The powertrain industry operates at the very edge of possibility. Working to the tight tolerances that this sector demands is not merely a goal, it is an absolute necessity for efficiency, performance, and longevity. However, many manufacturers are finding their ambitions hampered by an increasingly common challenge: a struggle to maintain and operate outdated machinery.

Most companies we speak to are facing a dual crisis. On one hand, they are relying on production assets, often over thirty years old, which may be unguarded and are certainly inefficient by today’s standards. On the other hand, they are finding it impossible to find staff willing or capable of running these legacy machines, compounding the problem with struggles for spare parts and trained personnel. If this predicament sounds familiar, it is time to look toward a comprehensive, modern manufacturing solution.

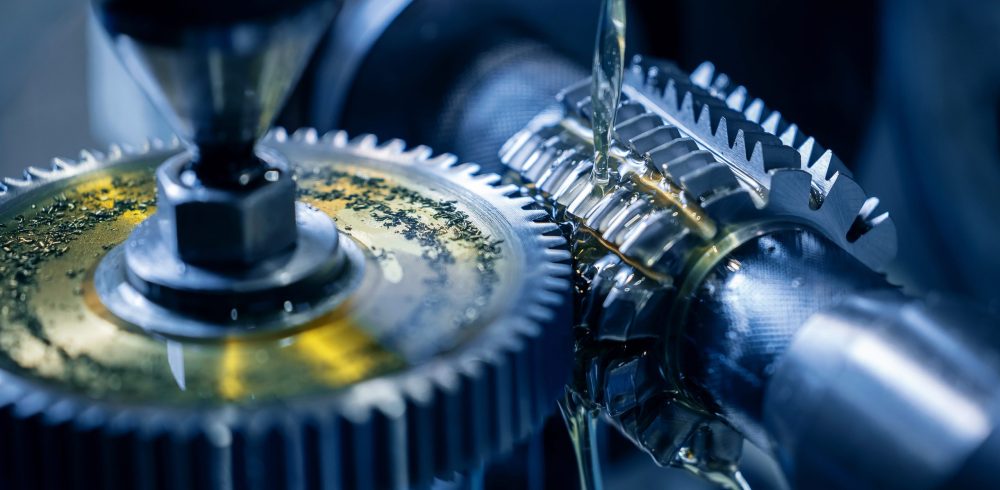

For nearly 100 years, delapena has specialised in making microns manageable. This century of expertise has allowed the company to develop and curate a portfolio of world-class machinery designed to address the most demanding requirements for grinding, hobbing, and honing tight tolerance parts. Whether the component is a high-precision shaft, a complex eccentric feature, or a critical gear, delapena offers the technology to ensure accuracy and consistency.

Our selection of grinding machines covers the full spectrum of precision component manufacturing. For rotationally symmetrical parts, we supply a range of Cylindrical and Universal Grinders ideal for shafts, alongside specialist CAM grinders perfectly suited for eccentric features and camshafts. Gear manufacturers can benefit from internal and external gear grinders, as well as internal and external spline grinders and dedicated gear hobbing machines, all engineered to meet the stringent standards of the modern powertrain. And, naturally, we continue to offer a comprehensive range of industry-leading honing machines, an area where the delapena name has become globally synonymous with surface finishing excellence.

This extensive capability is underpinned by a commitment to quality and partnership. The delapena catalogue boasts a selection of honing machines manufactured right here in the UK, alongside cutting-edge grinding technology from a selection of trusted partners. This strategic approach ensures that we are perfectly positioned to help solve a multitude of manufacturing issues, from bottlenecks caused by antiquated equipment to the need for specific, high-precision finishing processes.

The challenge of staffing and maintaining vintage machinery is a direct drain on capital, time, and ultimately, production quality. By investing in modern, high-precision machines, companies can simplify operations, improve safety, reduce reliance on hard-to-find spares, and offer an environment more appealing to the next generation of skilled technicians.

The path to overcoming these constraints lies in embracing modern, accurate, and reliable machinery. Get in touch with delapena now to explore our solutions. sales@delapena.co.uk Telephone 01242 546526

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News