Jewel Fire’s packaging challenge

Jewel Fire Group, a distinguished supplier of fire protection equipment headquartered in Rotherham, encountered a substantial packaging challenge. Their buyer, Kelvin Staniforth, connected with our Smurfit Kappa team via website enquiry to address an urgent matter related to the packaging of their fire extinguishers. Despite maintaining a six-year partnership with a local supplier, escalating costs and an alarming 10% postal damage rate led to considerable frustration and prompted the need for a change. These damages, primarily stemming from inefficient cardboard packaging and a labour-intensive assembly process, resulted in a significant loss, raising concerns within the company.

Fired up

Within two days, Smurfit Kappa paid a visit to Jewel Fire, and after discussions, it became evident that the issue extended beyond just pricing – the current boxes were not fit for purpose to survive within the postal system.

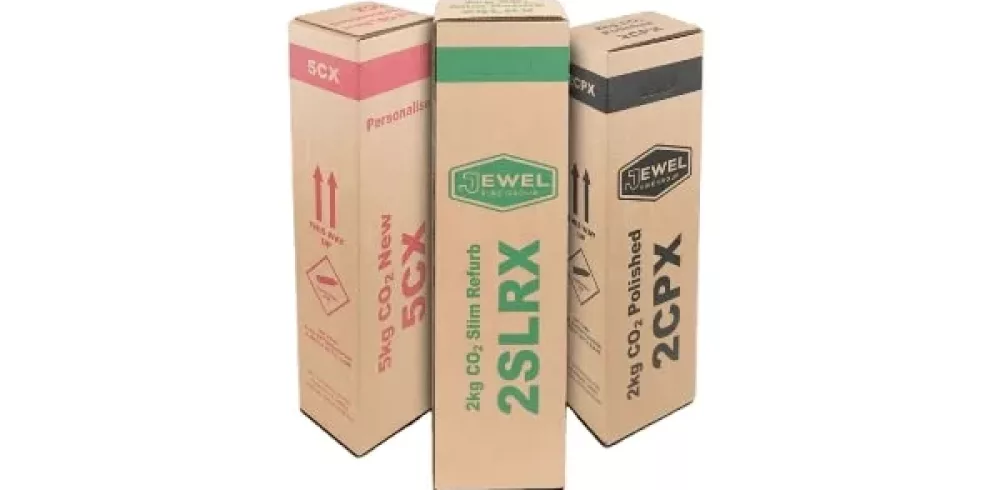

This is where our Chesterfield team’s design department came into play, leveraging their expertise in hazardous cardboard packaging and UN-certified packaging for dangerous goods. The team embarked on a creative journey to redesign the fire extinguisher packaging, opting for ISTA-certified boxes. After subjecting these boxes to rigorous testing against Jewel Fire’s current dangerous goods packaging, they devised a solution that incorporated an air buffer at the top and bottom of the packages. Additionally, by transitioning from a two-piece to a single-piece solution made from EB flute material, they not only enhanced the product’s appearance but also reduced labour and assembly costs too.

Sealing trust: from first impression to long-term partnership

Upon witnessing the superiority in design, print quality, and the swift responsiveness of Smurfit Kappa, Jewel Fire wasted no time and initiated orders for all of their key product lines. But the innovation didn’t end there. Acknowledging Jewel Fire’s spatial limitations, Smurfit Kappa Chesterfield took the initiative to maintain stock on their behalf, guaranteeing weekly deliveries. This approach not only optimised their inventory management but also upheld product quality and minimised the risk of obsolescence.

Packaging payoff

The outcomes were nothing short of impressive. Thanks to the redesigned fire extinguisher packaging and the introduction of durable dangerous goods cardboard boxes, Jewel Fire experienced a significant decrease in damages, resulting in substantial annual savings. Additionally, the transition to Smurfit Kappa’s one-piece cardboard transit packaging design further elevated their cost savings. This packaging transformation not only addressed their specific requirements but also enriched Jewel Fire’s customer service capabilities due to less damages and a superior experience overall.

Pathway to packaging perfection

At Smurfit Kappa, we offer a seamless blend of knowledge, experience, leadership, and a friendly advisory approach. As leaders in dangerous goods packaging and cardboard shipping boxes, we’re ready to address your most pressing packaging challenges. Our work with Jewel Fire underscores our commitment to innovation, and bottom-line benefits to our customers while ensuring product safety. If you’re searching for reliable and ingenious packaging solutions, get in touch today!

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News