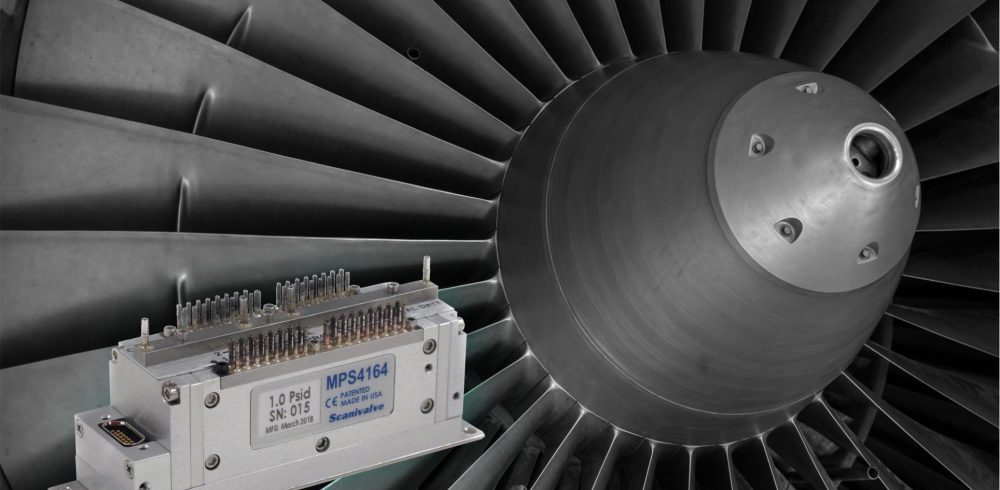

Scanivalve has developed the MPS4264 Miniature Pressure Scanner, a compact, intelligent pressure measurement system engineered to deliver high-accuracy data in real time. Designed for use in demanding environments such as aerospace testing, automotive development, HVAC systems, and industrial R&D, the MPS4264 integrates advanced signal processing capabilities directly within the unit.

Unlike conventional pressure scanning systems that require external signal conditioning or post-processing, the MPS4264 performs onboard conversion of raw sensor data into calibrated engineering units—including pressure (Pa, psi, bar) and temperature-compensated outputs—enabling direct integration with DAQ systems or control units without intermediate data handling.

The pressure scanner incorporates internal calibration and thermal compensation algorithms, contributing to improved measurement accuracy and repeatability across varying operating conditions. Communication is supported through multiple interface options, including analogue voltage output, CANbus, and Ethernet, allowing seamless compatibility with diverse test architectures.

By removing reliance on external processing hardware, the MPS4264 reduces system complexity and accelerates data availability, supporting faster decision-making during testing scenarios. Its autonomous operation makes it suitable for applications ranging from wind tunnel testing and engine development to environmental monitoring and complex system diagnostics.

Paul Crowhurst, Managing Director at Evolution Measurement, Scanivalve’s UK sales partner, commented:

“The MPS4264 represents a shift toward smarter, more responsive pressure measurement technology, providing meaningful insight exactly when it’s needed.”

For further information on how the MPS4264 can enhance your pressure measurement workflows, visit EvolutionMeasurement.com or contact +44 (0)1264 316470.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News