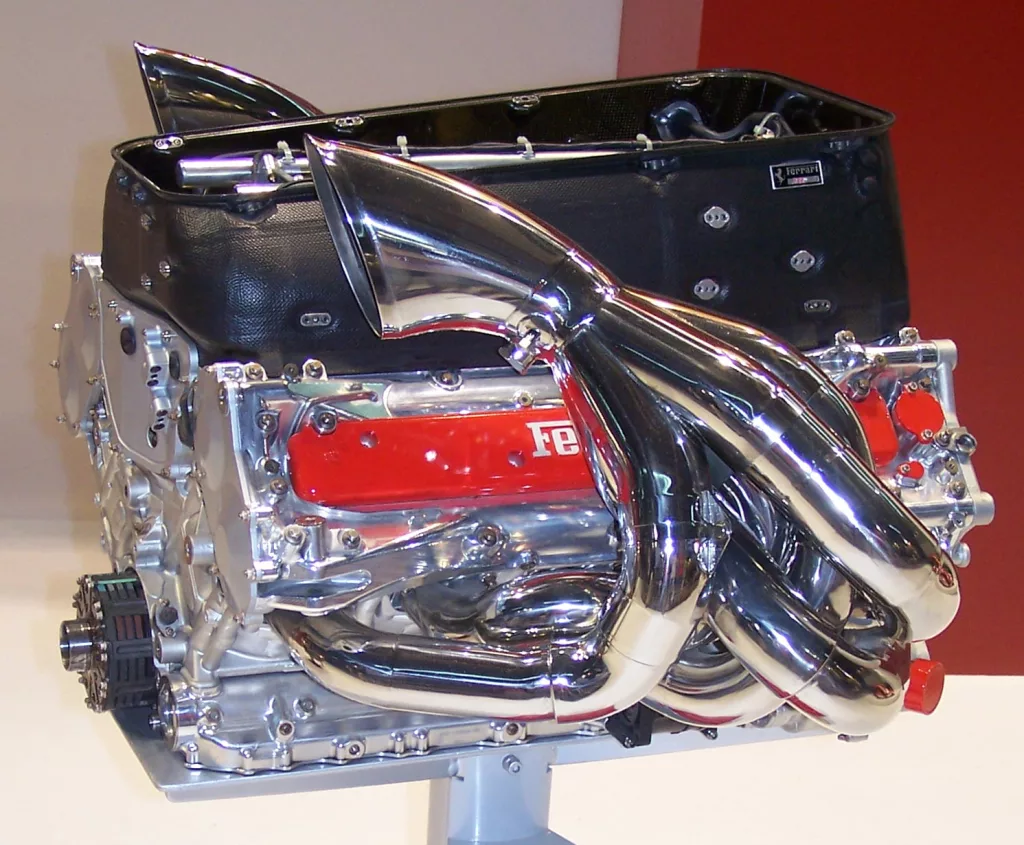

Formaplex Expands Manufacturing Capabilities with 120,000 Sq Ft Facility

Hampshire-based engineering firm, Formaplex, which supplies tooling and lightweight components to the premium automotive, F1 and motorsport industries, has expanded with the opening of a new 120,000 sq ft facility. The company, which has been shortlisted in the Large Manufacturing Company of the Year category at the upcoming Insider Made in the South East Awards, said Voyager Park will increase production space by 80% to support the businessâ future growth. Altogether, the firmâs total footprint now spans 270,000 sq ft across four sites in Horndean, Portsmouth, Cosham and Havant. The new site will accommodate a total of 15 injection mould presses to support the rising demands of lightweight moulded components, along with in-house finishing, assembly and metrology departments. It has created around 100 new job opportunities. Mike Bryant, Formaplex Chief Executive, commented: “We have experienced steady growth over the last five years, resulting in our current sites working at full capacity. This growth has been positively impacted by confidence in the automotive sector and increased international demand for UK premium car brands. “We are currently producing 600 injection mould tools and moulding approximately three million thermoplastic components per year, predominantly for the automotive industry. Our new premises will ensure we have the additional capacity to continue to provide our services and world class products to our blue-chip customer base.” Formaplex was established in July 2001 and was acquired in a management buyout supported by private equity company DunedIn in 2007. Earlier in the year, Formaplex unveiled a new 11,000 sq metre factory on its Cosham site, near Portsmouth. The new technical centre âVoyager Parkâ is set to increase production space by 80% to support future growth of the business. The new £6 million facility will accommodate a total of 15 injection moulding machines, for producing lightweight-moulded components, together with in-house finishing, assembly and metrology departments. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Concepta to Launch New Doncaster Manufacturing Facility

AIM-listed healthcare firm Concepta is set to launch a new manufacturing base in Doncaster. Backed by Finance Yorkshire, the business has signed a 10 year lease on the site at Bullrush Grove Business Park where it will employ eight full-time members of staff. The newly built 6,000 sq. ft. premises will be used to make lateral flow test strips for the firmâs MyLotus product for unexplained infertility. The product will be launched later in the year in China later before being made available in the UK and Europe next year. Before being listed on AIM, Concepta received a total investment of £2.3 million from Finance Yorkshireâs Seedcorn Fund along with Diagnostic Capital and the Angel Co Fund. Finance Yorkshire Chief Executive, Alex McWhirter, commented: Conceptaâs strong growth to date demonstrates Finance Yorkshireâs successful track record for investing in early stage innovative technology companies. Our investment has proved pivotal in enabling Concepta to realise the potential of its products to the point now where it is enjoying expansion in the Yorkshire region. CEO of Concepta, Erik Henau, said: We are pleased to have signed the lease on this excellent location for our UK manufacturing operations. Concepta has a commitment to Yorkshire through one of the earliest backers of our business: Finance Yorkshire. The securing of this new facility is essential to our companyâs continued growth. Concepta was founded three years ago and makes products targeted at the personalised mobile health market with a primary focus on womenâs fertility and specifically unexplained infertility. The new Doncaster site already has office space fitted and the business is now establishing its manufacturing, warehousing and quality control areas. The premises will be fully operational by early next year and has the capacity for further expansion.

Welsh Government Pledges £20m Into Advanced Manufacturing & Research Institute

The Welsh government has pledged £20 million to establish an Advanced Manufacturing & Research Institute in the country. The funding will help it secure a key role in the design and development of future aircraft wing technology. The institute has been developed by the Deeside Enterprise Zone Advisory Board, AMRC Sheffield, Swansea University, and Coleg Cambria in conjunction with SMEs and large companies. It will have a primary focus on advanced manufacturing sectors including aerospace, automotive, nuclear and food. The facility will target collaborative R&D, advanced manufacturing techniques and production processes, training needs and skills across industry. The institute will operate as a single entity, split between a proposed 4,500sq m R&D site in Broughton and a 1,500sq m networking, training, business development and advice facility situated near to the Deeside Industrial Park. Both centres will be open access and outward looking, actively seeking collaborative partnerships with industry and academia partners locally and internationally. Ken Skates, Economy Secretary, commented: The institute will deliver game-changing support to key manufacturing companies as well as multi-sector supply chain companies and the broader SMEs economy. It is geared to increase productivity, commercialisation, innovation and skills development to ensure a thriving competitive industry base that will be a catalyst for growth and jobs across the supply chain in Deeside, North Wales, the Northern Powerhouse and further afield. The in principal funding from the Welsh government will support an initial £10 million investment from project partners to develop the institute. Airbus has confirmed that it will be the first tenant for the centre. Working with AMRC Sheffield as the key partner it involves the R&D test phase for new wing technology, called Wing of the Future which includes the prototype and delivery of design, engineering and a wing demonstrator at Broughton. The R&D project will support Broughtonâs ability to secure the manufacture of these new wings in the future, which will help towards safeguarding thousands of jobs up to 2030.