Tooling plays a crucial role in the precision, quality, and efficiency of injection moulded components. Its success depends on specialist expertise, smart material choices, and reliable access to technical support.

Business Development Manager at MGS Technical Plastics Chloe Maine explores how processors can reduce their tooling risks and shares tips on how to ensure the highest quality tooling support.

- How does a mould tool work?

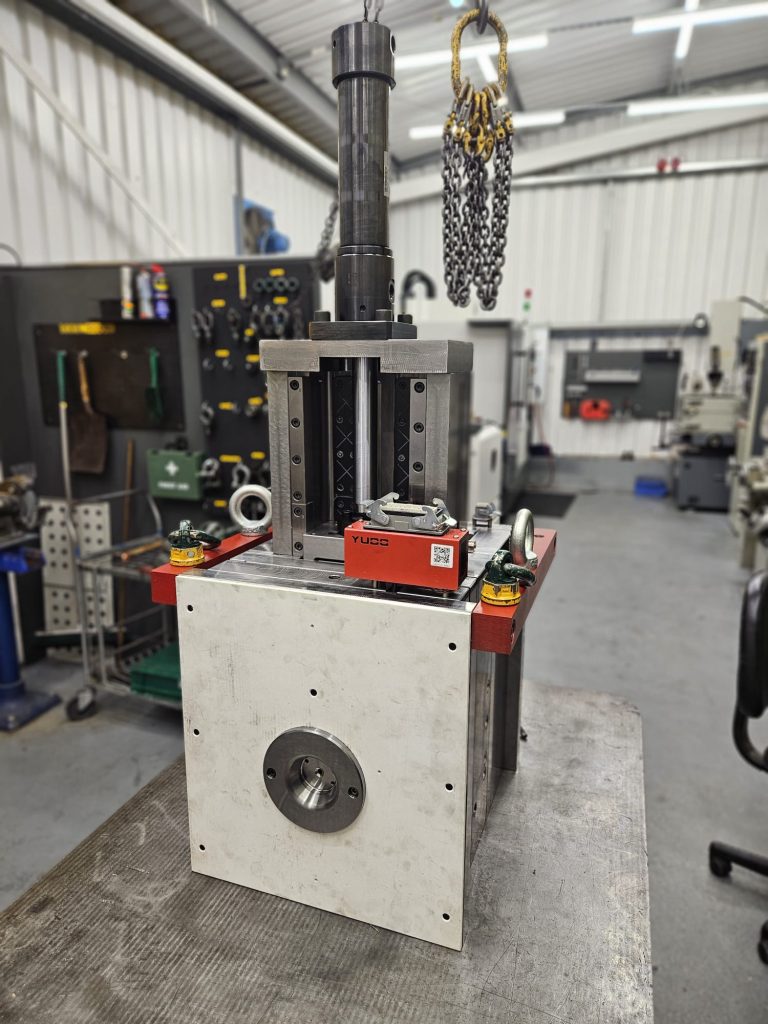

A mould tool is a high precision, engineered assembly that manufactures complex parts in high volumes by forming molten plastic into specific shapes. Each mould tool is custom designed for a specific part or product family to meet detailed design specifications. Typically comprising two primary halves: cavity (A-side) and core (B-side). When clamped together in a moulding machine, these two halves form a hollow space – or cavity- that precisely replicates the product shape.

Additionally, the mould tool performs several critical roles during the moulding cycle. It manages the controlled flow and distribution of molten material into the cavity via sprues, runners and gates. It incorporates thermal regulation systems, such as internal cooling channels, to precisely control the rate of material solidification. Once the part has cooled and solidified, the tool uses mechanisms like ejector pins, plates, or even custom lifters to eject parts cleanly and reliably.

- What is a multi-cavity tool?

Mould tools vary significantly in complexity depending on the application. One of the most efficient formats for high-volume production is the multi-cavity tool. Unlike a single-cavity tool that produces one part per cycle, a multi-cavity mould includes multiple identical cavities within the same tool. This allows several parts to be formed simultaneously during each cycle. The benefits include increased throughput, reduced costs per unit, and improved manufacturing efficiency.

- How does a family tool differ?

Similar in format, a family tool instead produces different parts simultaneously within the same mould. Each cavity in a family tool corresponds to a distinct component – often parts that will be assembled together later, e.g. a container and its lid, or various components of a single product.

Family tools offer excellent efficiency for assembly-based production lines, reducing handling time and tooling costs. However, they present greater design and process challenges due to varying sizes, volumes, and cooling characteristics. Careful balance must be achieved to ensure all parts fill and cool properly within the same cycle. Gates, runner sizing, and cooling circuits must be meticulously designed to avoid inconsistencies in quality or cycle time.

- What are the benefits of each?

Single-cavity tools provide high precision and are ideal for large, complex parts or low-volume runs, including prototyping. Multi-cavity tools instead increase output and efficiency by producing multiple identical parts per cycle, lowering costs. Family tools produce different parts in one cycle, reducing tooling and handling costs while streamlining production and ensuring part compatibility.

- Will tooling material affect the quality of moulded parts?

Steel types used play a crucial role in the quality, consistency, and longevity of the parts the mould tool produces. Factors such as durability, surface finish, thermal conductivity, corrosion resistance, and machinability all depend on the steel grade selected. High-quality mould steel ensures precise cavity dimensions, smooth surface finishes, faster cooling times, and longer tool life.

- Is it more cost efficient to use external companies to manufacturer tools?

Choosing in-house or outsourced toolmaking depends on the scale, complexity, and specific requirements of each project. For larger-scale projects or when multiple tools are needed, outsourcing can often be more cost-effective and time-efficient. However, when precision and close control are critical, managing the toolmaking process in-house helps to maintain quality, flexibility, and speed.

In either case and regardless of where they are built, applying Design for Manufacture (DFM) principles early in the development process is essential for precision and efficiency, maintainability and scalability.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News