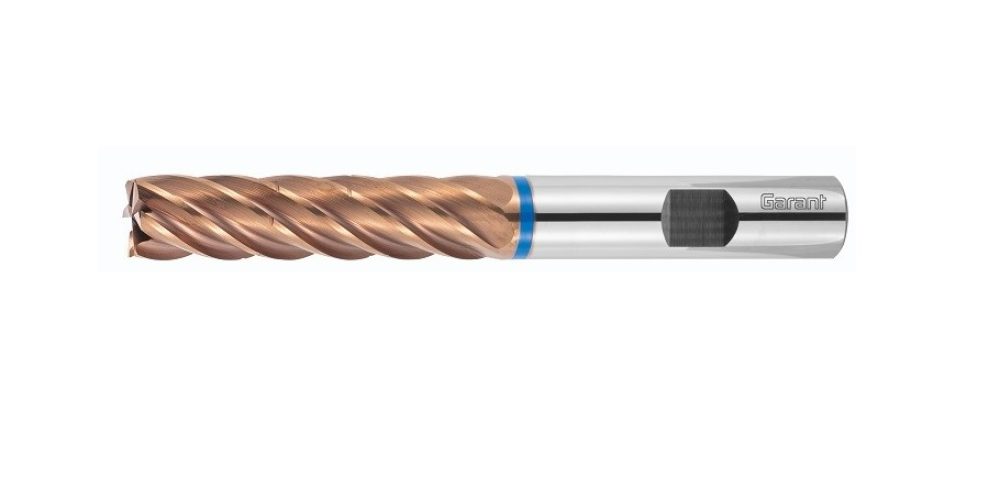

With the GARANT Master INOX TPC solid carbide milling cutter, the Hoffmann Group has brought a new specialist tool for machining stainless steels and duplex steels to the market. The high-performance milling cutter has shown itself to be very powerful even when machining internal profiles and has demonstrated extremely high process reliability in automated environments. At the same time, it has achieved high volumes of metal removal compared to similar tools and a particularly long tool life. The milling cutter can be resharpened multiple times and thus permits particularly economical and sustainable tooling.

In the trochoidal milling process (TPC) the tool advances in small elliptical circles. This allows the full cutting depth to be machined at high cutting speeds. Lower cutting forces are generated and the stresses on the tool are maintained evenly – which reduces the rate of wear. This to some extent is the reason why the tool life of TPC milling cutters exhibits up to a tenfold increase compared to conventional tools. The new GARANT Master INOX TPC combines these advantages with an optimised micrograin carbide substrate which makes it extremely resistant to flexural breakage and ensures a long tool life, even when performing high-performance cutting of duplex steels. With its optimised number and positioning of chip separators, it produces short chips and exhibits a minimum of potential wear points, whilst the enlarged flutes provide sufficient space to allow reliable clearance of chips. In addition, thanks to a reduced helix angle, the pull-out forces andhence the load on the tool arbor and the machine spindle are reduced, which further improves process reliability. A gain in stability at long overhangs (4xD and 5xD versions) is achieved by an optimised core diameter profile.

The new GARANT Master INOX TPC solid carbide milling cutter requires the use of high-performance CAM software and a modern machine control system, since the milling path must be continually recalculated.

The GARANT Master product range was started by the Hoffmann Group in 2015 with the aim of providing particularly powerful and reliable tools for high-performance cutting. Since then, GARANT Master tools have opened up new performance classes, including the GARANT Master Steel HPC milling cutter, the GARANT Master Steel Feed and Speed solid carbide drills, and the GARANT Master Steel Deep solid carbide deep hole drill. The product range now comprises a wide range of high-performance tools for applications such as drilling, milling and thread tapping in various materials, including steel, aluminium and stainless steel.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News