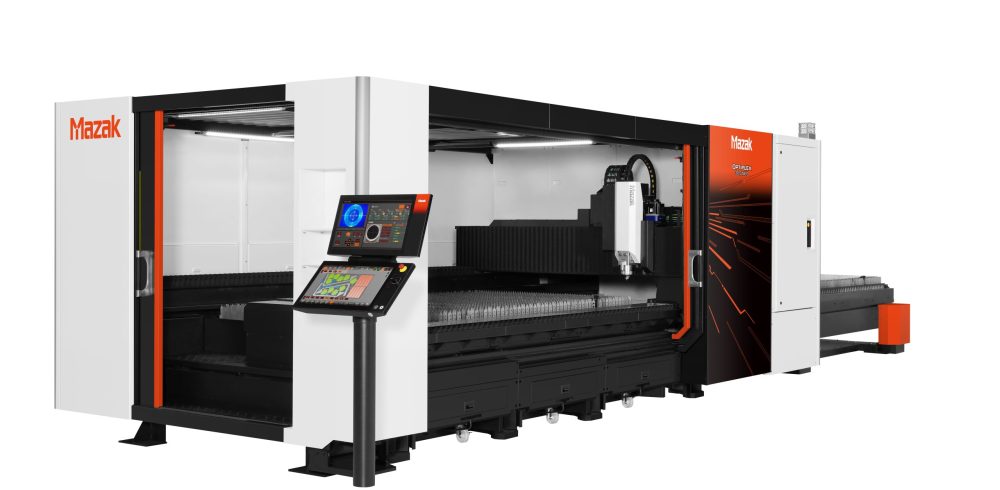

Yamazaki Mazak is excited to announce the European debut of the OPTIPLEX 3015 Ez, its latest affordable laser processing machine, at EuroBLECH 2024. This cutting-edge technology offers high-quality laser processing capabilities at a cost-effective price point, making advanced technology more accessible to a wider range of businesses.

Mazak comes to the exhibition intent on demonstrating its ability to support customers with end-to-end automation, high-power, high-accuracy cutting of thick material and how the synergy between the organisation’s laser processing and machine tool portfolio can help customers become more productive and more profitable.

With the launch of the OPTIPLEX 3015 Ez, which offers customers a user-friendly experience, affordability and exceptional performance, Yamazaki Mazak continues to demonstrate its commitment to delivering innovative solutions that meet the evolving needs of the manufacturing industry.

Designed for a large variety of materials and thicknesses, the machine offers precision cutting, high mechanical rigidity and unwavering reliability. Intelligent Functions empower users with efficient supportive and preventive measures, minimizing setup time to achieve optimized productivity.

The 6kW machine on display at EuroBLECH will be exhibited as part of a fully integrated manufacturing cell, which takes the workpiece from raw material through to the finished parts.

In addition to the OPTIPLEX Ez, which is equipped with a three-pallet changer to optimize cycle time, the cell comprises a Mazak CST 3015 storage automation system featuring eight shelves: six for the loading of raw materials and two for unloading of remnant sheets. It also features a Mazak SMART MANUFACTURING CELL robot sorting system to separate the finished parts and place them on a pallet ready for the next process.

Each component in the cell is coordinated centrally by the new Smooth Line Controller software. Built into the CNC, the Smooth Line Controller app allows the entire process to be integrated, from order receipt and program arrival from the CAD/CAM office through to material arrival, cutting, sorting and finished part shipment. The system, which can be used to schedule production, is also able to send critical production data back into the ERP system.

Also on display at EuroBLECH with be Mazak’s latest fiber laser processing machine, the OPTIPLEX 3015 NEO. The 20kW variant exhibited at the show belongs to Mazak’s NEO series of high-performance machines that excel in delivering exceptional productivity and precision, while also providing best-in-class environmental performance.

The machine’s working area allows the processing of workpieces up to 1525mm x 3050mm through a new 20kW fiber laser resonator. Thanks to a high-power laser and a new GRAND CUT technology the machine provides high-accuracy and stable cutting for thick material.

One of the machine’s standout features is Mazak’s Beam Shaping Technology which, complemented by the Beam Diameter Control in the machine’s Multi-Control Torch 3 cutting head, delivers substantial productivity enhancements and superior cutting quality for sheet metal processing.

By adjusting the beam shape, operators are now able to cut material up to 50mm with four times more stability compared to conventional cutting. Adjusting the beam shape can also improve the bevel angle by more than 80% versus conventional machines, significantly increasing the accuracy of the cut.

Visitors to the Mazak stand can witness the innovative Beam Shaping and GRAND CUT technologies in action and evaluate the quality of Mazak through the demonstration pieces being cut.

The synergy between Mazak’s laser and machine tool portfolio can reduce cycle time and tooling costs for end users. This will be demonstrated by the OPTIPLEX 3015 NEO 20kw and Mazak’s new Friction Stir Welding (FSW) machine, through laser processing an aluminum sheet on-stand and passing the cut sample to the machine tool to be friction stir welded.

Purpose-built to overcome the key challenges faced by manufacturers adopting FSW technology to join materials, Mazak has created the heavy-duty and highly rigid FSW-460V with a sizeable 900mm x 460mm table that can accommodate loads up to 500kg. This provides a foundation for the FSW-460V spindle to reliably and consistently generate a maximum thrust force of 14kN with a spindle speed of up to 10,000rpm for high-speed welding.

Gaetano Lo Guzzo, Director Laser Business Europe at Yamazaki Mazak, said: “EuroBLECH is the pre-eminent laser processing show in Europe and we are excited to once again return with three innovative laser processing solutions that can help our customers to become more productive and more profitable.

“The OPTIPLEX Ez is the culmination of years of R&D to bring to market an affordable laser machine that is easy to use and maintain without compromising on the quality synonymous with Mazak. Displaying it as part of a turnkey cell that automates the entire process, from raw material to finished parts, shows its true potential for helping customers seamlessly integrate laser processing into their manufacturing operations.

“For more established laser users, the new Beam Shaping and GRAND CUT technologies built into the OPTIPLEX 3015 NEO will enable thicker material to be cut much more accurately, with a higher surface finish. In turn, this will reduce the amount of post-processing work needed, once again helping operators to increase their productivity and profitability.”

For more information, please visit: https://discover.mazakeu.com/euroblech2024/.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News