Polar Technology, an Oxfordshire-based engineering and manufacturing business specialising in both metallic and composite technology, have recently installed a new filament winding machine as part of a designated, world-class manufacturing cell. This new investment is designed to increase and improve their volume production filament winding capabilities as they continue to support a varied, high-end customer base.

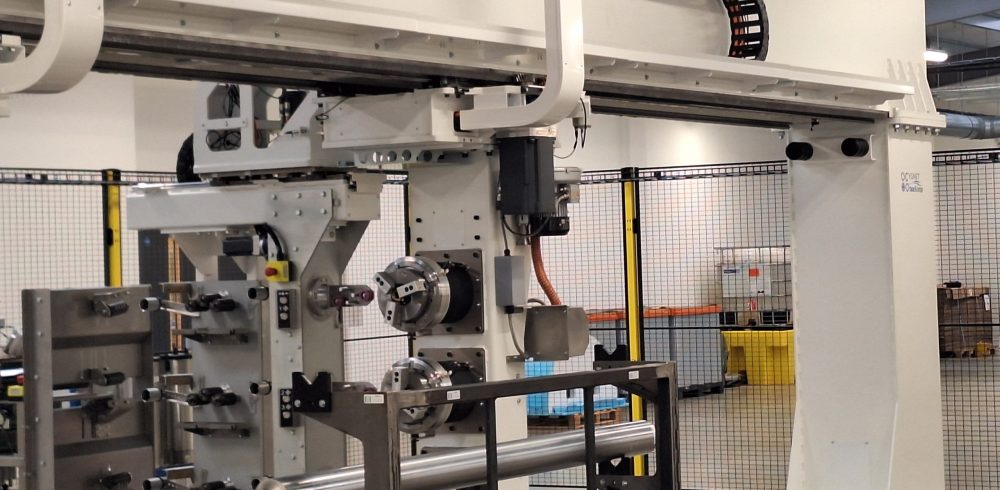

The dual mode, 3 spindle, 9 tow machine allows winding of components of varying sizes at high speeds, from small magnet rotor sleeves for advanced electric motors to 5m long hydrogen storage tanks.

This machine is just one element of a larger, dedicated cell, which will also include other advanced machinery, facilitating a comprehensive, streamlined and strictly quality-controlled process for higher volume production. This will ensure that Polar Technology are maximising reliability, repeatability and productivity in the products they provide their customers.

As a leading provider of filament wound products, the new facilities will serve to complement the existing winding capabilities at Polar’s 180,000 sq ft site, with their current product portfolio including, but by no means limited to, high-volume production of transmission shafts, pressure vessels and magnetic rotor retention sleeves.

The new facility will be used to support existing customers, fulfilling current contracts with capacity and capability to support further planned expansion and growth.

Edward Keating, Technical Project Manager at Polar Technology, who has overseen the implementation of the machine, said, “This investment in new equipment is a reflection of Polar’s unwavering commitment to support its customers in the drive to achieve Net Zero by 2030, and to explore new opportunities in growing markets. The new filament winding machine will support higher-volume manufacturing going forwards and increase our overall winding capabilities. It’s a project we’re all very excited about.”

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News