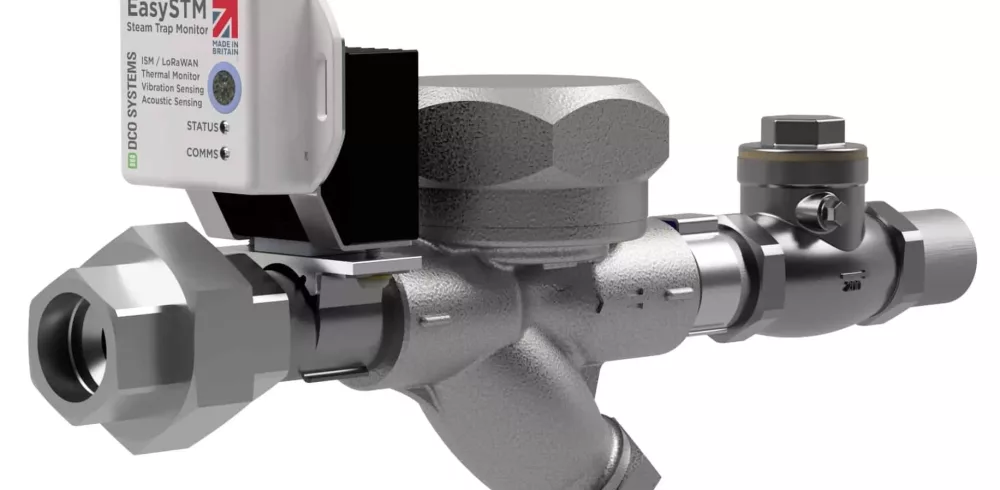

Large scale production of DCO Systems’ new steam trap monitor- the Easy STM is scheduled to begin next month. Design and development were led by DCO’s founder, Andrew Doherty.

Andrew states, ‘Our experience with trap monitoring found there often isn’t much room to install steam trap monitoring equipment. Our new monitor is significantly smaller and needs only 25mm (1”) of exposed pipework, and can be more easily fitted near flanges, unions, and insulation jackets.’

The new model is designed for mass installation on drip and line traps and provides thermal, movement and environmental monitoring. Two immediate benefits include the ability to significantly simplify installation and reduce costs on lower value traps. Compared to DCO’s older model, the ‘Base STM’, further improvements to functionality include:

- Each packaged version supports at least two different pipe sizes, simplifying installation and reducing need to determine all pipework sizes at time of order.

- Only one leaded sensor needs to be fitted opposite the main installation location. With a stainless-steel armoured lead, the sensor is now tougher and more compact than previous versions.

- Direct mounting of the unit to pipework adjacent traps improves the effectiveness of integrated movement and vibration detection for pipework and traps.

The Easy STM is also battery-free and self-powering. Key features include an optional upgrade for acoustic environmental sensing, ‘out of the box’ support for DCO’s DiscoverRA cloud platform or integration with in-house platforms, flexible mounting sizes, predictive maintenance, and smart reporting intervals and up to 20 updates per hour.

‘The functionality of the DiscoverRA dashboard for the Easy STM has also been redeveloped. Now, you can add extensive asset and operational data for each trap and including GPS location, internal distances and datums. Furthermore, there are tabs for equipment type, images, charts and graphs and real-time alerts. The focus has always been what is most useful for engineers, and we believe we have achieved that’, adds Andrew.

DCO Systems also offer Flex STM and Ultra STM steam trap monitoring models. The Flex STM is a larger IP66 model that provides a monitoring platform that offers sensor flexibility to meet requirements. And the Ultra STM model provides thermal and ultrasound monitoring for higher-throughput traps in process applications. Furthermore, clients can benefit from a complete monitoring solution that includes both the Gateway and Dashboard analytics.

Since 2016, DCO Systems have been at the forefront of steam trap monitoring solutions, bringing simplified and effective tools to manufacturers in the UK, Europe, Africa and North America.

To learn more and register your interest, contact us or email info@dcosystems.co.uk.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News