Precision, flexibility and durability are critical in industrial sectors to optimise operations while maintaining safety and value. One component that remains constant is friction joints, which are valuable for connecting components in situations where traditional methods may not be practical.

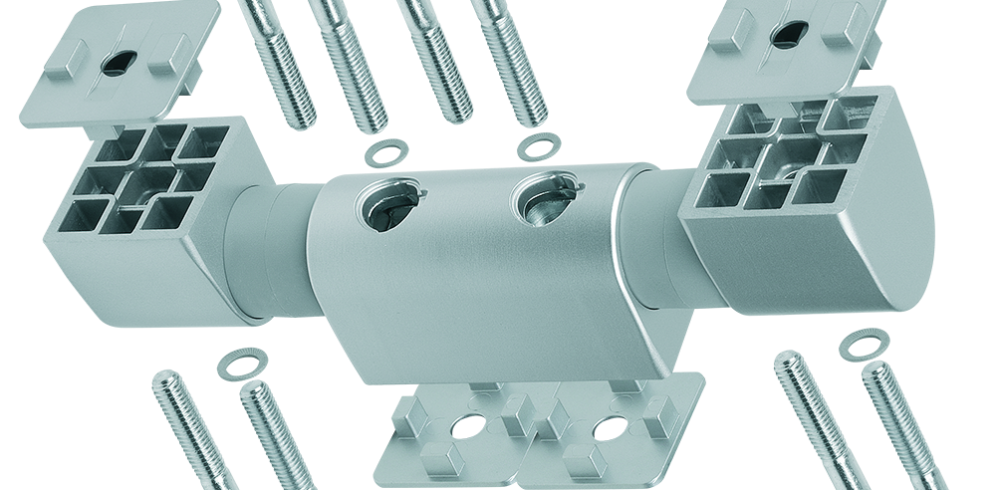

To address these evolving demands, global standard components manufacturer norelem, has launched a new series of friction joints (10271) designed to meet the unique requirements of various industries, providing essential benefits that cater to a wide range of customers.

Marcus Schneck, CEO of norelem, said: “One of the key benefits of our friction joints for customers is their ability to deliver precise and adjustable resistance to motion. This capability is crucial in maintaining stable positioning and control in mechanical systems. It is especially useful in automotive assembly lines requiring frequent adjustments and high precision.”

Likewise, the stability of these joints ensures that tools and workpieces remain securely in place, significantly enhancing productivity and minimising downtime by reducing the need for constant repositioning.

Schneck continued, “Our friction joints also offer versatility with their adjustable settings and feature a set screw that allows for nearly continuous adjustment of friction from light to heavy.

“These joints are particularly valuable in the aerospace industry, where different torque levels are necessary for various stages of assembly and testing. This feature enables fine-tuned adjustments, ensuring accuracy and efficiency while meeting stringent quality standards.”

In addition to their versatility, the flexibility in mounting options further broadens the appeal of friction joints, which are designed to fit standard aluminium profiles, allowing them to be installed in multiple positionings, making them an ideal choice for diverse applications.

For example, in electronics manufacturing, the joints support the creation of adjustable workstations that cater to different assembly and ergonomic requirements. This optimises workspace configuration and enhances operator comfort, leading to improved productivity and reduced injury risks.

In environments where workers handle heavy or complex tools, such as consumer goods production, The friction joint’s ability to position axes vertically and horizontally allows for ergonomic adjustments tailored to various body sizes and working postures, reducing physical strain and increasing overall efficiency.

When it comes to heavy-duty applications, such as industrial machinery, norelem’s friction joints can handle a fixed torque of up to 15 newton metres. This strong clamping technology maintains consistent friction over a long lifespan, reducing maintenance requirements and improving operational reliability.

Finally, Schneck said, “By offering customisable and adjustable solutions, norelem’s friction joints empower customers across various industries to improve productivity, comfort and long-term performance by tapping into its versatility across a range of applications.

“Whether you’re working in automotive, aerospace, electronics or beyond, friction joints provide the precision, flexibility, versatility and durability needed to meet the challenges of modern industry.”

For more information about norelem’s friction joints and to explore how they can enhance your specific applications, visit norelem’s website.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News