The UK Government has awarded funding to a consortium led by Morek Engineering to design a new class of low-carbon installation vessel for the floating offshore wind market.

The consortium has won the funding through the UK Government’s Clean Maritime Demonstration Competition based on their proven track record in innovative vessel design and delivery of complex offshore operations. The consortium includes Morek Engineering, Solis Marine Engineering, Tope Ocean, First Marine Solutions and Celtic Sea Power.

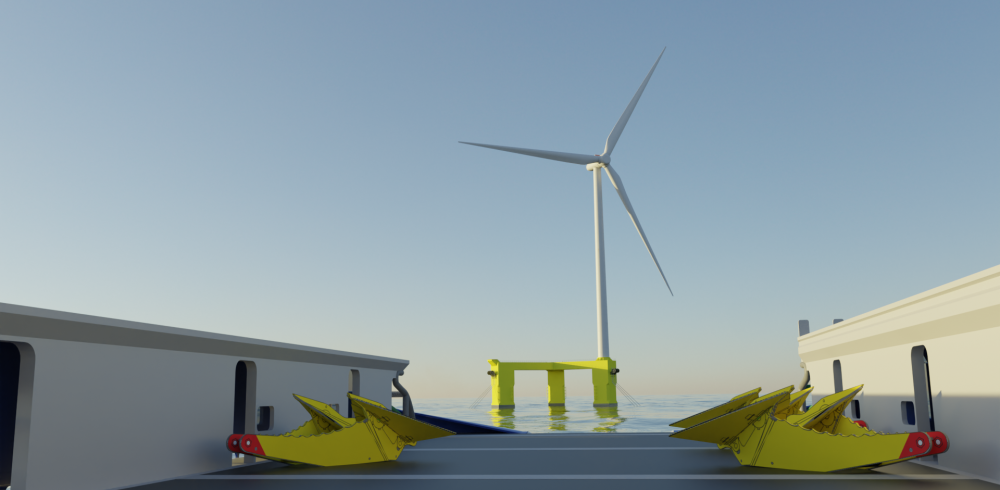

Bob Colclough, MD of Morek Engineering, says: “This will be a first-in-class low-carbon vessel designed specifically to meet the complex installation requirements of floating offshore wind farm moorings and foundations. The project aims to align the detailed requirements of the emerging Floating Wind sector with the objectives of the UK maritime decarbonisation agenda.

“As the next era of offshore wind development moves towards using floating foundations, unlocking deeper sites and accessing stronger winds further from shore, this will involve mooring floating foundations to support the world’s largest offshore wind turbines, some the size of the Eiffel Tower.

“The current offshore service fleet has limited capability and capacity. To reach the ambitious Net Zero targets set out by the UK government and other governments around the world, the offshore construction market will need to reach a serial production level which is unprecedented in offshore industries. Floating offshore wind needs a cost-effective solution to deliver serialised installation of huge moorings and floating foundation systems, whilst minimising carbon emissions during the construction and maintenance of the next generation wind farms. We are going to develop the next generation of offshore wind construction vessels, meeting the challenge head on.”

This project is part of the Clean Maritime Demonstration Competition Round 4 (CMDC4), funded by the UK Department for Transport (DfT) and delivered by Innovate UK. CMDC4 is part of the Department’s UK Shipping Office for Reducing Emissions (UK SHORE) programme, a £206m initiative focused on developing the technology necessary to decarbonise the UK domestic maritime sector.

Ian Godfrey, MD of Tope Ocean, explains: “To indicate the scale of the decarbonisation challenge, greenhouse gas emissions from offshore wind farm operation and maintenance vessels constituted more than 3% of domestic shipping emissions in the UK in 2022. With ambitious targets to develop the UK’s offshore wind capacity from 14 GW in 2023 to 50 GW by 2050, this percentage share is likely to rise to well over 10% as this pipeline is realised through a ‘business-as-usual’, fossil fuel vessel scenario. So it is vital to pioneer a new approach to offshore service vessels, to embrace Clean Maritime and Net Zero objectives.

“We will undertake a highly detailed feasibility study into the requirements of the emerging global floating offshore wind sector for a new class of low-carbon installation vessel. The new vessel will be designed to carry out complex, high-energy construction tasks within the duty cycle constraints of future low and zero-carbon fuel systems. It will set a new standard for environmental performance associated with the construction and maintenance of floating offshore wind and the wider marine transportation sector.”

Bob Colclough comments: “An extremely wide range of mooring and foundation technologies are expected in future floating offshore wind projects around the world. So, we are undertaking a detailed stakeholder and end-user engagement process so that the design of our new vessel takes account of this and is future-proof.”

The outline vessel design will be ready for engagement with classification societies to achieve approval in principle by early 2025.

Bob Colclough adds: “We are aiming to be included in the national shipbuilding strategy, cementing the UK position to deliver Net Zero 2050. Our next generation vessel will help accelerate the growth of the floating offshore wind market around the world, providing low-carbon installation and maintenance.”

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News