Compact 5-Axis Machining Centre Has Many Options, Including Ultrasonics

Occupying just 3.8 square metres of space on the shop floor, a new, 5-axis machining centre with a working volume of 220 x 370 x 290 mm has been introduced by DMG Mori. The new DMU 20 linear is capable of a wide range of applications, from micro-machining of watch components, through EDM electrode and impeller production, to die and mould making. A rigid, FEM-optimised cast bed and thermo-symmetrical gantry design have been coupled with Magnescale axis position measuring systems to ensure long-term stability and a high level of machining accuracy to within single-figure microns. The A-axis trunnion swivels from +130 to -93 degrees, allowing flexible machining strategies and enhancing the operator’s view of the workpiece. The C-axis table rotates at up to 150 rpm, optionally 1,500 rpm, and it can be positioned to an accuracy of two arcseconds. Zero-point clamping is standard, with the customer able to choose Erowa, Schunk or another make. There is also provision for vacuum clamping of delicate or thin-walled workpieces. The machine is equipped with a powerful Fischer spindle (HSK 32, 42,000 rpm) as standard, although HSK 32 or HSK 40 spindles up to a maximum of 60,000 rpm are available. If elevated levels of precision are required combined with long running times, a shaft-cooled version is available for the HSK 40 variant. The tool magazine offers 26 pockets, or optionally up to 60 tools, suitable for flexible production requirements with frequent tool changes. The DMU 20 linear enables efficient and productive machining through the integration of tool measurement using a Blum laser system in the working area, integrated into the side of the machine table. In preparation for the measuring cycle, the A-axis is swivelled through 90 degrees. Numerous other options allow the DMU 20 linear to be customised. Examples are a treatment package to allow oil to be used as a coolant, oil-resistant hoses and electrostatic extraction of fine particulates. There is an interface for a conventional or a CO2 fire extinguishing system. In addition, a digital camera is available to provide a clear view of the machining process. DMG Mori developed the DMU 20 linear to be easily automated via a plug-and-play interface, for example with the manufacturer’s own PH 10, PH 50 or MATRIS light systems. The intuitive CELOS X user interface on a Siemens SINUMERIK ONE control paves the way for networked production and digitalised processes. Innovative GREENMODE hardware and software reduce energy consumption by over ten percent, enabling more sustainable manufacturing. For machining hard, brittle materials such as glass, Zerodur or technical ceramics, the machine is available as a third-generation ULTRASONIC 20 linear. In this machine, tool rotation is superimposed with an additional ultrasonic oscillation, reducing the force generated by the tool during machining by up to 50 percent. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Additive Manufacturing UK to Represent the UK at Formnext 2026

Formnext, the world’s leading exhibition for additive manufacturing, has named the UK as its partner country for the 2026 exhibition. Taking place from 17–20 November in Germany, Formnext 2026 will once again serve as the global hub for additive manufacturing, industrial 3D printing and the next generation of intelligent manufacturing solutions. Additive Manufacturing UK (AMUK), as the only trade body representing UK companies in this industry, is perfectly positioned as the representative to showcase the UK’s innovation and leadership in this field. AMUK membership consists of UK companies across the entire additive manufacturing value chain, from materials manufacture to post-processing of parts. Formnext is renowned for bringing together more than 800 exhibitors representing every stage of the additive manufacturing process chain, with 61% of participants coming from international companies. Over its four-day duration, the event attracts more than 34,000 visitors from across all key manufacturing sectors, nearly half of whom travel from outside Germany to attend. Each year, the exhibition organisers select a partner country based on a comprehensive assessment of global additive manufacturing activity, considering factors such as the size of the AM industry, user industries and the scale of R&D and innovation. The position is awarded to a nation demonstrating a rapidly expanding AM market supported by a dynamic and well-connected industry community. Joshua Dugdale, Head of AMUK, said: “We’re delighted that the UK has been selected as Formnext’s partner country for the 2026 expo, and AMUK is excited to be representing the UK.” He continued: “Additive manufacturing has enormous potential to transform the way we design and produce parts and products. That’s why we support our members and the wider UK industry across the entire AM value chain, whilst also educating potential users about the opportunities this technology offers. The UK AM industry is set for significant growth, driven by benefits such as reduced waste, greater efficiency and lower production costs for small-batch manufacturing.” The UK share of the global AM market is currently around 4-5.5%, which values it in the range of $0.90 billion (£720 million) to $1.22 billion (£900 million). There is an exciting opportunity for this market share to grow through increased levels of support in the UK. The calculations show that, based on the level of AM R&D being undertaken in the UK, around 7% of the global market could be captured by the UK. This would value the market in excess of $6 billion by 2030. AMUK will lead the UK’s presence at Formnext 2026 through a dedicated national pavilion and coordinated programme of events. This partnership will highlight the UK’s advanced capabilities in additive manufacturing and provide a significant platform for UK businesses to connect with global industry leaders, explore new markets and foster international collaboration across the sector. Joshua Dugdale commented: “I would encourage all AMUK members and companies within the wider AM sector to take up this fantastic opportunity to exhibit at Formnext 2026. Any companies that book well in advance can take advantage of Formnext early-bird discount.” This collaboration is recognition of the UK’s growing influence in the global additive manufacturing landscape and reflects the sector’s strategic importance to the country’s advanced manufacturing ambitions. AMUK aims to strengthen the international reputation of the UK’s innovation, research excellence and industrial capability, positioning the UK as a leading contributor to the future of intelligent manufacturing worldwide. For more information about Formnext 2026, please visit: https://formnext.mesago.com/frankfurt/en.html and AMUK: https://additivemanufacturinguk.org.uk/ Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

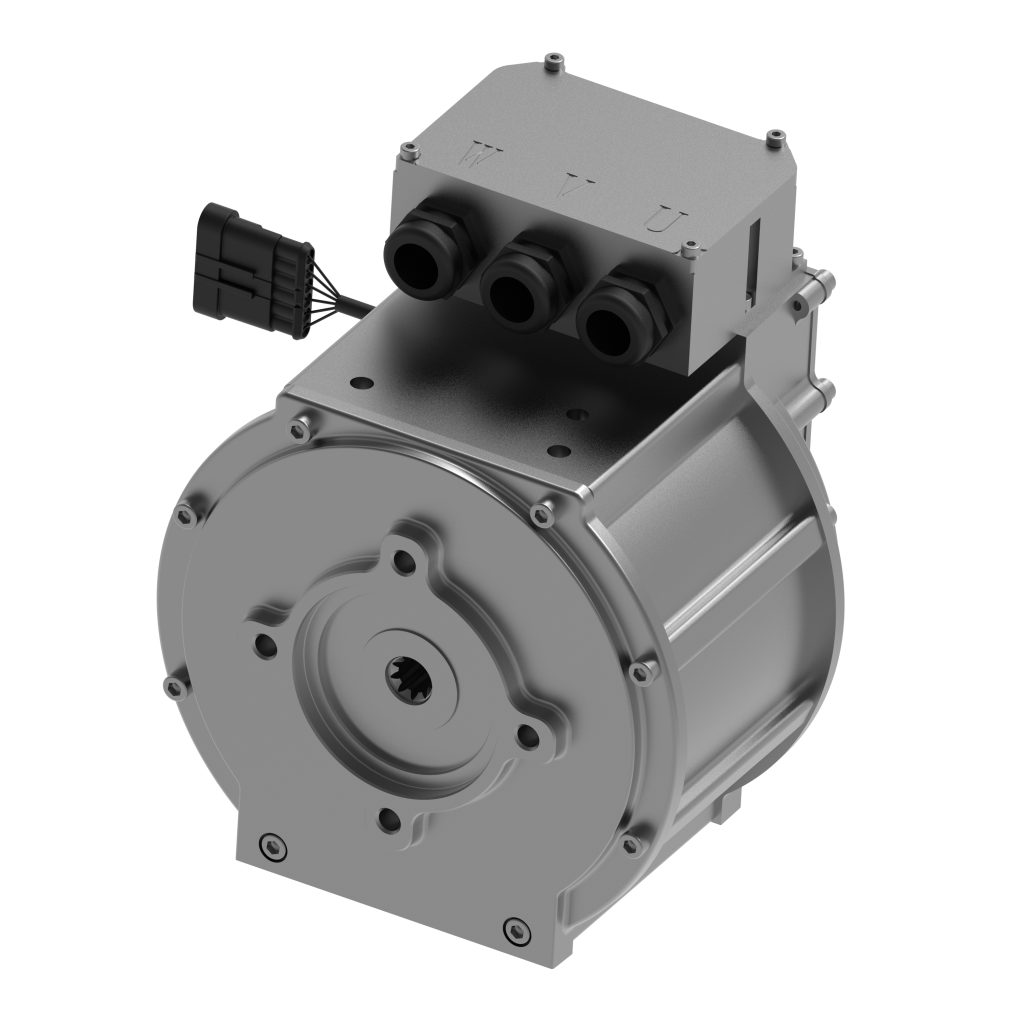

New Danfoss Editron EM-PMI180

Danfoss Power Solutions has announced the launch of its Editron EM-PMI180 low-voltage electric motor. The 48-volt synchronous reluctance assisted permanent magnet (SRPM) motor is designed to drive a hydraulic gear pump in compact electric machinery, powering the machine’s work functions. The PMI180 motor features a compact, robust design delivering high power density and efficiency. Ideal applications include boom lifts, scissor lifts, and compact loaders and excavators. Most manufacturers of mobile elevating work platforms (MEWPs) utilize AC induction motor (ACIM) systems to drive the hydraulic pump powering the machine’s lift function. These motors are bulky and inefficient, and today many MEWP manufacturers are switching to newer SRPM technology. Compared to ACIM, SRPM technology offers higher torque, higher power, and a more compact design. The Editron PMI180 motor exemplifies this difference, delivering greater efficiency and torque in a smaller envelope than typical AC induction motors. The PMI180 features hairpin windings, which further increase motor power density and efficiency compared to conventional round wires. The PMI180 motor features a 15% smaller envelope than AC induction motors with the same torque/power. With an outer diameter of 180 millimeters, the PMI180 motor’s compact size simplifies machine integration. This is particularly important in small electric machinery in which the battery pack occupies most of the available space, leaving little room for motors, inverters, hydraulics, and other components. PMI180 offers 15% greater efficiency than AC induction motors. This higher efficiency extends the runtime of electric machinery or enables the use of a smaller, less expensive battery pack to achieve the same runtime. The robust design of the PMI180 enables the motor to be used in harsh conditions. The motor and connector feature an IP67 rating, providing protection from dust, dirt, and moisture ingress. The motor’s corrosion resistance has been validated in a 200-hour salt-spray test, offering extended protection. Combined, these features can increase the motor’s service life, even in extreme environments. “Editron has long been known for its high-voltage electrification solutions. Now we are strategically building out our low-voltage product lines to encompass 24- and 48-volt solutions,” said Eric Wang, Application Engineering and Portfolio Manager, Editron China, Danfoss Power Solutions. “PMI180 is built on advanced technology, a proven product development process, and decades of mature, global manufacturing and quality control, which means the motor is not only state of the art, but also highly reliable and built to last.” The Editron PMI180 motor features a rated power output of 7 kW at 48-volts DC. Its rated speed is 3,000 rpm and its maximum speed is 4,000 rpm. Rated torque is 22.5 Nm while maximum torque is 90 Nm. It features a standard gear pump interface for connection to pumps up to 16 cc at 240 bar. The PMI180 works with the EC-C48 inverter, which will be available in 2026. In addition to the PMI180, the ED-DT180 eDrive will be added to the Editron 48-volt portfolio. The eDrive is a propel solution for MEWPs and similar off-highway vehicles that integrates an electric motor, reduction gearbox, and electromagnetic brake in one compact package. Designed to be the most compact drive solution on the market, the eDrive simplifies machine integration while maximizing system efficiency and delivering a smoother driving experience for operators. The 48-volt system joins the 24-volt system launched in 2024. With the availability of PMI180 and DT180, original equipment manufacturers can create complete propel and work function systems for electric MEWPs. To learn more about the PMI180 electric motor, visit the Editron electric motors webpage, or visit Danfoss at Agritechnica in Hall 16, Booth A20. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

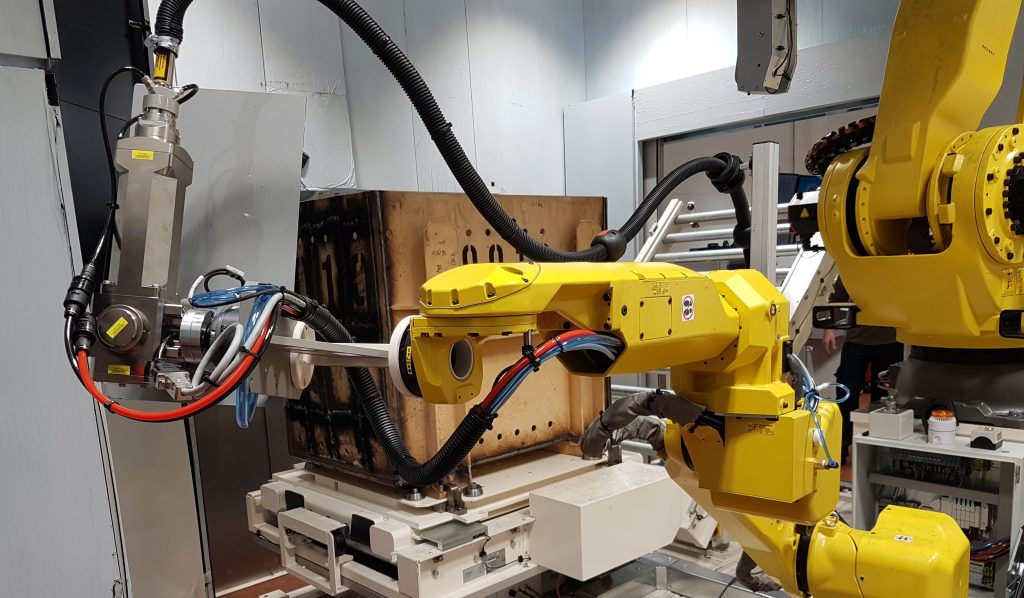

Fanuc Reliability Underpins Autonomous Laser Cutting Cell for Sellafield

FANUC’s ARC Mate 120iC and M-900iB/360 robots have played a starring role in a pioneering waste size reduction project as part of Sellafield’s ongoing decommissioning process. In a first-of-its-kind autonomous application designed and delivered by integrator Cyan Tec, the skip sorting and laser cutting cell has reduced the amount of space needed to store radioactive waste to a third of its original footprint. The cell has also slashed the time it takes to dismantle and repack radioactive skips from months to minutes, whilst eliminating human involvement in this hazardous operation. Background: a major pond cleanup operation Cleaning and decommissioning First Generation Magnox Storage Ponds (FGMSP) has become a major part of Sellafield’s ongoing nuclear cleanup efforts. To facilitate this, the skips that are stored in the ponds need to be removed. However, the limited availability of storage space for the skips once they have been extracted presents a challenge. With a track record in building turnkey automation, laser and robotics solutions for the nuclear industry, Cyan Tec was called upon to devise a solution for a localised size reduction process that would minimise the storage footprint of the removed skips. “Our idea was to cut up the skips so they would occupy less space – in this way, three skips could effectively be reduced to one,” explained Tony Jones, Managing Director of Cyan Tec. Previously, this type of work had always been performed manually, on the mistaken assumption that it was not possible to automate such a task. Operators wearing hazmat suits would use angle grinders to cut storage containers into pieces, but to limit exposure to radiation, they could only work for very short intervals. This meant that it would have taken approximately one month to break down each skip. Fraught with challenges However, automating this operation was no easy task, for a number of reasons. Firstly, the cell needed to fit into a very small area and, once operational, be completely autonomous, requiring no human intervention. Secondly, whilst the skips were all welded fabrications, their dimensions and their construction varied, and Cyan Tec had no visibility on the range of these dimensional differences. And thirdly, because of the considerations around safety and radioactivity, there were limited opportunities for commissioning and testing the system prior to installation. A safe, efficient and space-saving solution Cyan Tec designed and installed a full turnkey laser cutting and handling system to operate autonomously within a nuclear bunker. The entire cell is operated remotely, from a control room 100 metres away. The system was built at Cyan Tec’s Leicester facility and then installed at Sellafield and tested on non-radioactive skips before being put into action on contaminated skips under the supervision of project partner TKE Nuclear. At the heart of the system are two six-axis FANUC robots: a compact ARC Mate 120iC for cutting, and a heavy duty M-900iB/360 equipped with two interchangeable end-effectors: a scanning head and an electromagnet for handling the panels. When in scanning mode, the M-900iB builds a 3D image of the skip within the machine’s control system. MeshLab software compares the scanned skip with a reference skip, enabling the control system to adjust the parameters of the ARC Mate 120iC robot (equipped with a laser cutting head) and determine the optimum cutting pattern. The robots were selected above all else for their world-renowned reliability, which has been proven in accelerated life tests and is underpinned by an eight-year zero maintenance promise. “The cell had to be 100% reliable, as there was no opportunity for going in and fixing it if anything went wrong. That was why we chose technology that had already been proven in demanding industries. FANUC’s robots have a strong track record of working in demanding automotive plants with very high uptime figures, and demonstrate the highest reliability of any robot manufacturer,” said Tony. FANUC’s robots also aligned with Cyan Tec’s strategy of using commercially available technology wherever possible, as this was a test case for a COTS (Commercial Off The Shelf) project in an industry where an expensive bespoke approach has traditionally been the norm. Results: from one month to one hour The robotic cell was originally designed to size-reduce 50 skips of nuclear waste. It was so successful that it has since been used to process further skips of waste in a fraction of the time and with none of the health & safety implications of a manual operation. “This system has revolutionised the handling and size reduction of skips and demonstrated that a COTS approach can work in the nuclear industry,” said Tony. He continued: “It is incredible to think that by automating this task, we have been able to reduce the time it takes to cut down and repack a skip of waste from approximately one month to just 60 minutes. FANUC’s technology has been pivotal in achieving this outcome and our confidence in the solution we have delivered is rooted in our confidence in FANUC’s reliability and support.” Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

SGS Simplifies Multi-Market Compliance

SGS, the world’s leading testing, inspection and certification company, is reaching out to electrical and electronic (E&E) manufacturers to help them overcome the challenges of multi-market compliance through its Global Market Access (GMA) services. GMA services deliver a coordinated approach to meeting diverse regulatory requirements across safety, cybersecurity, energy efficiency and environmental standards, reducing complexity and accelerating time-to-market. Electrical and electronic devices, from smartphones and household appliances to industrial electronics, are now essential in daily life. Increasing reliance on these devices has prompted regulators worldwide to introduce stricter requirements covering safety, cybersecurity, sustainability and energy efficiency. Emerging technologies such as Wi-Fi 6E and 5G, combined with evolving energy efficiency standards in regions including the EU, China, India and Central America, make navigating multiple markets increasingly complex. Manufacturers often encounter differing requirements for testing, documentation, labeling and conformity marks, creating duplicated work and potential delays to market entry. SGS provides a single, streamlined solution to these challenges. By integrating testing, certification, documentation and labeling into a coordinated framework, manufacturers can ensure products meet national standards while avoiding repeated effort. SGS also delivers proactive insights on upcoming regulatory changes, enabling manufacturers to adapt designs, production plans and documentation before new rules come into effect. This approach simplifies market entry, reduces compliance costs and strengthens competitiveness. A wide range of E&E products are supported, including IT equipment, mobile devices, household appliances, luminaires, audio/video equipment, medical devices, photovoltaics, batteries, power supplies, power tools, machinery and automotive electronics. With its global network and deep local expertise, SGS helps manufacturers navigate complex regulatory landscapes efficiently, reduce risk and seize opportunities in new markets. SGS solutions SGS offers GMA services for a wide range of E&E products and components, including: With a global network and local expertise, SGS helps manufacturers meet diverse national standards, certification schemes and marking requirements. By combining technical testing, regulatory interpretation and market access support, SGS enables clients to improve efficiency, reduce risk and seize new opportunities. Find out more about SGS GMA services. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

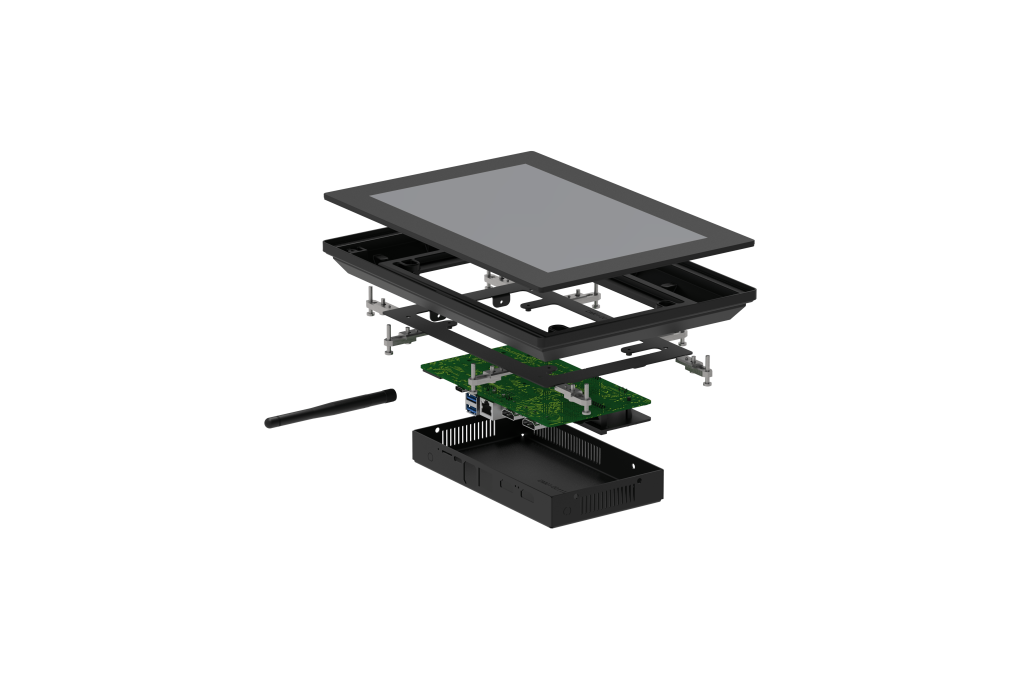

SECO Announces Early Access to the Pi Vision 10.1 CM5

SECO announced the opening of exclusive early access registration for the Pi Vision 10.1 CM5, the new industrial-grade Human-Machine Interface (HMI) powered by the Raspberry Pi Compute Module 5. This initiative offers OEMs, developers, and the Raspberry Pi community the opportunity to be among the first to experience SECO’s latest HMI platform — available in limited quantities and at a special introductory price of €239. From idea to industry: Raspberry Pi power in an industrial-grade design The Pi Vision 10.1 CM5 brings the power and flexibility of the Raspberry Pi Compute Module 5 to an industrial-grade, fully enclosed HMI platform. Designed for developers, makers, and OEMs ready to move from prototyping to professional deployment, it delivers the full Raspberry Pi experience — now in a rugged, production-ready form. Built from a solid aluminium structure and featuring a 10.1-inch multi-touch display with IP66 front protection, the Pi Vision 10.1 CM5 is engineered for durability in demanding environments. Every component, from the panel-mount enclosure to the high-brightness display, has been designed for continuous industrial operation. With native compatibility with Raspberry Pi OS and full support for Clea OS, SECO’s Yocto-based secure operating system, developers can choose between rapid prototyping on Raspberry Pi OS and enterprise-grade management with Clea OS. This flexibility makes Pi Vision 10.1 CM5 the perfect bridge between the Raspberry Pi community and industrial-scale applications. Key Features: Whether used as a development platform, a prototyping tool, or the core of a connected industrial device, Pi Vision 10.1 CM5 enables the Raspberry Pi community to go from idea to industry — without compromise. Powered by Clea OS: secure management and AI capabilities Running Clea OS, SECO’s Yocto-based operating system, Pi Vision 10.1 CM5 provides secure fleet management, real-time data processing, and AI-at-the-edge capabilities. Clea OS enables enterprises to manage connected devices, deploy and update applications seamlessly, and provides developers with an open, ready-to-use environment to accelerate innovation. “With Pi Vision 10.1, we translate the flexibility of Raspberry Pi into a professional, industrial-grade solution,” said Massimo Mauri, CEO of SECO. “This platform reflects our commitment to making connected and intelligent technologies more accessible to enterprises and developers, supporting faster innovation cycles and real-world applications.” Flexible across markets and applications By combining the Raspberry Pi ecosystem with SECO’s industrial reliability, the Pi Vision 10.1 CM5 enables rapid development of intelligent HMI solutions with long-term durability and broad software compatibility. Its flexibility makes it ideal for a wide range of applications, including: Availability The Pi Vision 10.1 CM5 is available in two configurations — 2 GB RAM / 16 GB eMMC and 8 GB RAM / 64 GB eMMC — both included in the limited launch offer. Early access registration is now open to secure priority availability of the first production units and the exclusive launch price: SECO: Pi Vision 10.1 CM5 Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Knorr-Bremse Acquires Duagon Group, Enhancing Growth of Global Rail Business

Knorr-Bremse, the global market and technology leader for braking systems and other safety-related rail and commercial vehicle systems, is building up its high-margin rail business internationally by acquiring the duagon Group. Headquartered in Dietikon, Switzerland, duagon is a leading supplier of hardware and software solutions for safety-related applications primarily in the railway industry and a multinational enterprise focused on Europe, North America, China, India and Australia. duagon is a good fit with Knorr-Bremse’s existing business – particularly in the field of safety-related electronics and software. Adding a further pillar to Knorr-Bremse’s operations, the acquisition will generate significant synergies in electronics, for example for braking and entrance systems – areas in which Knorr-Bremse already has leading expertise. What is more, duagon’s expertise and products will perfectly complement the global business of two Knorr-Bremse specialists: Selectron and KB Signaling. Given the increasing digitalization of trains and rail networks, the duagon acquisition will allow the two lines of business of railway electronics and rail signaling technology to maximize their profits in the fast-growing market for electronic, software-based, digital solutions for rail vehicles and rail signaling systems. For KB Signaling, which is taking its North American business global, duagon will provide the opportunity to harness additional growth worldwide. Marc Llistosella, Chief Executive Officer of Knorr-Bremse AG: “Our acquisition of duagon, a successful electronics supplier, demonstrates once again that we are strengthening our rail business, which will drive up profitable growth. More particularly, we are honing our technological expertise in the key areas railway electronics and rail signaling technology and are increasing the high-margin share of revenue in rail vehicles. The acquisition is a perfect fit with our BOOST strategy, giving us the opportunity to reinforce and build on our core competencies but also focus on high-profit lines of business. We would like to warmly welcome duagon’s international team and look forward to collaborating with them.” Dr. Nicolas Lange, member of the Executive Board of Knorr-Bremse AG with global responsibility for the Rail Division: “Safety, reliability, and efficiency are at the core of our DNA, which means that duagon is a perfect match for us. In duagon we are gaining an expert in specialist solutions for not just embedded electronics but also communications and software solutions for trains and train tracks. Above all, duagon’s platform solutions will allow us to increase the uniformity and scalability of our established solutions and to further improve the services we provide to our customers through digitalization. This acquisition will take Knorr-Bremse a big step closer to its goal of becoming a leading Tier 1 partner for the entire rail transport system, also with regard to electronic solutions.” Dr. Michael Goldbach, Chief Executive Officer of duagon: “With Knorr-Bremse, duagon gains a partner with whom we will strengthen and rapidly expand our position as a leading embedded electronics supplier in the rail market. We look forward to benefitting from Knorr-Bremse’s strengths and expertise, leveraging them in all business segments, and bringing our complementary expertise to the world of Knorr-Bremse. This will create an even broader range of opportunities for our customers and employees and ensure long-term stability and continuity.” Knorr-Bremse and the former owner DBAG Fund VII, a private equity fund advised by Deutsche Beteiligungs AG (DBAG), have signed a contract of sale to this effect. The closing is subject to the customary regulatory approvals. Safety-related products – a good match for Knorr-Bremse’s portfolio The acquisition will reinforce Knorr-Bremse’s commitment to the market segments for electronics, communications, and software solutions that perform safety-critical tasks in rail transport – areas experiencing higher-than-average growth. Digitalization in particular is driving up demand for highly advanced electronics and software. For example, duagon products are integrated into the on-board architecture of trains as well as the signaling technology along the railway lines. Among other things, they help to safely control train subsystems and process safety-related information, commands, and signals. These are profitable areas requiring sophisticated technology, with high barriers to market entry and involving longstanding customer relationships. Synergies and digital innovations Integrating duagon’s embedded electronics solutions into Knorr-Bremse’s portfolio will make it possible to tap into synergies over the long term, creating a basis for more uniform and holistic electronics platforms for numerous product groups worldwide. This integration will also enhance cost efficiency in research and development and increase competitiveness while fostering digital innovations such as remote monitoring and remote diagnostics for efficient rail operations and optimized maintenance. Established in 1995, duagon employs around 750 people across eight countries. The company achieved a compound annual growth rate of 15% between 2022 and 2025, a development Knorr-Bremse expects to be sustained over the coming years. Knorr-Bremse estimates that duagon will generate revenues of around Euros 175 million for 2026 with an operating EBIT margin of around 16% (excluding integration costs), which Knorr-Bremse plans to increase further in the coming years through significant revenue growth and cost potentials. In addition, Knorr-Bremse expects EBIT-effective run-rate synergies of Euros 5-10 million as of 2028. Customers of duagon include vehicle manufacturers, systems integrators, and infrastructure companies from the railway industry. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

SL Laser Advances Laser Projection Solutions with Customized Technologies for Industry Applications

SL Laser, a pioneer in laser projection technology since 1988, continues to set industry standards by providing customized solutions designed to meet diverse manufacturing and construction needs. Headquartered in Traunreut, Upper Bavaria, the company emphasizes its commitment to delivering reliable, adaptable, and industry-proven laser projection systems. With decades of experience, SL Laser’s laser projection systems support a broad range of industries, including automotive manufacturing, prefabrication, timber construction, and concrete element production. These systems are instrumental for accurate alignment, positioning, and visualization tasks across complex project workflows. SL Laser’s offerings include innovative options to accommodate challenging spatial configurations and budget considerations. While standard solutions often suffice, customer-specific adaptations are a core component of SL Laser’s approach, allowing for cost-effective and space-efficient integration. One notable development is utilizing independent laser projection units customized to individual project requirements, enabling flexible and scalable operations. A key advantage of SL Laser’s system architecture is utilizing rail-based setups that assist simultaneous work on multiple tools of varying sizes. This configuration allows operators to use two trolleys on the same large component, with each trolley functioning independently behind the scenes. Such modularity permits predefined work positions, minimizes needing multiple laser heads, and reduces overall investment costs. Besides, equipped with large screens and user-friendly interfaces, these systems deliver important real-time information, such as ply books, JPEG and PDF documentation, and operational remarks, to operators directly at the work site. In advanced automation and quality control, SL Laser has introduced solutions integrating sensors and software for real-time process monitoring. For instance, the company has developed a vacuum sensor-based compaction tool used in composite manufacturing. This system continuously displays the vacuum level in percentage and manages the process through an integrated countdown, enhancing process reliability and ensuring proper material compaction without relying solely on time-based parameters. Antonios Alexoudas, General Manager at SL Laser, emphasizes the company’s focus on developing adaptable solutions: “Our systems are designed to meet the specific needs of each project, whether it involves space constraints, cost considerations, or specialized process requirements. Flexibility is fundamental to our innovation process.” The company’s long-standing commitment to innovation stems from its recognition of the diverse challenges faced by modern production and construction environments. Customers often operate within complex spatial limitations or tight schedules, necessitating personalized solutions that maximize functionality without incurring unnecessary costs. Through modular system configurations, such as rail-mounted laser projections and portable units, SL Laser enables clients to optimize their workflows, improve accuracy, and reduce downtime. In addition to hardware solutions, SL Laser offers comprehensive software support, exemplified by its SL3D platform. This software provides real-time visualization and process monitoring, integrating data from sensors and project files to enhance operational control. The system’s compatibility with various file formats and its ability to display detailed instructions optimize project execution on-site. SL Laser’s product portfolio also incorporates specialized tools for specific industry segments. For example, in timber frame construction, laser systems assist in positioning prefabricated walls and trusses, ensuring precision and reducing assembly time. Similarly, in concrete manufacturing, laser projection systems assist accurate placement of formwork and reinforcement elements, contributing to higher quality and consistent product dimensions. The company’s emphasis on innovation and customization is reflected in its approach to customer challenges. Whether a project involves small tools requiring individual laser heads, large tools demanding integrated projection systems, or complex processing parameters like vacuum control, SL Laser develops solutions customized to each scenario. This level of adaptability distinguishes SL Laser as a leader in the laser projection industry. “Understanding the unique needs of each project allows us to deliver solutions that are both practical and efficient,” remarked Mr Alexoudas. “Our goal is to support industries in achieving precision and productivity through technological innovation.” As SL Laser continues to expand its portfolio, the company remains committed to delivering durable, reliable, and flexible laser projection systems. Through ongoing research and development, the organization aims to address emerging industry demands and maintain its position at the forefront of laser technology. For more information about SL Laser’s products and solutions, please visit the company’s website or contact their technical support team. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Say Goodbye to Cable Chaos. These New Hinges Do the Wiring for You!

CFM-PC hinge in UL-94 V0 self-extinguishing technopolymer, integrates the mechanical function of a standard hinge with the possibility to transmit electrical current from a jamb to the attached door. The UL-94 V0 certification confirms that the material, when subjected to a vertical burn test, extinguishes within 10 seconds without producing flaming drips. This ensures a high level of safety in case of accidental exposure to heat sources or open flames – an essential requirement for applications in industrial environments, laboratories, or portable equipment where protection against fire hazards is critical. Features and applications Standard executions are available in two versions: Features and applications Standard executions are available in two versions: Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News

Tunley Scientist to Speak at AER Live Webinar

Tunley Environmental has announced that its Biodiversity Lead and Senior Scientist, Dr Tara Garraty, will speak at an upcoming webinar hosted by Applied Ecological Resources (AER), part of the British Ecological Society, of which Tunley is a member. The session, titled “Biodiversity and Nature Reporting for Complex Global Supply Chains,” will take place on 15 October 2025 and will provide an overview of how biodiversity and nature-related impacts can be understood and reported across global supply chains. With biodiversity loss recognised as both an ecological emergency and a business risk, organisations are under growing pressure to account for their impacts on nature in transparent and science-led ways. The workshop will explore the evolving landscape of biodiversity and nature reporting, including emerging frameworks and the challenges of applying them within complex international supply chains. Dr Garraty will be joined by Benedicta Bakpa, Head of ESG at pharmaceutical company Bespak, who will share industry insights on the opportunities and practical considerations of integrating biodiversity into corporate sustainability strategies. Dr Garraty said: “I’m looking forward to sharing how businesses can turn complex biodiversity data into clear, practical actions. We’re already seeing real progress, like in our collaboration with Bespak, where companies are taking meaningful steps to protect nature and build resilient supply chains”. The event will be valuable for ecologists, environmental managers, sustainability professionals and supply chain specialists seeking to strengthen their understanding of biodiversity reporting and its role in shaping a nature-positive future. To register for this free webinar, please visit this page. Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News