Whether degreasing, classic component cleaning or high-purity applications – the demands on cleaning solutions have increased in all areas of the manufacturing industry. Ecoclean is responding to these changed market requirements with an even broader and more modularized product range. The focus here is on higher cleaning quality, improved costs, and more energy-efficient processes.

Component cleaning is an essential manufacturing step in all industrial sectors to ensure requirement-compliant downstream processes and high, stable product quality. Regardless of the industry, new and modified products, increasingly compact and complex geometries, an ever-greater variety of materials, and workpiece dimensions ranging from one millimeter or less to several meters all contribute to the fact that the spectrum of required cleaning applications is more diverse today than ever before. The demands on the process and the cleanliness to be achieved vary depending on the production stage as well as on the product and industry. For example, in the final cleaning of high-tech components, including those for the semiconductor industry, medical, sensor and analysis technology, and precision optics, particulate contamination in the nanometer range and nanolayers of residual film contamination must be removed. In contrast, in general industry, for example, with its very different areas and components, the first task is often to clean off large quantities of chips and machining media. Frequently, factors such as high throughput requirements, heavy workpieces, a widely varying range of components and short

delivery times also play a role. In addition, cleaning must in any case be economical, energy-efficient, and resource-efficient.

Adapt cleaning solution to the task

To optimally adapt a cleaning solution to the task at hand, other product and company specific criteria must be considered in addition to the cleanliness specifications to be met. This requires a manufacturer whose product range offers corresponding flexibility in terms of the cleaning media to be used as well as the plant and process technologies. As a full-range supplier of future-oriented, flexible, and energy-efficient solutions for industrial component cleaning, Ecoclean and UCM, the Group’s division specializing in precision and ultra-fine cleaning, cover the entire spectrum of wet-chemical processes using water-based media, solvents and modified alcohols. This means that cleaning processes and systems, including the most suitable process and drying technologies for both batch and individual part cleaning, can be very efficiently tailored to product and company-specific requirements. Process design is carried out in the company’s own test centers, with cleanroom test centers with adapted plant and measuring technology available for tasks in medical technology and for high-purity applications.

Modular system makes special chamber systems available more quickly

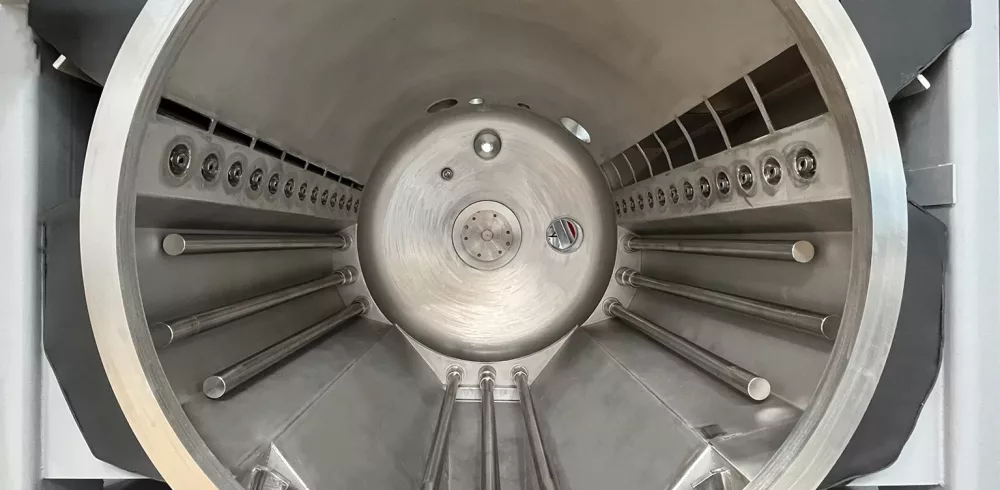

With a broad range of standardized chamber systems for cleaning with water-based media, solvents, and modified alcohols, as well as a wide variety of process technologies such as spray and high-pressure cleaning, ultrasonics, injection flood washing (IFW), vapor degreasing, Ultrasonic Plus, Pulsated Pressure Cleaning (PPC) and plasma cleaning, Ecoclean covers most cleaning tasks in general industry as well as the automotive and supplier sectors. However, applications that required individually designed special equipment, for example due to component dimensions, throughput requirements, cleanliness specifications or other company-specific factors, have increased significantly in recent years. To reduce the design effort required for this and shorten delivery times, the plant manufacturer has developed the innovative modular systems EcoCvela for water-based cleaning and EcoCstretch for cleaning with solvents or modified alcohol.

For the solvent systems, the modular concept includes four working chamber sizes with diameters from 750 to 1,200 mm and equipment with several flood tanks. For individual cleaning processes, the systems can be equipped with all process technologies available for solvent cleaning. With the EcoCvela, the diameters of the modular working chambers vary from 650 to 1,500 mm. In addition, the plants can be equipped with several working chambers and flood tanks. In these highly flexible plants, various process technologies and systems for efficient heat recovery also ensure short process times and energy-saving operation. For very high cleanliness requirements, both plant types can also be supplied with the corresponding high-purity equipment.

Modular solutions also for multi-bath ultrasonic cleaning

In the area of multi-bath ultrasonic cleaning systems, solutions consisting of standardized modules are also offered in the form of the UCMBaseLine, UCMSmartLine, UCMPerformanceLine and UCMHighLine model series. With the modules for the process steps cleaning, rinsing, PPC, drying, loading, and unloading, as well as a flexible transport system, cleaning systems for a wide range of applications can be configured and commissioned cost-effectively and easily. This is also supported by the fact that the electrical and control technology is already integrated. For high purity applications, the systems are designed with the appropriate equipment and for operation in or connection to a cleanroom.

With its further diversified portfolio, Ecoclean enables companies from all industrial sectors to meet changing cleaning requirements not only in an economical and stable manner, but also in a resource-saving and future-oriented way.

The modular EcoCstretch concept was developed for solvent cleaning applications that previously required special equipment with complex design and long production times. Among other things, it includes four working chamber sizes and several flood tanks.

Special plants for water-based cleaning are covered by the modular EcoCvela with working chamber diameters up to 1,500 mm as well as several flood tanks and, if required, several working chambers. For energy-efficient and fast cleaning processes, the plants have effective heat recovery and can be equipped with different process technologies.

With the multi-bath ultrasonic cleaning systems consisting of standardized modules, here a UCM PerformanceLine, cleaning solutions can be individually configured, for example for ultra-fine cleaning and high-purity applications.

www.ecoclean-group.net

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News