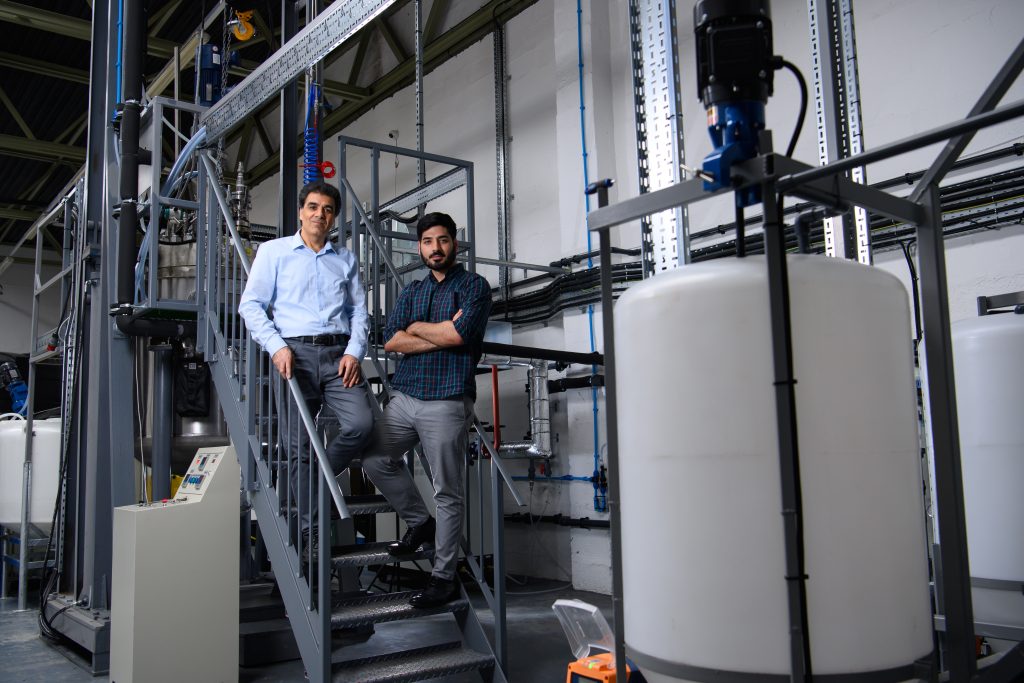

Integrals Power Pioneers Pilot Line

Integrals Power, a pioneering producer of next-generation battery materials, is continuing its strategic growth by opening up its state-of-the-art UK pilot plant to third-parties. Offering a pilot line as a service is unique. By making its R&D and manufacturing capabilities available to other companies, Integrals Power will help to accelerate innovation in the battery sector by enabling them to progress from materials production at lab-scales of a few grammes up to multi-tonne levels. This latest milestone is part of Integrals Power’s continuing expansion as it seeks to scale-up production of its own proprietary LFP and LMFP cathode active materials into the hundreds of tonnes and commercialise the technology, spearheading the creation of a world-class domestic supply chain for batteries. Already verified through independent testing by experts at the Graphene Engineering Innovation Centre, Cranfield University and QinetiQ, samples are currently being assessed by several customers in Europe and the US, including global vehicle OEMs. Integrals Power Founder and CEO, Behnam Hormozi, said: “Our company was founded on innovation and advanced research in battery materials, so pioneering the concept of the pilot line as a service is in our DNA. As we progress to the next stage in our strategic growth, we’re proud to offer both our manufacturing and R&D capabilities to other stakeholders in the sector because collaboration has a fundamental role to play in accelerating more sustainable e-mobility and energy storage technologies.” Integrals Power has already used the pilot line to develop a breakthrough LMFP chemistry featuring 80 per cent manganese, enabling an increase in energy density that could increase electric vehicle range by up to 20%, while delivering high performance without compromising durability – and at less cost that Nickel Manganese Cobalt (NMC) chemistries. Opening up the facility to third-parties will enable them to progress their own development programmes and help to meet rising demand for more efficient, more sustainable, and more transparent energy storage solutions. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

NORD ECO Service Uncovers Savings Potential at Airports

To support airports in designing energy-efficient baggage handling systems, NORD DRIVESYSTEMS offers the NORD ECO service. The North German company thus makes a significant contribution to achieving the climate targets in this sector. NORD is a system supplier of innovative drive solutions for more than 100 industries. With the NORD ECO service, the drive specialist has already helped many companies to improve their system’s performance and energy efficiency through modernisation and to reduce the variants of the components used. Energy-efficient systems at airports“Baggage handling systems often offer potential for savings, especially when considering the drive technology”, reports Jörg Niermann, Head of Marketing at NORD DRIVESYSTEMS. “We offer our NORD ECO service to optimise existing installations and to find the best drive solution.” The NORD ECO box conducts comprehensive measurements over a period of at least two weeks. Based on permanent loads, load peaks or irregular conditions, it becomes clear whether a system’s dimensions match the requirements of the respective application. “We often encounter drive systems that are clearly overdimensioned for the corresponding application, and so we develop a new solution”, Niermann adds. The installation of an alternative system is followed by a comparative measurement with a final analysis. “In conclusion, the NORD ECO process achieves lower energy consumption and costs as well as reduced CO2 emissions.” This allowed NORD to reveal significant savings potential for the drive systems in baggage handling systems of different airports and to implement alternative solutions. Savings potential in numbersAt an airport that was already using an energy-efficient drive concept with IE3 motor, the measurement with the NORD ECO service concluded that almost 20 % of energy could be saved by using a DuoDrive solution with IE5+ motor and a decentralised NORDAC LINK frequency inverter. After a comparative measurement of both systems over a period of a little more than a year, it was possible to finally determine a savings potential of 590 kWh and 396 kg CO2. Airports that used a DuoDrive solution with a NORD IE5+ motor in their baggage handling systems instead of drive systems with an IE1 motor were able to achieve a savings potential of up to 48 %, reducing the application’s annual CO2 emissions by up to 144 kg in calculation. The DuoDrive’s low operating temperatures and the option for variant reduction also proved to be beneficial. The additional costs for more efficient drive systems are quickly amortised thanks to government funding. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Back British Metals: New Campaign

A powerful new campaign, Back British Metals, has launched with a direct call to Government: ensure metals are recognised as strategically essential in the forthcoming UK Industrial Strategy and Critical Minerals Strategy. Building on the recent Government intervention to safeguard British steelmaking, the campaign welcomes this support as a first step, but warns that a broader, more inclusive metals strategy is now urgently needed. The Back British Metals coalition is asking Government to show the same bold ambition across the entire UK metals sector, including aluminium, copper, cobalt, lithium, steel, and the platinum group metals (PGMs). At the heart of the campaign is a Parliamentary Pledge Event, planned at 10am – 12noon on Tuesday 20th May, where MPs and Ministers will be invited to sign a formal commitment to Back British Metals and show their support for the sector. The Mission Back British Metals is a national call to recognise and strengthen the UK’s capability to produce, process, and recycle essential metals. From strategic energy pricing to smarter procurement, the campaign is focused on building a more resilient and competitive domestic metals sector – one that enables decarbonisation, supports economic security, and underpins the UK’s long-term industrial growth. At its core, the campaign seeks to align UK policy with industrial capability, so that foundational metals are not only protected, but championed as part of a joined-up industrial vision. Why Now? Metals are the foundation of Britain’s industrial strength. From aluminium and copper to steel and the platinum group metals, they are critical to the UK’s clean energy transition, defence resilience, infrastructure, and advanced manufacturing sectors. Despite this, too many strategic metals supply chains remain undervalued or at risk. Rising industrial energy prices are damaging UK competitiveness. Strategic-grade scrap is being exported instead of reused domestically. And current policy frameworks often overlook foundational metals in both industrial and critical materials planning. Without a coordinated, cross-cutting strategy, the UK risks weakening its own industrial capabilities at a time when resilience, energy transition and international competitiveness are more important than ever. Metals must be understood not as commodities, but as core enablers of the UK’s future economy. A Cross-Sector Call to Action The Back British Metals campaign urges the UK Government to adopt a joined-up, whole value-chain approach to industrial strategy, underpinned by tangible policy measures. Specifically, we are calling on Government to: 1. Include metals and foundation industries as core enablers of all eight growth sectors in the UK Industrial Strategy. 2. Adopt a full value chain approach across both Industrial and Critical Minerals strategies, encompassing mining, processing, fabrication, manufacturing and recycling. 3. Ensure the Critical Minerals Strategy is inclusive, explicitly recognising aluminium, steel, copper, platinum group metals and other strategic materials beyond rare earths. Get Involved This is a call to action for the entire UK metals sector. Back British Metals will be hosting a Parliamentary Pledge Event on Tuesday 20th May, inviting MPs, Ministers, and industry leaders to demonstrate their support by signing the pledge and backing a truly strategic approach to UK metals. We urge stakeholders across all metals sectors to get involved, show support, and help deliver a unified message to Government. Let’s make this a turning point. Let’s Back British Metals. Visit www.alfed.org.uk – The Voice of the UK Aluminium Industry Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Fersa Brings Fuel-Saving Technology to Automec 2025

Fersa, the global leader in high-performance bearing and powertrain solutions, will showcase its cutting-edge Fuel Efficient Wheel Hub Assembly technology at Automec 2025, a leading auto parts trade show in Latin America, taking place April 22–26 at São Paulo Expo, Brazil. With fuel costs and emissions pressures mounting across Latin America for commercial vehicle fleet operators, Fersa’s advanced Fuel Efficient Wheel Hub solution delivers independently validated fuel savings of at least 3% for a truck and trailer combination, translating to real-world savings of up to R$ 11.466 per application annually. Developed through a rigorous one-million-kilometer global validation program, the Fersa commercial vehicle technology optimizes friction and durability for demanding, high-mileage conditions common across the region. Fersa’s Fuel Efficient Wheel Hub Assembly is the culmination of years of applied engineering, developed to maximize performance through micro geometric precision, high-spec materials and a fine-tuned lubrication architecture that cuts rolling resistance and enhances mechanical efficiency. By optimizing contact surfaces, reducing internal friction, and incorporating robust sealing technology, the system delivers tangible fuel savings without sacrificing durability. Engineered for high-load environments, it stands up to the intense demands of industrial and commercial transport – delivering reliable, long-life performance even under the toughest operating conditions. Fersa’s presence at Automec marks a key moment in its Latin American growth strategy, as the company looks to deepen relationships with regional fleet operators, distributors and industry leaders. Alongside the Fuel Efficient Wheel Hub innovation, visitors to the stand will discover the latest in light commercial vehicle differential repair kits, also optimized for emerging markets. The F-Box Differential Repair Kit combines OEM-grade bearings and a tapered roller tech within a simplified all-in-one package that is easy to install, reduces wear and boosts lifespan – making the solution an ideal fit for Latin America’s growing independent repair market. “Automec is a crucial meeting point for Latin America’s transport ecosystem – and we’re proud to showcase technologies that deliver proven efficiency and lasting value,” said Rafael Paniagua, CEO of Fersa. “Our Fuel Efficient Wheel Hub solution is engineered with real-world durability in mind, offering fleet operators and repair professionals a smarter path to performance, savings and sustainability.” Fersa’s team will be on-site throughout Automec to share insights into the engineering behind its tech solutions and connect with operators, distributors and workshop professionals from across the continent. Journalists attending Automec 2025 – or following Fersa developments remotely – can arrange one-to-one interviews with Fersa executives or engineers. To book a session, email: press@fersa.com. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Resistors Help to Get the Most Out of Wind Power

In January 2025, the UK government announced new measures to unlock up to thirteen major wind projects as part of its Plan for Change. But with wind curtailment — the switching off of wind turbines — reaching record levels in 2024, how can we make the most of the energy generated? Here, Mike Torbitt, managing director of resistor manufacturer Cressall, explores the role that resistors can play in preventing the wastage of wind power. The government’s Plan for Change aims to modernise the ‘outdated and archaic’ infrastructure regulations to increase the pace at which offshore wind projects are constructed. In total, the measures could generate up to 16 Gigawatts (GW) of electricity and around £20-30 billion of clean energy investment. The announcement is promising, but much of the newly harnessed wind power could be wasted. Turbines are frequently turned off in periods of high wind, to protect the grid system from being overwhelmed by the power generated. According to a report from electricity supplier Octopus, enough energy was wasted in the first nine months of 2024 to power two million UK homes for a year. Not only does wind curtailment limit the UK’s ability to fully transition to clean energy, but it also results in higher bills for consumers. And the problem is growing — the costs of wind curtailment will reach £3.7 billion by 2030. As the UK continues to invest in wind power, it’s important that additional energy generated is put to good use. So, why is energy being wasted and how can this be prevented? Distance issues The key reason for switching off wind turbines is distance — both from the grid and from demand. Offshore farms are much further from the grid than their onshore counterparts, meaning there are less readily available connection points to distribute power to the transmission network. Consequently, in the case of strong winds, there are fewer options available to distribute the energy elsewhere. The remote location of offshore windfarms also means they are located far from high-demand areas. For example, Scotland currently has seven operational offshore windfarms, many of which are located near the north of the country where population density is low. Demand for energy is greater elsewhere, but inefficient cable networks mean that a lot of power is lost during transmission. Handling the excess Energy experts have several suggestions on how to tackle wind curtailment. For instance, the Octopus report recommends zonal pricing, which means that people living near turbines can benefit from cheaper energy rather than it going to waste. The research suggests that businesses could save in the region of 65 to 99 per cent on energy costs by moving to Scotland and benefitting from zonal pricing. While the prospect of lower bills would hopefully encourage people to welcome the development of renewable energy projects within their communities, moving to energy-abundant areas isn’t feasible for all businesses. Another way to minimise wastage is by improving the infrastructure that transmits energy from offshore sites to high-demand areas. In March 2025, construction will begin on the Eastern Green Link 1 (EGL1), which will enable the transmission of energy from Torness in Scotland to Hawthorn Pit in the North East of England. Once complete, the high-voltage direct current (HVDC) project will deliver enough electricity for two million homes. HVDC enables efficient power transmission over long distances between offshore wind farms and the grid, thanks to its consistent current density. Resistor technology is essential in HVDC systems, safeguarding against grid failures by absorbing excess wind energy until the transfer is safely halted. Additionally, DC neutral earthing resistors provide further protection to the system, both onshore and offshore, within HVDC converter transformers. Cressall has extensive experience in supplying resistors for renewable projects, including a GE Vernova partnership covering five HVDC projects in the North Sea. The government’s aim to amend inflexible planning restrictions and boost wind power generation projects through its Plan for Change initiative is a welcome development. However, to create real change, the rollout of energy transmission projects must keep pace with offshore wind developments. HVDC systems supported with reliable resistor technology will enable the UK to reduce wind curtailment and make the most of the renewable resources available. Contact a member of the Cressall team for advice on selecting the right resistors for your renewable project. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Oman Oil and TFG Marine Establish Bunker Fuel Joint Venture

Oman Oil Marketing Company (OOMCO) and TFG Marine, the leading international marine fuel joint venture founded by Trafigura, Frontline and Golden Ocean, have established a bunker fuel joint venture to supply vessels visiting Oman’s ports of Duqm, Muscat and Sohar. TFG-OOMCO LLC, incorporated in Oman, will combine the local knowledge of OOMCO with the international footprint, sourcing of all grades of marine fuels, infrastructure and logistics capability of TFG Marine, to offer customers a reliable and transparent bunkering provider in the Arabian Gulf. As stated by Mr. Tarik Al Junaidi, the CEO OF Oman Oil Marketing Company: “This partnership aligns with Oman Oil Marketing Company’s efforts to develop the maritime transport and shipping infrastructure in Oman, which is in alignment with the objectives Oman Vision 2040. It underscores our commitment to meeting the increasing demand of compliant, high-quality marine grades of fuel while adhering to the highest international health, safety, and environmental standards. Through our partnership with TFG Marine, the adoption of cutting-edge technologies and the implementation of global best practices in fuel bunkering, we strive to lead towards excellence and sustainability in the bunker fuel business in the Sultanate’s ports.” Mr. Mark Russell, Chief Commercial Officer, TFG Marine added: “This is TFG Marine’s first venture in the Middle East and we look forward to serving our customers in this region. Oman has a rich history as a maritime nation and is well located close to the main shipping routes connecting the Arabian Gulf and the Indian subcontinent with the rest of the world.” Today’s announcement follows the signing of an MOU agreement between SOHAR Port and Freezone and TFG Marine, to establish an international bunker fuel supply operation. TFG Marine’s has already deployed bunker vessel the Margherita Cosulich to the region to supply vessels at SOHAR’s deep-sea port. The vessel is fitted with a Mass Flow Meter (MFM), calibrated to the ISO 22192 international standard as required by SOHAR Port. TFG Marine has long been an advocate of the global adoption of calibrated MFMs to bring much-needed transparency to bunkering and encouraging digitalisation in the long-term interests of the bunker industry and helping to further the decarbonisation goals of the shipping industry. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

SLS Earns 5 Lab Awards Nominations

Scientific Laboratory Supplies (SLS), the UK and Ireland’s leading independent laboratory equipment distributor, has earned five nominations at the Lab Awards 2024, held at the Lab Innovations exhibition at the NEC, Birmingham, on October 30. As well as four product ‘Innovation’ nominations, the laboratory supplier hopes to win the ‘Supplier Excellence’ award in recognition of its newly opened National Distribution Centre (NDC). SLS is also proudly sponsoring the ‘Lab Technician of the Year’. SLS’s full list of award nominations at the upcoming Lab Awards 2024 includes ‘Best Sustainable Innovation’, ‘Best Consumables Innovation’, ‘Best Technology Innovation’, ‘Best Automation and Data Innovation’ and ‘Supplier Excellence’. The laboratory equipment distributor, exhibiting from stand K80, has the most nominations of any participant at this year’s awards and seeks to improve on its two awards won at Lab Innovations 2023. “The five nominations at this year’s Lab Awards continue a tremendous year for SLS,” said Ian Roulstone, managing director at SLS. “As Lab Awards sponsors, we know the importance of recognising excellence in the scientific community.” Amongst the technology on display on stand K80, SLS will exhibit the four award-nominated products at this year’s Lab Innovations that it has played a key role in distributing and promoting across the UK and Ireland. They include Eppendorf BioBased epT.I.P.S pipette tips, which use a second-generation bio-based polymer made from at least 90 per cent renewable resources. These renewables include waste and residues from vegetable oil refining or waste cooking oil. The product is nominated in the ‘Best Sustainable Innovation’ category. SLS will also exhibit the Merck Stericup E, nominated for ‘Best Consumables Innovation’. The product uses a funnel-less design in sterile vacuum filtration to reduce the plastic and packaging involved. It will appear alongside the Innovaprep Concentrating Pipette Select Automated Bio-Concentrator. Nominated for the ‘Best Technology Innovation’ award, the rapid bio-concentrator delivers rapid filtration and instant recovery of biological samples. This improves sensitivity for pathogen detection by any analysis method. Finally, the FluidX Automated Plate Seal Remover is nominated for ‘Best Automation and Data Innovation’. It automatically removes seals from a wide range of microplate types with one button, eliminating the need for mechanical removal mechanisms. “In addition to the product awards, we’re also pleased to have been nominated in the ‘Supplier Excellence’ category,” added Ian Roulstone. “This recognises SLS’s recent move to its new NDC at Fairham Business Park in Nottingham. The facility has already helped triple our daily number of serviced orders to 2,500 per day, reflecting how SLS prioritises customer needs and service.” Meanwhile, SLS will sponsor the Lab Awards 2024’s ‘Lab Technician of the Year’. Nominees include several technicians that work closely with SLS. They are Robin Parsons of Staffordshire University, Dr Nicky Morgan of the University of Salford, Alex Bird of the UK Biocentre, Lee Hibbett of the University of Nottingham’s School of Pharmacy, Wewerly Fernandes of The Open University, Sophie Galloway of the University of Nottingham and Graham Hickman of Nottingham Trent University. Read more about SLS’s award-nominated laboratory products here and register for Lab Innovations ahead of the Lab Awards 2024 ceremony on October 30. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News