A Resicoat powder coating from AkzoNobel has become one of the first products of its kind to complete a 25-year real-world study to prove its ability to protect valves and fittings as the infrastructure of potable water from the damaging effects of corrosion.

The study, conducted in Bad Bentheim, Germany, by an industry association and a water board and verified by the MPA Hannover testing institute, has independently confirmed that Resicoat epoxy powder coating provide durable, long-term anti-corrosion protection for drinking water supply systems.

The results, published this month, demonstrate a new standard in protecting potable water networks and give water infrastructure companies and their customers even greater confidence in the efficacy of their supply infrastructure.

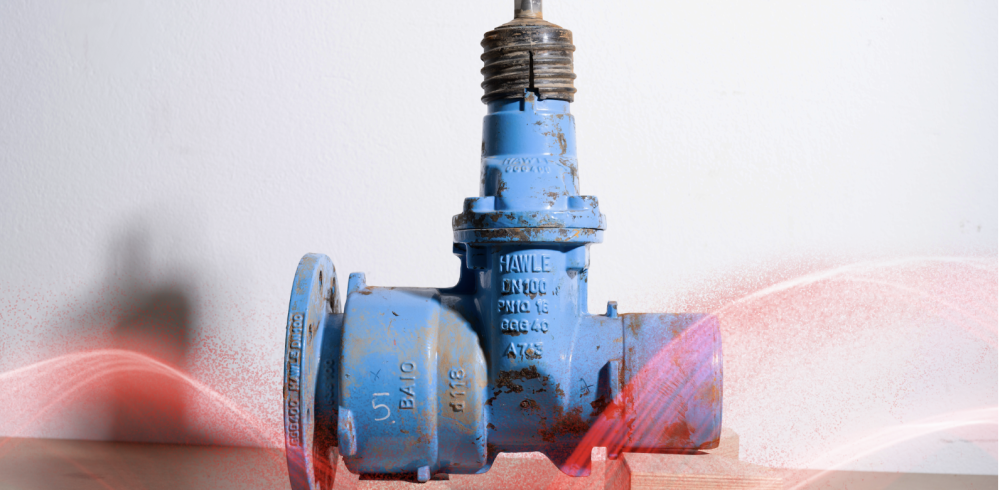

Water systems often fail due to corrosion of pipes and other metal components, such as valves and fittings. Anti corrosion protection is essential to prevent physical failures that can lead to leaking, burst pipes, flooding and unsafe water supplies.

A fully operational test valves and fittings installed in a drinking water pipe had epoxy powder coatings applied before being buried two meters underground, the standard depth for water pipes worldwide.

When the pipeline was unearthed, it showed no leaks and water flowed freely and Resicoat’s epoxy coatings displayed no delamination or cracking. With no impacting signs of corrosion, the results showed the integrity of the pipeline had been preserved.

Yidong Meng, Global Functional Segment Manager at AkzoNobel Powder Coatings, says the tests prove how epoxy powder coatings can deliver the long-term corrosion protection needed to extend the service life of water systems: “In doing so, these solutions make water supply systems more reliable, and help reduce maintenance costs,” he says.

“Epoxy powder coatings are more dependable than ‘traditional’ paint or enamel coatings and consequently help minimize water wastage due to leaks and floods. Ultimately, this ensures a reliable, sustainable source of clean drinking water for millions of people around the world.”

Resicoat R series is high quality thermosetting epoxy powder coating specifically designed for the coating protection of cast iron or steel valves and fittings used in water and gas distribution networks. The powder coating is applied in one layer on a preheated surface by fluidized bed or electrostatic spray application.

Lars Walther, General Manager of GSK, says that the results prove epoxy powder coatings are the best answer to tackling corrosion: “This comprehensive study provides the market with important, independent, and irrefutable proof of the value of epoxy powder coatings in safeguarding the integrity of potable water supplies. It will give even greater confidence to water suppliers that one of the most challenging of all challenging issues to their pipes and associated infrastructure has a credible, long-term solution.”

The Bad Bentheim long-term test involved more than 10 companies and was jointly run by the GSK (Quality Association Heavy-Duty Corrosion Protection of Valves and Fittings with Powder Coating e.V.) and the Wasserbeschaffungsverband Obergrafschaft Bad Bentheim (Water Supply Association of Upper County Bad Bentheim and Surrounding Areas).

You can find more information about Resicoat solutions for valves and fittings on our website:

https://www.interpon.com/products/functional/resicoat-r

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News