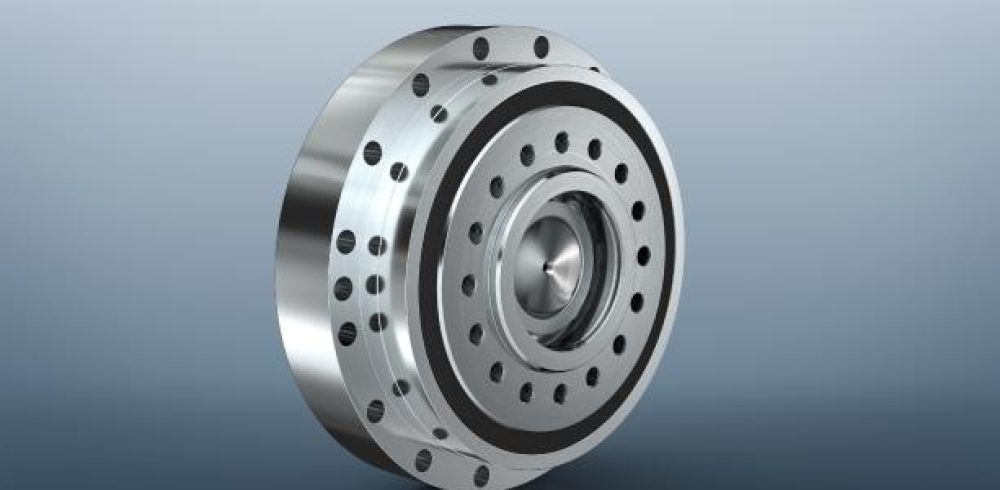

In 2015 Sumitomo Drive Technologies designed the precision gearbox series F4CF-D. Then, in 2017 the modular system was expanded to facilitate the addition of compatible components, i.e. motor mounting capability. This year the series has been further developed as the F4CF-DA series and was launched on the market with Sumitomo was presenting this latest, further developed, generation at SPS connect which, due to Coronavirus conditions took place exclusively virtual.

Based on the proven Fine Cyclo Technology – the basis of all Sumitomo Precision Gears – this new development now offers several significant advantages. The most important innovation – when compared to competitor units – is the significantly increased torque per unit size. The number of sizes in the series line up has also been significantly expanded in response to customer demand for more individuality and new sizes have been developed accordingly.The DA series gearboxes are now approx. 8% smaller in diameter and 5% shorter in length. Despite this reduction in size, performance has been increased by approx. 20% across the range, giving a triple benefit. More power, less space and conversely less weight.

The noise levels of the DA series have also been optimised and significantly reduced. This is an important factor when people are working near the drive applications, as for example in the medical field.

With these products, Sumitomo Drive Technologies also aim to expand the demands of major customers in the fields of robotics, machine tools, medical device technology and food & beverage applications. The experience gained from long established and existing applications has contributed significantly to the original design of the DA series and subsequent product developments. For large quantities the price/performance ratio has a profound affect where, the single-stage gearboxes of the DA series offer significantly lower manufacturing costs when compared to standard two-stage gearboxes, of the same torque class.

Plug & Play Gearboxes

All sizes of the DA series can be easily integrated into systems. The motor shaft is connected to the gear unit by way of a clamping ring which offers a friction connection eliminating the necessity for the customer to adapt the motor connection to suit. For each of the DA series sizes, the connection of several motor shaft diameters is possible, allowing the use of motors from many different manufacturers. The connection geometry does not require a complex installation, nor does it require an adjustment of the drive shaft by the customer. Sumitomo are therefore able to offer a remarkably simple installation of both the gearbox and the motor. Thanks to the partnership with the motor specialist Lafert, Sumitomo can also offer servo motors and controllers from a single source.

Sumitomo entered a technical alliance with Lorenz Braren in 1938. Since then, his invention has formed the basis for Sumitomo’s most important products and their further developments on the market and still confirms the company as a technology leader today, as cyclo gears are successfully used worldwide, for example in industrial robots and transfer machines. The newly developed backlash-free DA series has three smooth cycloid disks arranged in a balanced system.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News