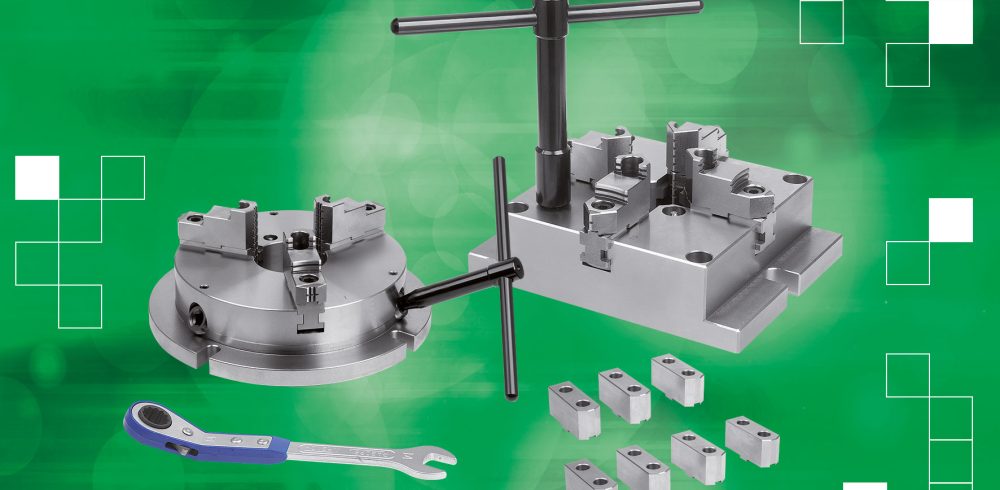

Stationary jaw chucks are an essential tool in manufacturing, particularly in drilling and milling environments. Enabling workpieces to be stably fastened, norelem’s range includes 3-jaw and 4-jaw chucks made of steel for optimum performance.

Providing stability to the workpiece, parts being machined can be clamped between clamping jaws, while the drill chuck holds the tool in place – a factor which is particularly important for fast-moving machines to ensure precision and safety.

The 3-jaw chuck from norelem has three clamping jaws, enabling round, triangular or hexagonal workpieces to be securely clamped in the lathe. Alternatively, the 4-jaw chuck can be used to clamp a variety of other shapes, including four, eight and twelve sided workpieces.

The flexible arrangement of the clamping jaws in hard and soft design allows workpieces of different sizes and shapes to be easily clamped from the inside or outside using a hexagonal wrench. To create a synchronous movement of the clamping jaws and ensure consistent clamping force, a slewing ring located in the chuck and the rotational movement of the threaded spindle, creates a moveable base for the jaws to operate. To maintain reliable function and clamping force, regular lubrication of the components is essential via the optimally positioned lubrication system.

The advantages of norelem jaw chucks

Quick and easy to operate, norelem jaw chucks have a flat design and a large through-hole for clamping bar material. The base body of the jaw chucks is made of ground steel, as are the clamping jaws which use hardened and ground steel, enabling a repeatability of 0.02mm in centric clamping. Soft jaws can also be screwed onto the base jaws to generate individual clamping contours and diameters.

Stationary 3-jaw chucks are available in four different diameters from 220 to 370mm and can achieve a clamping force of up to 44kN. Stationary 4-jaw chucks are available in four different sizes with a width of 215 to 38mm, with a clamping force of up to 25kN.

Every success starts with an idea. That’s why norelem supports designers and technicians in mechanical and plant engineering in achieving their goals, with the right solutions for every job available in THE BIG GREEN BOOK – norelem’s unique and easy-to-use product catalogue. With thousands of products immediately available, professionals can save time and underpin the optimisation of processes.

As an established industry insider, norelem is committed to promoting young talent with the norelem ACADEMY. So that the designers of tomorrow can really get off to a flying start.

In addition, the norelem ACADEMY offers technical training, seminars and product training.

You can see norelem’s products up close or talk to its dedicated product team at Subcon 2024 from the 5th – 6th of June at the NEC in Birmingham on stand A61.

To find out more, visit the norelem website.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News