Offshore Electronics has invested more than £400,000 into its manufacturing headquarters in St Peter Port, Guernsey. Both production machinery and in-house communications have been upgraded to support the record levels of growth experienced by the business over the past year.

Offshore’s turnover hit £10 million for 2022/2023, with both new and existing customers signing multi-year agreements. As is now standard for the Guernsey-based CEM, the proceeds of this success are being redirected back into the business to support its long-term growth and move into new markets.

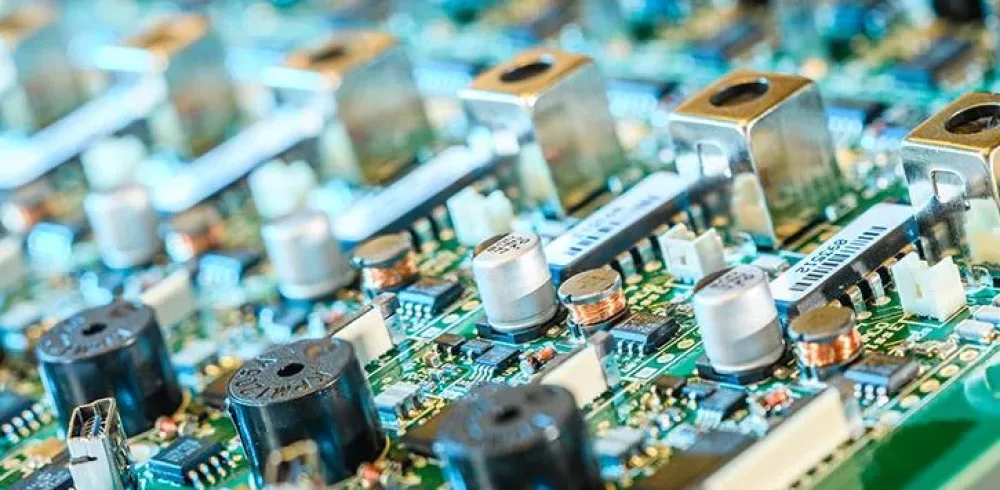

The investment will expand Offshore’s PCB production capabilities, increase productivity and connect employees working across its 20,000 sq. ft facility. Among the most important additions is a new axial component inserter from Southern Machinery, which will allow the business to position more than 20,000 axial parts per hour. This is a key upgrade as many customers have designs that rely heavily on this type of component. Offshore’s willingness to invest in this area guarantees a future for legacy products that would be cost-prohibitive to redesign for use with newer components.

New Inspex HD digital inspection cameras have been added to Offshore’s QA and surface mount departments. These cameras are important for quality control but also assist employees as components become smaller and more difficult to examine. Some parts now measure as little as 0.5mm x 0.2mm, making it impossible for the human eye to inspect adequately without magnification.

Offshore Electronics has also invested in the new Novastar Gold Wave soldering system, which will allow staff to rework or repair boards more efficiently. In addition to the Novastar is a new Heller surface mount oven and DEK screen printer, both replacing older models. Offshore has also installed CAT6 cabling, a new server, phone system and high-speed network connectivity for secure contact with clients across the world.

This latest outlay extends a pattern of investment, with the company having already purchased several other machines over the last 12 months. This includes a cutting-edge Yamaha Z:LEX YSM20R modular pick and place machine. The business has also made a significant commitment to sustainable PCB production, having recently signed off a major solar PV installation, due to be installed on the factory’s roof in 2024. This will provide roughly 11% of the company’s annual energy.

Paul van der Tang, Purchasing Director said: “Sustained investment in both people and technology is critical for maintaining a high standard of PCB production. This is a strategy we have adopted since starting in 1990 and it has continued to pay dividends, keeping us competitive in a crowded market. The latest round of capital is about cementing our position as a leading provider of electronics manufacturing services – both in Europe and beyond. It’s a signal of intent as we develop relationships with both long-standing customers and those new to our business.”

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News