5-axis expertise, freely scalable automation, and integrated manufacturing processes – at this year’s Open House in Pfronten, DMG MORI is once again shaping the future of production – live from January 26 to 30 with a focus on the D-A-CH region and from February 2 to 6, 2026, for all international guests. During these two weeks, trade visitors from all over the world will experience solution-oriented machine concepts for companies of all sizes up close. The focus will be on industry-specific applications from the aviation & space, data & semiconductor, and die & mold sectors. “We combine future-proof machining technologies with integrated processes, automation, digital solutions, and reliable service throughout the entire machine life cycle. In this way, we demonstrate that modern manufacturing does not have to be complex – if technologies are conceived holistically, implemented modularly, and tailored to the requirements of especially small and medium-sized enterprises,” says Cornelius Nöß, Chief Managing Director of DMG MORI Pfronten, about the range of services. Another highlight at the Pfronten site is the opening of the new 4,500 m² training center, where the next generation of young talent will be nurtured. Technology seminars on Machining Transformation (MX) and the associated manufacturing solutions round off the Open House exhibition program.

Innovative new developments across the entire portfolio

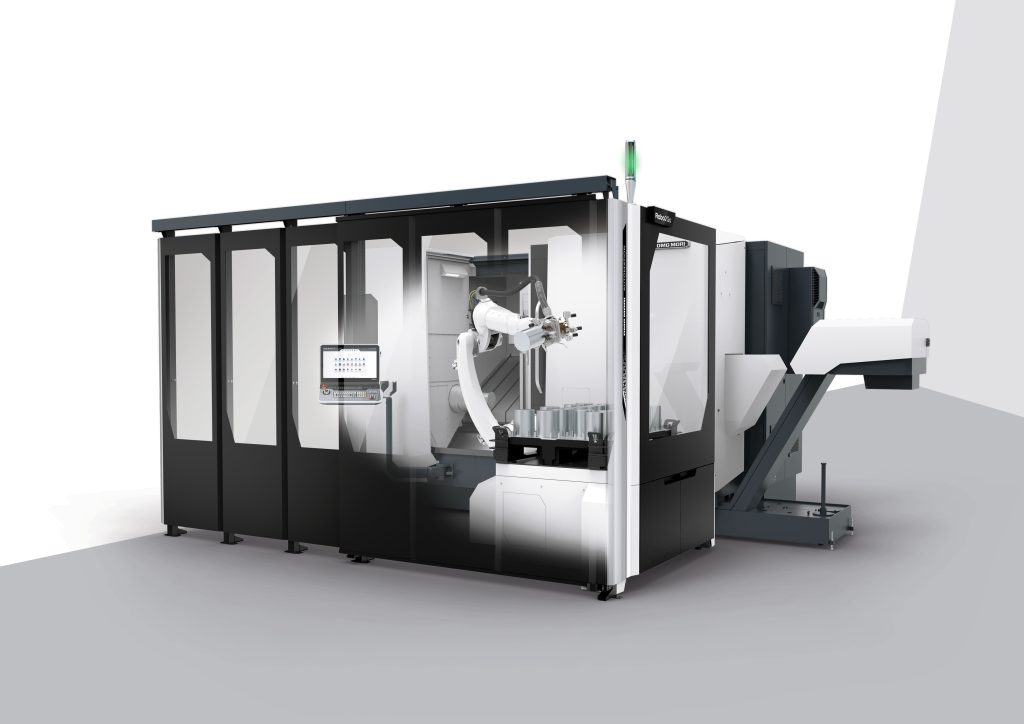

The basis for the comprehensive range of solutions is an extensive range of machines for a wide variety of metalworking processes. DMG MORI will be showcasing over 40 machines and more than 20 automation solutions across an area of 4,500 m² during its Open House. The focus will be on three world premieres: in universal turning, the machine tool manufacturer will be presenting the CTX 450 4A. In the field of additive manufacturing by powder nozzle DMG MORI will present the second generation of the DMU 65 H monoBLOCK 5-axis horizontal machining center and the LASERTEC 65 DED hybrid. The Robo2Go 3rd generation will be presented as an innovation in the automation range.

Technology expertise for integrated and scalable production

The world premieres exemplify the path that DMG MORI is consistently pursuing in the further development of its product range. “Advanced 5-axis technologies and fully integrated automation solutions are the key to a long-term competitive future in increasingly globalized markets,” explains Cornelius Nöß with regard to the exhibition spectrum. The manufacturing solutions on display guarantee productivity, process reliability, and exceptional quality. DMG MORI’s extensive machine and automation portfolio offers maximum flexibility to meet all the requirements of modern production – be it single-part or large-scale series production. The manufacturer is demonstrating the entire range of available technologies in several exhibition areas – from flexible 5-axis solutions and powerful turn-mill machines for 6-sided complete machining to advanced technologies. The focus here is on additive manufacturing on LASERTEC DED hybrid and LASERTEC SLM machines, as well as the ULTRASONIC models and vertical multi-process grinding machines from the Vertical Mate series. An automation area demonstrates the use of driverless transport systems. With the autonomous handling of machine pallets, material pallets, chip carts, and tools, forward-looking AMR models impressively demonstrate how entire production processes on the shop floor can be organized without human intervention.

Quality-oriented, efficient, and sustainable through Machine Transformation (MX)

With Machining Transformation (MX), DMG MORI is laying the foundation for the manufacturing of the future. Consistent process integration, flexible automation solutions, and fully digitized processes result in shorter setup and cycle times, more precise machining results, and more resource-efficient production. The technological backbone of this concept is formed by turn &mill centers, mill-turn machines, and horizontal machining centers, which integrate additional work steps into a single clamping. At the same time, they offer a high level of connectivity to make processes more efficient with the help of digital solutions – covering work preparation, NC programming and quality control. Cornelius Nöß explains the added value of the concept: “With Machining Transformation (MX), DMG MORI is pursuing a holistic approach that streamlines processes while increasing productivity and efficiency.” This has a particular impact on Green Transformation (GX). For both ecological and economic reasons, the shift toward sustainable manufacturing is becoming an increasingly decisive competitive factor.

A strong partner for companies of all sizes

Industry leaders and the entire supply industry depend on reliable manufacturing solutions to remain competitive in the global marketplace. Working closely with its customers, DMG MORI designs customized manufacturing solutions that meet the increasing demands for quality, efficiency, and productivity. Future-proof CNC machines are essential. DMG MORI emphasizes this above all with its world premieres: The CTX 450 4A offers optimal connectivity for networked production, while the 5-axis DMU 65 H monoBLOCK enables a high degree of process integration and efficient processes in a single setup. Small and medium-sized companies in particular benefit from access to well-thought-out concepts with flexible and scalable automation – also available as easy-to-retrofit options if required. The new Robo2Go 3rd generation is just as good an example as the proven PH Cell solutions for modular pallet handling. The partnership with customers extends across the entire machine life cycle, adds Cornelius Nöß: “From consulting to installation and training to responsive service, DMG MORI guarantees comprehensive and customer-oriented support.” After all, reliable production is the basis for healthy growth.

Young talents for innovation

The future begins with the people who shape it. Practical knowledge transfer in machine tool manufacturing is therefore an important prerequisite for future generations. After all, the next generation will be tasked with driving innovation forward in the future. While the DMG MORI Academy has been supporting the promotion of young talent for many years in cooperationwith training workshops and educational institutions, the machine tool manufacturer also attaches great importance to an optimal learning environment within its own company. DMG MORI is underlining this with its new 4,500 m² training center in Pfronten, which will open during the Open House Pfronten. “With this modern training center, we are creating space for ideas, enthusiasm for technology, and first-class training,” says Cornelius Nöß. Around 150 apprentices, trainees, and dual students will be prepared here for the challenges of Industry 4.0. With innovative technology and practical learning environments, DMG MORI wants to pass on a genuine enthusiasm for mechanical engineering to the next generation: “Because they are key shapers of the future. They bring new ways of thinking, digital skills, and a natural affinity for technologies and sustainable solutions. This makes it all the more important to equip young talents so that they can take on their tasks with confidence and actively drive change.”

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News