Beckhoff XTS System Revolutionises Motion in Food and Beverage Manufacturing

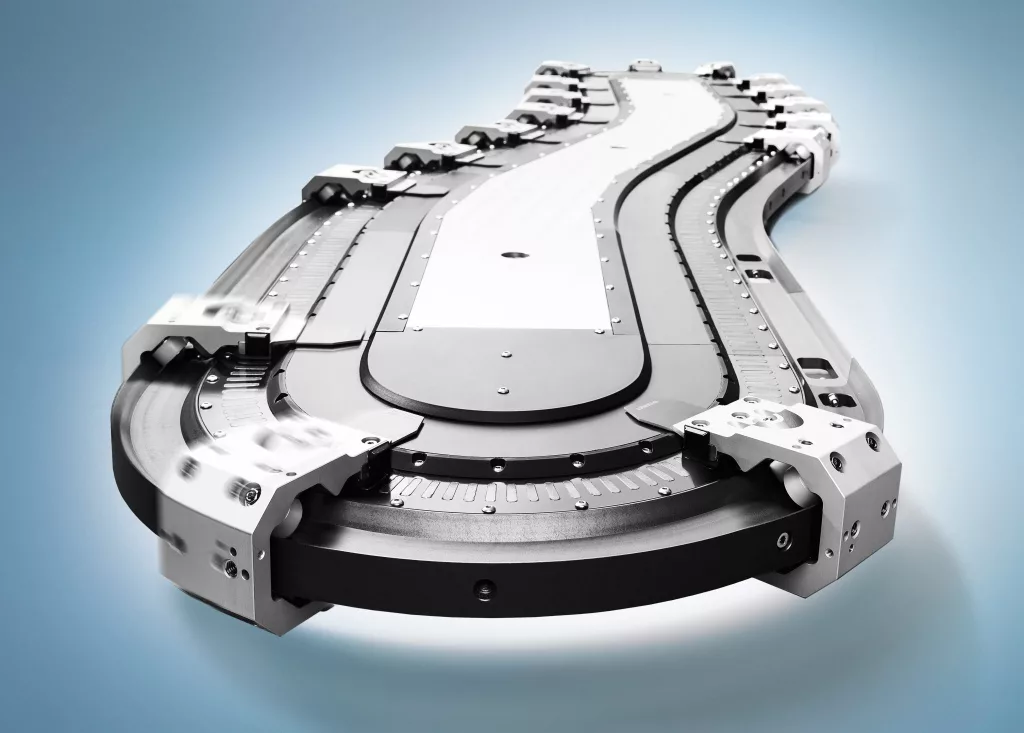

Beckhoff XTS System Revolutionises Motion in Food and Beverage Manufacturing : According the latest United Nations (UN) data, two thirds of the world’s countries expect 50 per cent increase in population between 2019 and 2050. Manufacturers in the food and beverage industry are under pressure to satisfy increasing demand, and ensure that products are safe and comply with numerous regulatory guidelines. For food manufacturers that are willing to innovate, Stephen Hayes, managing director of industrial PC provider Beckhoff Automation UK, explains how a revolutionary new transport system can help. Increasing productivity and safeguarding consumers’ health are the two main challenges for food and beverage manufacturers. On the one hand, plant managers are expected to speed-up production and diversify their offerings, in order to keep up with increasing demand from more informed consumers. On the other, they must comply with a sector that is among the most strictly-regulated when it comes to hygiene standards. Food safety essentially relies on the control of contamination. In this sense, transport systems used in food processing are a central concern for the food industry, as micro-organisms can easily accumulate in the different components of a conveyor. If this happens, consumers’ health is at risk and so is the manufacturer’s reputation. A revolutionary movement Thanks to its innovative eXtended Transport System (XTS), Beckhoff’s Automation segment has succeeded in turning food manufacturers’ biggest concerns into opportunities. Specifically, to speed up production while improving cleanability. Like any truly-innovative idea, the XTS system is based on a simple, yet ground-breaking concept. Or, in this case, two concepts: first, the possibility for every mover on the track to glide independently; plus the combination of rotary and linear elements to create a customisable track. In fact, Beckhoff’s XTS transport system combines the benefits of two well-known drive principles, linear and rotary, into a single mechatronic system. This has never been done before and allows manufacturers to create the perfect geometry for their application, no matter how complex. There are no length restrictions for the entire path and the number of movers can also be customised. In other words, the system is limited only by the available computing power of the industrial PC. On this track, movers can be positioned in different parts of the belt and travel independently; each with its own speed, acceleration and motion pattern. Alternatively, movers be combined into couples or clusters in order to create hoops that travel together at an established speed. Additionally, the XTS can be operated in any installation position, so it can be applied with maximum flexibility to match the specific needs of the production line. More hygiene with improved cleanability Beckhoff’s XTS is also available in the Hygienic version, a stainless steel model that combines the benefits of this revolutionary transport system, with improved cleanability and resistance to harsh detergents and disinfectant. The XTS Hygienic is therefore perfect for industries where frequent washdowns are mandatory, such as the food processing industry or the pharmaceutical sector. Severe rules for the hygienic design of transport systems have been established by the European Hygienic Engineering & Design Group (EHEDG). The XTS is EHEDG compliant and meets the requirements for system certification according to EL Class I AUX. It has a protection rating of IP69K and can therefore cope with surfactants, acidic and alkaline cleaning agents as well as with different types of alcohol, disinfectants and even hydrogen peroxide. The stainless steel body of the transport system ensures a high resistance to delamination, while the absence of edges or undercuts prevents soil accumulation and facilitates cleaning. Additionally, all components of the Hygienic XTS are sealed at the joints with a high-quality elastic material that enables high-pressure washdowns. Thanks to these characteristics and its innovative approach to motion, the Hygienic version of Beckhoff’s XTS has been shortlisted for the Food Processing Awards 2019 in the category, ‘Process & Packaging Solution or Process’. Unprecedented challenges call for unprecedented solutions. With the XTS Hygienic, manufacturers can optimise production and ensure that manufactured foods comply with the highest hygienic standards. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Inside the Bombardier Global 7500 Aircraft

Inside the Bombardier Global 7500 Aircraft : International firms heavily rely on business jets – and it’s fairly obvious why. Aboard a premium aircraft, company representatives can prepare for crucial events and meetings in complete comfort. With the upcoming release of the Global 7500 aircraft, worldwide transport manufacturer Bombardier promises a business flight experience like no other. Here, we explore what the jet has to offer… Behind Bombardier Bombardier has stood at the forefront of jet construction for over thirty years. However, its story begins way back in 1937, with the creation of the first “snow vehicle”. Built to ease road travel during Québec’s bitterly cold winters, it soon underwent huge development to become a leading snow motor across the world. In 1970, the company ventured into new travel territory, offering premium railway services for the first time ever. It wasn’t long until the firm took to the skies, of course. Since then, it has garnered a wealth of loyal customers, thanks to its high-quality facilities – and it looks set to advance the industry even further… Record-breaking speed Speed is obviously essential when it comes to long journeys, especially if you’re travelling on business. You’ll want to arrive at your destination with enough time to relax before the big meeting or event, after all. Bombardier clearly know the value of using a high, safe speed in the air, as the Global 7500 illustrates. The Jet has already set a speed record for the fastest journey between New York and L.A, which was completed in just under four hours. This is particularly impressive when you consider that a typical flight between the two stops takes over six hours! In addition to speed, the aircraft also boasts a record for the longest flight ever taken between Sydney and Detroit, Michigan. Perks for passengers Speed isn’t the only perk that the Global 7500 offers – it’s designed for comfort and performance in equal amounts. And so, it’s ideal for business travellers. The only business aircraft with four living spaces, it provides an open area for passengers to roam, relax and prepare for their big work event. Not to mention, the jet includes a permanent private stateroom suite, so that travellers can fly in complete luxury. Serving Michelin-inspired cuisine, it’s the ultimate in business aviation. Given its emphasis on customer care and quality, it’s unsurprising that VistaJet will be the first aviation firm to offer flights on the Global 7500 commercially. The company has long been renowned for its excellent services, from its empty leg flights to its wine program. The Global 7500 marks a new era for luxury air travel. With so many technological advances ahead, what does the future hold for this esteemed industry? Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

UK Industry Still Skeptical About Deployment of Robots

A leading robotics industry expert believes that UK industry remains skeptical about the deployment of robots, and that what is needed is a more positive and realistic attitude. Dr Susanne Bieller, General Secretary of the International Federation of Robotics, voiced her thoughts ahead of Bot-Talks, an open event to be held in Bristol on Wednesday 20th November for SMEs, and organised by Bristol robotics online platform, Bot-Hive. Dr Bieller, who is travelling from her base in Frankfurt, Germany to talk at Bot-Talks, said in the build-up to the event: “Overall, the business world is accepting robotics and automation very well. If you are active on a global scale and want to remain competitive, there is no alternative to automation for most businesses – the question rather is where to start and which processes to automate first. “The issue we are facing here in Europe, and I think the UK is not an exception, is the public perception of robotics and, related to that, a certain scepticism against the deployment of robots. There is a huge difference among the public opinion across Europe. It certainly has an impact how trade unions are supporting the automation process, and also how the media are influencing the debate. “It is quite interesting to see that this debate basically is unknown in countries like Japan and China, where they see the basic need to automate in order to compensate the lack of qualified labour. “I would love to see a more positive and realistic attitude toward robots. Neither fears nor exaggerated expectation do really help in the further expansion of robotics and automation.” Some of Europe’s leading experts on robotics will descend on The Watershed, on 20th November as Bot-Hive holds its first ever Bot-Talks (tickets available here). Created to provide SMEs with a best-in-class overview of robotics and automation, Bot-Talks consists of presentations from leading industry experts, a panel discussion and a networking hall filled with robot demonstrations. Bot-Hive CEO Jacques Bonfrer will open an afternoon of talks, with the following line-up: Mike Wilson, Chairman of British Association of Robotics & Automation, on the state of UK robotics; Kate Hyslop, Head of Marketing of Automata, on democratising robotics; Jim Davison, Regional Director of Make UK on robotics in manufacturing; Professor Tony Pipe, Deputy Director of the Bristol Robotics Laboratory, on autonomous vehicles; and, Karl Foster, Head of Technology at Blake Morgan, on robotics and ethics. This will be followed by a panel discussion between: Farid Dailami, Associate Professor of the Research Innovation Facility Bristol; Dominic Keen, CEO of Britbots; Dr Susanne Bieller, General Secretary of the International Federation of Robotics; Paul Grantham, Manufacturing Lead at Natwest; and Ashu Sharma, Robotics Expert, PwC Consulting. Bot-Hive CEO Jacques Bonfrer said: “This is a superb opportunity to hear some of the leading lights in the robotics sector talk about the state of play as regards UK industry and automation, where we currently are and what is coming up in the future. UK industry has to automate in order to become competitive within the global market and SMEs need someone to look to for guidance and leadership in these difficult times. I hope that Bot-Talks will play a part in this process.” Bot-Hive is a startup funded by Britbots and the Startup Funding Club, and based in The Robotics Laboratory, part of The University of the West of England. It is on a mission to help UK industry with its productivity problems. Bot-Talks takes place on Wednesday 20th November at The Watershed, 1 Canon’s Road, Harbourside, Bristol, BS1 5TX. It starts between 1.30pm and 1.45pm, with the conference taking place between 2pm-5pm, and networking and demonstrations between 5.30pm and 8pm. SMEs and other interested parties are welcome to attend the event and should register here. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

UK Trade Volumes Fall But Number of Manufacturers Exporting Rises

UK exports fell in Q3 amid a global slowdown in economic growth and rising international trade tensions, according to the latest Lloyds Bank International Trade Index, compiled in partnership with IHS Markit. Despite the challenging environment, more than eight in 10 (81 per cent) manufacturers surveyed said they had exported between July and September, the second-highest percentage since 2005. Manufacturers were helped by international supply chain efficiency hitting a 10-year high, as slowing global economic growth and the surplus inventory from stockpiling seen between January and March led to fewer bottlenecks and shorter delivery lead times from suppliers. Nine out of the UK’s 10 largest trading partners posted economic growth in Q3, with the rate of growth in France and Italy increasing. However, slower growth in markets such as Germany, Ireland, the USA and China all contributed to a fall in manufacturing exports overall. The International Trade Index posted a reading of 46.5 for new manufacturing export orders in Q3, down from 46.9 in the second quarter and the lowest since Q2 2012. A reading of above 50 indicates growth, while one below 50 signifies a decrease. Meanwhile, the UK automotive industry posted its weakest quarter for new exports in a decade between July and September, with respondents citing a sharp fall in European production levels and a global shift in investment towards electric vehicles. The fall in manufacturing exports was partly offset by increased overseas sales of chemicals, including pharmaceuticals, and luxury and sporting goods. Gwynne Master, managing director and global head of trade for Lloyds Bank Global Transaction Banking, said: “Our analysis underlines how the fortunes of UK exporters are affected by a complex range of factors extending well beyond our borders. “A slowdown in global economic growth and trade tensions are undoubtably making the environment for exporters challenging. There are, however, bright spots and it’s incredibly encouraging to see such a high number of UK manufacturers continuing to take advantage of new opportunities, pockets of international growth, and greater supply chain efficiency. “With a shifting outlook for exporters we see firms revising strategies that support their individual overseas trade objectives. Help can come in the form of financial solutions that mitigate the risk of trading in new markets, enhance working capital, or tools that enable exporters to better understand the best market for their products or services.” Financial services stabilise UK services exports According to IHS Markit data, new overseas sales of services fell for the fourth consecutive quarter in Q3, but at a slower rate than in Q1 and Q2 2019. The UK services index posted a reading of 49.6, up one point on the second quarter of this year but still slightly below the 50 mark that signals growth. The uptick was driven by UK financial services, which rebounded after four consecutive quarters of decline to become the only services subsector to register export growth in Q3. Financial services’ growth offset a fall in transport and communication services exports, which had previously grown during Q2 due to EU stockpiling. Gwynne Master added: “Our findings for transport and communications services firms show how fluctuating levels of inventory build-up in Europe and UK have impacted UK companies. “Between April and June, it looked as though UK firms were dialling back efforts to stockpile. In Q3, this has reversed, with PMI data showing higher inventory levels. While the reasons for building up inventory in this way are several, it has an inevitable negative impact on working capital. “Working closely with businesses to manage their working capital is a key component of our commitment to helping Britain prosper. By mitigating risk and managing working capital effectively, UK exporters can ensure they have the security and liquidity to navigate a fast-moving international trading landscape and take advantage of new opportunities at home and abroad.”

Manufacturing Businesses Some of the Least Prepared for Brexit deadline

Almost two in three UK businesses (63%) say they will not be ready for Brexit by 31 October – and 26% say they need a further 6-12 months to get their company Brexit-ready – according to new research by ThoughtWorks, the global software consultancy, to find out about the manufacturing sector. The national survey asked 1,026 business leaders how long it would take their business to adapt to the key regulatory, economic and data issues that will come as a result of Brexit. There was little variation between a hard or soft Brexit on business readiness (37% for both scenarios). Only 14% of business said they were already fully prepared for Brexit – and whilst this rises to 37% being ready by 31 October – the majority are calling for more time, with 9% of respondents saying they will never be ready. Brexit readiness by sector Businesses in the construction sector were those most likely to say they would be ready for the impact of Brexit by the end of October – whereas those in manufacturing and the education sectors were least likely to be fully prepared. Businesses in retail (31%), health (29%) manufacturing (29%) were most likely to say they would need a further 6-12 months to adapt to the key regulatory, economic and data issues that they believe will come as a result of Brexit. How long businesses need to adapt to the key regulatory, economic and data issues that will come as a result of Brexit: Percentage of business that are ready now or will be by 31 October – by sector. In event of a hard Brexit In event of a deal Brexit Construction 41% 38% Tech & Media 40% 40% Health 39% 34% Retail 35% 36% Finance 35% 39% Public Sector 33% 34% Manufacturing 30% 30% Education 29% 35% Professional services 27% 20% Brexit readiness by business size The ThoughtWorks research also found that the size of a business also had a bearing on its perceived readiness for Brexit. Nearly a quarter of small businesses (23%) said they were prepared for the upcoming deadline compared to just (7%) of larger companies[1]. Brexit readiness by city The ThoughtWorks study also explored business sentiment across UK cities. Whilst London is seen to be at the centre of Brexit debate, it was firms in Leeds and Birmingham that were most likely to be fully prepared for the key impacts of Brexit (for both a deal and no deal scenario). In Manchester, business leaders were most likely to say they needed an additional 6-12 months to be ready for the impact of Brexit on their company (39%). Some were calling for even more time – around a quarter of businesses in the Newcastle said they needed until 2021 to be ready (23%) – and some businesses in Liverpool needed five years (13%). Looking at the regional picture, businesses in Scotland and the north were least likely to be prepared for Brexit on 31 October. How long businesses need to adapt to the key regulatory, economic and data issues that will come as a result of Brexit: Percentage of business that are ready now or will be by 31 October – by city. In event of a no deal Brexit In event of a deal Brexit Leeds 57% 46% Birmingham 47% 41% Bristol 40% 29% Cardiff 38% 33% Nottingham 36% 34% London 36% 32% Glasgow 33% 36% Edinburgh 31% 31% Manchester 30% 33% Liverpool 29% 29% Newcastle 28% 22% Kevin Flynn, Director at ThoughtWorks UK commented: “After a period of unprecedented economic and political uncertainty, we asked businesses around the UK how prepared they were for the key regulatory, economic and data issues they believed will result from Brexit. It is a concern that the majority of businesses surveyed say they do not feel they are ready, and this changes little for the deal or no deal Brexit scenarios. “In the weeks ahead, we will look more closely at how businesses plan to adapt to the new post-Brexit era. Supply chain disruption, employment of EU citizens, the falling value of the Pound and transfer of data between the UK and EU are key issues cited today as challenges for businesses. There will no doubt be opportunities from market uncertainty and we expect to see the tech gap widen, as tech-centric agile businesses adapt quickly whilst those whose technology holds them back will likely fall behind or struggle to survive.” Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Advanced Engineering Launches Survey to Gain Industry Views

Advanced Engineering, the UK’s largest annual gathering for engineers, manufacturers and supply chain professionals, has launched its Voice of Industry Survey, which aims to gauge the views of those across the industry. The survey, which questions respondents’ views on topics such as the political climate, the skills gap and the future of the sector, is open for those across the industry to complete ahead of the show on October 30 and 31, 2019. Earlier this year, Advanced Engineering launched its Voice of Industry report, which presented a range of insight from large scale and SME businesses on a variety of industry challenges and topics. Now, the organisers of Advanced Engineering are looking to exhibitors and visitors of the show, as well as those across the wider engineering and manufacturing sector, to provide their views and opinions on the state of the UK industry. “The times we find ourselves in are full of uncertainty, but the UK engineering sector can come out of this era stronger than ever before,” said Jeremy Whittingham, Head of Marketing at Advanced Engineering. “It is our aim to give a voice to the engineering industry to show how resourceful and resilient it can be, regardless of whatever challenges it may face. “By creating a unified perspective from those in the industry, not only will responses help direct us and ensure we are covering topics that are important to our exhibitors and attendees in years to come, it also has the potential to influence industry stakeholders and government directives moving forward. Now, more than ever, those in the industry need to speak up about what kind of support is still needed in order for the UK to prosper.” In addition to its report and survey, the Advanced Engineering show held at the National Exhibition Centre (NEC) in Birmingham, gives exhibitors and attendees the opportunity to network with some 15,000 professionals in multiple fields of engineering and manufacturing. This year Medical Device Engineering will become the sixth show zone, joining zones covering Aerospace, Composites, Automotive, Performance Metals and Connected Manufacturing. To take part in the Voice of Industry Survey, please visit: Voice of Industry Survey. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Cost-Effective 4-Inch POS Printing with Perfect Document Scaling

Cost-Effective 4-Inch POS Printing with Perfect Document Scaling : Say goodbye to inefficient laser printing as global specialist printer manufacturer, Citizen Systems, announces the all-new CT-S4500 POS thermal printer. A new and improved POS printer that’s been designed to serve across multiple applications, with compression driver as standard, the CT-S4500 delivers outstanding economy, printing receipts and labels up to 4-inches wide faster than any other machine in the current POS market. Implementing Citizens rich heritage in printing innovation and manufacturing excellence, the new CT-S4500 brings a new standard to POS printing with its ability to scale down large A4 multi-column documents, for those who need more columns per line, into perfect prints on 4” receipt paper and labels. A feature that’s automatically delivered by the printer’s standard compression driver, this function will deliver convenience and print economy for car rental, betting/gaming, DIY/retail, hospitality and pharmacy businesses. The flat-top, front exit design, a first in Citizen’s 4” POS range, makes the new printer an excellent choice for the hospitality sector as well as making it ideal for integration with kiosks and self-service terminals. Additionally, the CT-S4500’s small footprint and ability to produce quality prints with thicker, luxurious media will appeal to high-end retailers, such as jewellery and designer clothing stores. Furthermore, there will be a label printing version of the CT-S4500 available for ultimate versatility. Available in black or white the CT-S4500 offers ultra-modern aesthetics, making it ideal to fit in with a wide range of working environments. Its supreme performance is designed to withstand daily use, supporting the brand’s reputation of reliability within Citizen’s 4” POS printer range. The printer’s thermal head offers multiples benefits, whilst saving precious time and money without the need to warm up and without the need for toner or ink, (as is typical with laser printers). By printing instantly onto its media, with lower running costs, and delivering 203 dpi prints at market-leading speeds of 200mm/sec, it can replace standard workspace laser printers. Couple these prominent functions with silent, pollution-free operation and a minimal, space-saving footprint, the new CT-S4500 from Citizen is the perfect solution for businesses looking for the ultimate POS printing partner that can do more than just print receipts. Citizen’s newest POS printer comes with full hardware and software connectivity. Standard USB connectivity is supported by an adaptable range of optional interfaces including Wi-Fi, Ethernet, Serial or Bluetooth, making it simple to integrate into existing POS systems. Comprehensive software compatibility includes Windows drivers, Max OS X, Linux CUPS and SDKs for iOS, Android and Windows Mobile as well as industry-standard ESC/POS™® emulation. Using the ESC/POS commands or a Windows driver, the CT-S4500 can print labels without the need for the complexity of traditional label printers. This allows users to adopt systems which may be more familiar to them. The new printer boasts USB charging, meaning it can charge secondary devices such as tablets or scanners and also comes equipped with a full and partial guillotine cutter with a paper saving function for efficient use of media along with label gap and black mark sensors, which are ideal for ticketing and label applications. The new CT-S4500 from Citizen is an ideal POS printing solution for a wide range of commercial environments, producing a variety of printing options with sleek style, practicality and reliability. Jӧrk Schüßler, Marketing Director EMEA at Citizen Systems Europe, said: “Citizen prides itself on its strength in the POS printer industry and the CT-S4500 reinforces this point without question. Thanks to its compression driver, the new printer’s versatility pushes it further ahead of anything else in the current market. We are confident that we have managed to improve upon the hugely successful and trusted CT-S4000. We strive for innovation every day and this new printer stands as a significant development for Citizen, our valued customers and for the market as a whole.” Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Qashqai Production in Sunderland Remains Unchanged

Qashqai Production in Sunderland Remains Unchanged : The plans for Qashqai production in Sunderland have not changed, according to Nissan, although reports stated that the company would review its decision to build the vehicle at the location. But the vehicle maker urged the UK and EU to work together to ensure that an orderly Brexit is achieved. The UK has been a production base for Nissan since 1986, with the Sunderland plant exporting more than half of its production to the EU. The first Qashqai was produced at the plant in 2006 and helped the base build its ten millionth vehicle earlier this year. A statement released by the company said: “Today we are among those companies with major investments in the UK who are still waiting for clarity on what the future trading relationship between the UK and the EU will look like. “As a sudden change from those rules to the rules of the WTO will have serious implications for British industry, we urge UK and EU negotiators to work collaboratively towards an orderly balanced Brexit that will continue to encourage mutually beneficial trade. “While we don’t comment on speculative scenarios, our plans for Qashqai production in Sunderland have not changed.” The SUV accounts for more than two-thirds of the vehicles built at the plant, which employs 7,000 people. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Homeware Manufacturer Registers Turnover Boost

Homeware Manufacturer Registers Turnover Boost : A homeware manufacturer has taken its sales to new heights, while its profits also rose. In the year to 31 December 2019, sales rose to £27.2 million up from £23.6 million in the year prior. Meanwhile, its pre-tax profits rose to £760,000 from £145,000 in 2018. With a history tracing back to 1780, Addis Group manufactures kitchen, garden and bathroom utensils among other products for use in the home. The company was previously located at Upper Bank Works on the outskirts of Swansea, with Addis Housewares now located at the Waterton Industrial Estate in Bridgend. The homeware company drew attention to its newest category, bathroom, as a well-performing part of the business. A statement read: “We are pleased to report that 2018 was another year of progress for the Addis business. “Once again, we saw an improvement in our sales and profit. Our service levels remained at 99 per cent and a quality failure rate that almost, did not register. “All product categories in the business grew strongly. It was particularly pleasing to see our latest category, bathroom, show such strong growth. “Within the sales sectors, particular growth was seen in the grocery, general merchants, hardware, garden centres and department stores.” Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

East Yorkshire Rail Facility Makes Major Appointment

The project team behind the ongoing £200 million rail manufacturing facility in East Yorkshire has been strengthened with a new appointment. Siemens Mobility Limited appointed Mace to support the project, providing a range of services including project and cost management, health and safety work, and environmental expertise. “We are delighted to play a significant role in this innovative project led by Siemens Mobility, which brings together some of the key sectors that are driving the Northern Powerhouse, including manufacturing, industrial development and rail. Our appointment to deliver this important northern asset demonstrates our continued growth east of the Pennines and is a testament to the success of previous projects we have undertaken with Siemens, including Green Port Hull,” said Colin Harvey, Director for the North at the East Yorkshire company Mace. Located on a 104-acre site close to junction 36 of the M62 motorway, the Goole development will include approximately 860,000 sq ft of manufacturing, commissioning, warehouse buildings and stabling sidings, as well as a four-storey, 54,000 sq ft office building. It will create up to 700 jobs with a further 250 during the construction period and an additional 1,700 potential UK supply chain roles. “We’re pleased to be working closely with the Mace team as we drive forward our plans to develop an industry-leading rail factory and related facilities in Goole. Mace’s experience and capability will complement our in-house expertise in the successful delivery of major projects,” added William Wilson, CEO for Siemens Mobility Limited. Construction of the Goole rail manufacturing facility is expected to begin in spring next year and will be delivered in phases. The first phase of the manufacturing facilities is expected to open in 2023 and it is anticipated the development will be fully operational in 2025. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News