Deep hole drilling is often a critical bottleneck in manufacturing, as chip jams or tool breakages can result in costly scrap and delay deliveries of high-value components like turbine parts or medical implants. As these specialised tasks increasingly move to universal machining centres, where operators may lack specific technical expertise, the limitations of classical drilling cycles with rigid parameters become a major risk.

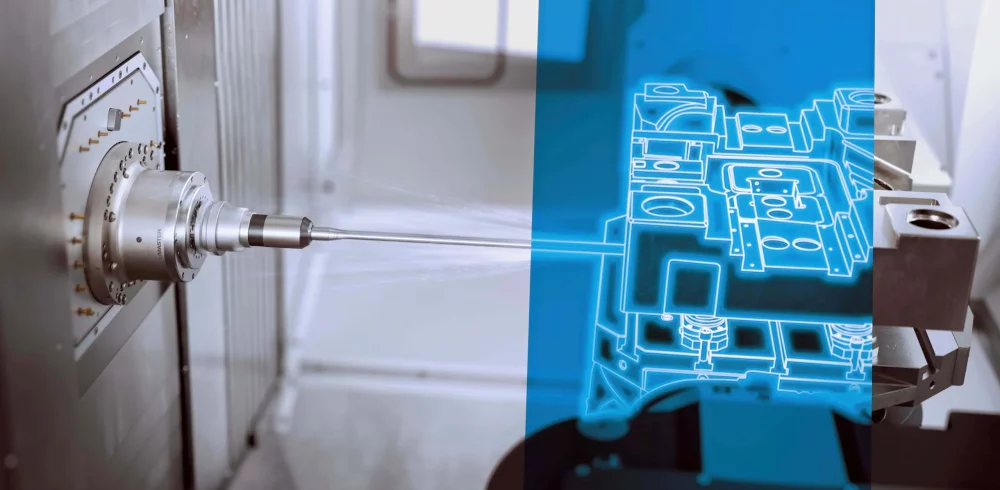

To alleviate the problem, a new adaptive drilling control (ADC) technology cycle has been introduced by DMG MORI to assist machinists when drilling deep holes on one of its machining centres. There are three modes for standard drilling, deep hole drilling and complex gun drilling applications. For standard tasks, the operator needs only basic drilling data, while the more advanced modes offer options for cross holes and adaptive feed adjustments.

Unveiled at the company’s in-house exhibition in Pfronten, Germany in early 2026, the system represents a major advance in process reliability, bore surface quality and user-friendliness. It transforms complex drilling operations that were once dependent on operator experience into a fully-controlled, actively-monitored machining process with quantifiable performance metrics.

By continuously capturing information on coolant pressure and flow rate as well as spindle load from sensors within its machines, and integrating the data into a closed-loop control system, DMG MORI has designed the new cycle to automatically optimise the parameters while adapting machining strategy in real time. Users achieve enhanced process stability, higher quality and a 30 percent increase in tool life, along with up to a similar saving in energy costs compared with employing cycles with rigid parameters.

Developed in collaboration with leading tooling and coolant partners in the DMG MORI Qualified Products (DMQP) network, including botek Präzisionsbohrtechnik, Gühring, Kennametal, Walter and FUCHS Lubricants, ADC delivers a complete solution for demanding sectors where accountability, documentation and process consistency are critical. It will initially be available on monoBLOCK, duoBLOCK, DMC H monoBLOCK, DMC 55 H TWIN and portal/gantry machining centres in the DMG MORI range and is compatible with both Siemens and Heidenhain controls.

As with the dozens of other technology cycles available, ADC integrates with DMG MORI’s CELOS X ecosystem, a unified front-end HMI sitting directly above the machine control that intelligently bundles information from the software, hardware and sensors. Consistent with Industry 4.0 practices, all process data generated during a drilling cycle is automatically recorded and made available for monitoring and analysis.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News