Rolls-Royce, through its Power Systems division, and CATL, a global leader of new energy innovative technology, have signed a strategic co-operation agreement to launch CATL’s new TENER product line in the European Union (EU) and UK. The partnership will strengthen the ability of both companies to realise large and complex grid-scale battery energy storage system (BESS) projects. The two companies have already successfully delivered several projects in the EU using CATL’s EnerOne product line, with several others already under contract.

Rolls-Royce’s Power Systems division, which has decades of experience in power generation and the energy industry, has already started to offer TENER products, characterised by their increased safety, long service life and heightened efficiency, as part of its mtu EnergyPack QG solution for large-scale energy storage, primarily for grid operators. The new strategic partnership includes the potential development of further innovative smart products, based on Rolls-Royce’s intelligent automation solution, mtu EnergetIQ, and its digital platform, mtu Go!, as well as CATL’s intelligent diagnostic platform and battery management system.

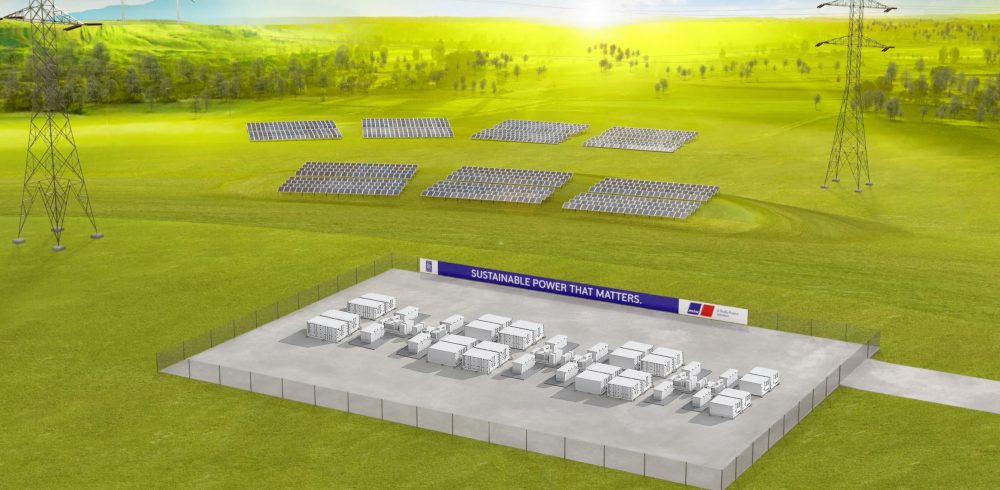

Large, or grid-scale, energy storage systems enable the integration of renewable energy sources, which may have intermittent or variable output depending on weather conditions, into an energy grid while increasing stability and reliability. This fully integrated solution enables customers to utilise the latest grid and trading services, while supporting the energy transition by creating a more sustainable energy infrastructure. Battery storage systems are a strategic focus and area of growth for Power Systems, as highlighted at Rolls-Royce’s Capital Markets Day last November.

Last year, Rolls-Royce and CATL signed a long-term supply agreement to collaborate on more than 10 Gigawatt hours (GWh) of storage capacity. Together, the two companies have built a close working relationship on the integration of TENER products into fully fledged EPC-turnkey projects with an all-inclusive service offering. Depending on the specifications and exact usage, the new TENER product can achieve zero degradation in the first five years of use.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News