Rubix, a leading European distributor of industrial products and services, has announced the latest results of its industry health indicator ‘The Uptime Index’.

Standing at 70, down four points on June 2025, the Index reveals a dip in confidence around the factors affecting uptime and long-term performance.

The latest figures – based on a survey of 1,300 manufacturing businesses across Europe – suggest manufacturers are under pressure but maintaining output with fewer resources; leaning on smarter data, tighter maintenance planning, and stronger supplier relationships.

People and investment remain the weak links, with a shortage of skilled staff and short-term ROI focus constraining long-term efficiency gains.

Larger manufacturers continue to show greater resilience, due to their scale, capital, and established supplier networks. They are also emerging as the AI front-runners, with the scale, data maturity, innovation culture, and capital required to integrate the technology into everyday operations, rather than treat it as a side project.

Commenting on the latest wave of findings, David Cullern, Group VP Key Accounts at Rubix, said: “The story of November 2025 is one of constraint. High tariffs, trade difficulties, rising energy costs, skills shortages and competition from Asia are all piling pressure on the budgets of European manufacturers. Companies are being asked to achieve more with fewer resources.”

The Uptime Index is part of a continuing initiative to monitor and understand shifts in performance, confidence and capability across European manufacturing.

AI in manufacturing: proven performers, the next big thing and unsung essentials

Alongside the November Index, Rubix took a deeper look into how Artificial Intelligence (AI) could help manufacturers improve performance.

It revealed the biggest manufacturers already have AI at work on the factory floor – although just 1 in 4 companies acknowledge they expect it to have a ‘significant impact’ on improving uptime in the next year.

Cullern continued: “The wider adoption of AI presents a solution to many of the challenges facing manufacturers today. And much of it can be achieved by working smarter with existing systems.

“From quick wins to more targeted long-term investments, AI has the potential to help businesses spot production line problems before they arise, improve their efficiency and maintain uptime with growing confidence in the face of constraints.”

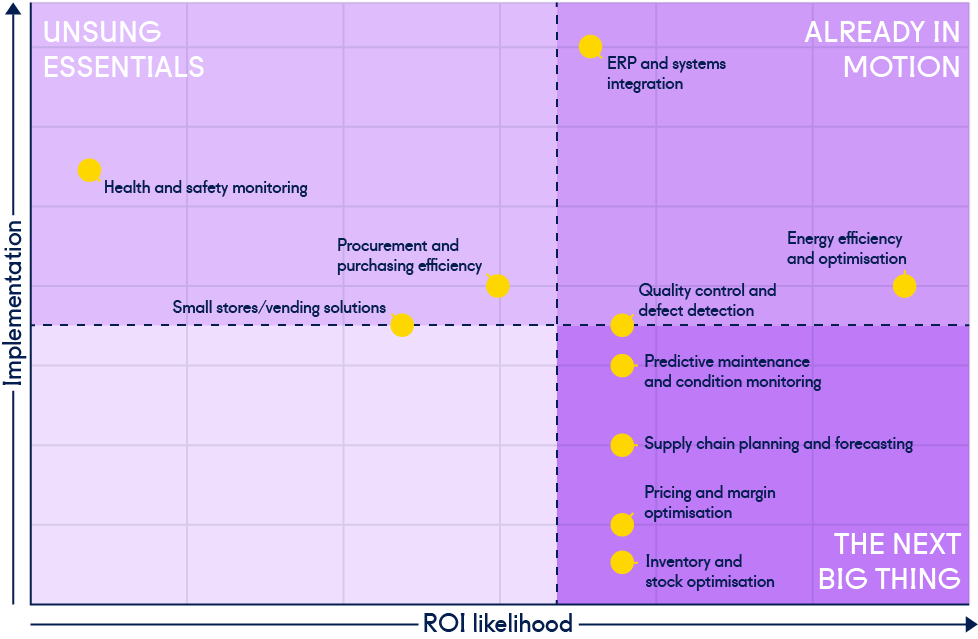

Three clear patterns emerged when mapping AI implementation progress against perceived ROI:

- “proven performers” already showing measurable payback, such as energy optimisation tools

- “next big thing” candidates for near-term investment, including predictive maintenance and supply chain forecasting

- “unsung essentials”, like health and safety monitoring, where there is a need to articulate value beyond compliance.

Culllern added: “The manufacturers that move first to adopt the right technologies will gain an advantage over competitors while improving uptime. Businesses that fail to spot and adopt the best use cases of AI risk falling behind their competitors in terms of efficiency and minimising downtime across their production lines.”

Whitepaper: Progress under pressure: How manufacturers are maintaining performance – and where AI is starting to make an impact

To support the Uptime Index, Rubix has published its latest whitepaper, informed by further insight, including in-depth customer interviews, to provide deeper analysis of industry needs and opportunities concerning uptime and manufacturing performance.

“Progress under pressure: How manufacturers are maintaining performance – and where AI is starting to make an impact” highlights how European manufacturers are grappling with squeezed margins, tighter credit, and longer lead times – conditions that are forcing tough choices on where to invest time, money and people.

It also explores the varying degrees to which companies are integrating AI, acknowledging how adopting any new technology can be challenging, while warning that in a world where change is accelerating rapidly, businesses that do nothing risk falling behind.

To view the full findings, visit: www.rubix.com/uptimeindex

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News