SL Laser has been a pioneer in the field of laser projection, providing essential tools for production and assembly since the early days of this technology.

With thousands of installed laser systems worldwide, SL Laser’s projectors significantly enhance and streamline workflows across various industries. The use of laser projectors for projecting edges, drill holes, and contours has become a standard practice in many industrial and craft businesses. Instead of the labor-intensive process of preparing expensive templates, the ProDirector 7 projects all necessary templates directly onto the workpiece or even the work table at the push of a button. This device can effortlessly switch to the next work step or layer, allowing for rapid, precise, and safe continuation of tasks. Work time reductions of 25% or more are typical, coupled with unmatched precision that not only enhances product quality but also lowers error rates within companies. The tedious tasks of measuring and transferring plans to workpieces are eliminated, reducing the likelihood of mistakes.

Furthermore, many quality management tasks can be simplified, as individual elements can be highlighted step by step for easy verification. This time-saving approach means that various positions no longer need to be identified and re-measured, and the sampling inspection of complex components is significantly accelerated with the aid of laser projection. In most cases, the data required for the laser projector is easily converted from CAD software and directly transmitted to the projector. The virtually projected templates are as precise as they are easy on the eyes, contingent upon the accurate calibration of the workspace and the correct positioning of the projector.

In large facilities, such as woodworking in furniture production, these systems serve as setup aids for CNC milling machines, ensuring that all suction cups remain intact and workpieces are perfectly positioned. In other sectors, such as timber frame construction and the processing of laminated beams, components are no longer manually aligned. Instead, they are projected directly from CAD data, allowing for rapid and reliable positioning of nails, slats, or laminated beds. This method eliminates the need for templates and reduces the necessity for extensive corrections, resulting in fewer errors, decreased material waste, and significantly increased work speed.

In aerospace manufacturing, a network of laser projectors is often employed, all interconnected for enhanced efficiency. Many companies also utilize a system that allows the laser projector to be moved along a rail system suspended from the ceiling. In such instances, the various positions are pre-saved in the system, enabling seamless transitions to the next work step at different ends of the assembly line. The motivation of the workforce sees a considerable boost with the implementation of such a projector. With an accuracy of ± 0.35 millimeters, satisfactory precision is achieved even in the assembly of helicopter cockpits, where numerous switches and buttons must be installed and mounted with precision. Depending on workplace conditions, projections can be made using green or red laser beams.

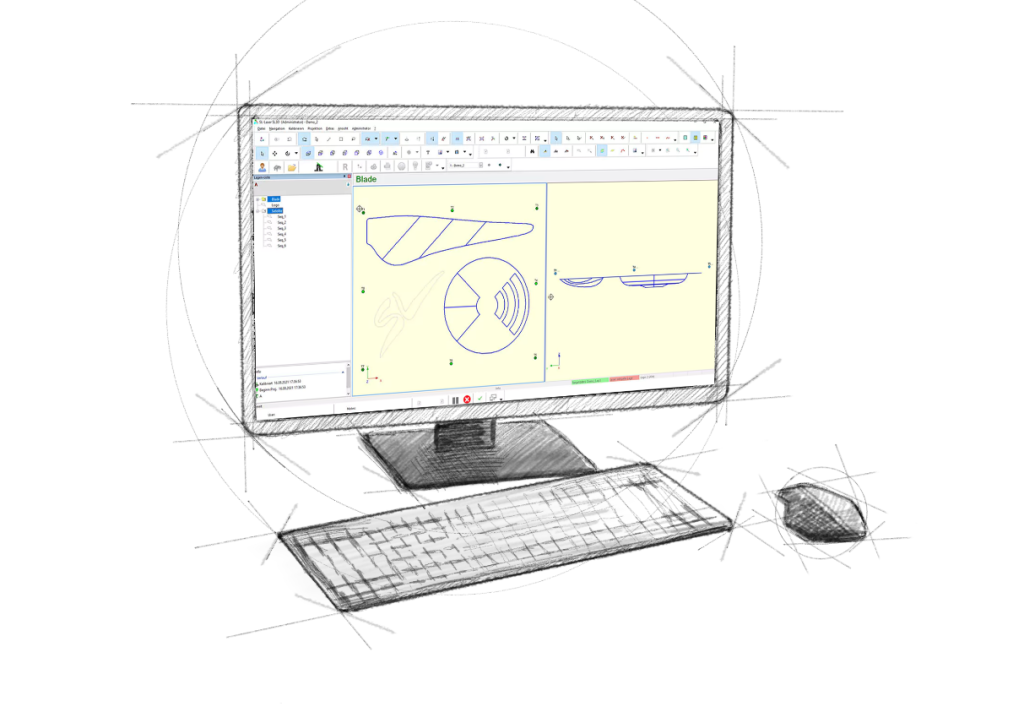

The next evolution in the use of a laser projector involves working with sophisticated software. Particularly in the case of complex components and prototypes, 3D CAD data is utilized to create a cohesive three-dimensional overall impression. To facilitate this, SL Laser has developed specialized software, such as for 3D composite applications. SL3D allows for seamless interaction with 3D data as well as multiple projectors. It imports 3D CAD data from all common formats, including STEP, IGES, DXF, or even XML. The conversion of 3D data enables a graphical 3D view in the projection, with image content displayed in up to four windows simultaneously to match the projection. In addition to graphical images and projections, PDF or JPG files that describe the respective work process can also be displayed, with the appropriate projector automatically selected for each layer being processed.

SL Laser has consistently focused on ensuring that its laser projectors seamlessly integrate into existing workflows and processes. This same approach is applied in the development of user software and all training courses for customers. This philosophy has allowed SL Laser to successfully launch its products globally since the 1990s.

Positioning lasers (line, cross, circular and other optics) from SL Laser form an essential part of the product portfolio alongside the worldwide distribution of laser projectors and measurement systems. For decades, positioning lasers have become indispensable in craft and industrial production.

The line laser from SL Laser, along with the cross laser and circle laser, constitutes the basic equipment for precise positioning tasks. A line laser from SL Laser guarantees maximum precision, robustness, and impressive range. Whether for positioning tools or aligning components and workpieces, a professional line laser accelerates and simplifies work processes while reducing error rates. With a line laser from SL Laser, saw work in woodworking is as precise as the display of cutting lines in the textile industry, as well as for marking fold edges.

The cross laser allows for the determination of reference points or markings for various processing methods. It is also crucial for the exact positioning of machines and tools. In woodworking, this is particularly important for determining the positions of suction cups on CNC machining centers. In furniture construction or mechanical engineering, cross line lasers establish precise markings for millimeter-accurate drilling, stops, or the adjustment of workpieces.

Both cross lasers and line lasers are available as standard products. However, we frequently manufacture custom solutions tailored to meet the specific needs and requirements of our clients. Even with standard models, we offer various performance classes designed for different distances and display sizes. The robust housing of our cross lasers, line lasers, and other positioning lasers are electrically insulated. Upon request, they can be supplied with a power supply and mounting bracket. SL positioning lasers can be focused to accommodate varying distances. Depending on your requirements, SL Laser offers positioning lasers in different power levels. Typically, green lasers are advantageous due to their better visibility to the human eye. However, environmental factors also play a significant role; under certain lighting conditions, a red line laser may perform even better. With a positioning laser from SL Laser, you are investing in a precision instrument that is inherently designed to withstand all challenges. Durability, range, precision, and usability have been optimized and perfected over decades.

SL Laser systems are utilized worldwide in literally thousands of industrial and craft businesses. If you would like to learn more about how such lasers can be implemented in your company, contact SL Laser.

SL Laser – your reliable partner for laser applications for over 35 years.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News