Digital Anoprinting refers to a process used to print aluminium. The process starts by using a special ‘open pore’ aluminium, which is permeable to the inks used to print it using a specialist printer. The anoprint process can achieve fine detail such as technical scales requiring precision accuracy (+/- 0.1mm), to full colour photographic quality images, logos and branding.

Open pore aluminium is 100% recyclable and offers a long life for finished products, as well as this it is produced in an environmentally friendly manner, using green electricity in its production. The inks used are solvent based and developed specifically for optimal digital anoprinting results.

Once the aluminium has been printed, the print is then ‘sealed’ in a post treatment water tank – like a very hot bath. This process seals the open pores creating an extremely durable print which is resistant to extreme wear, chemicals and solvents – even with heavy use. Unlike a direct digital surface print, anoprinting has a completely smooth finish due to the print being under the surface, adding to its superior durability.

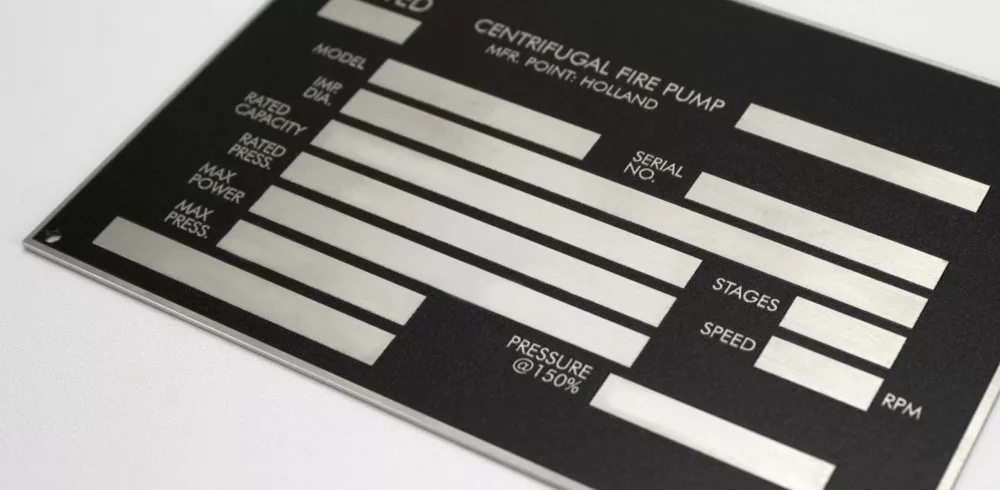

Typical applications include metal nameplates, plaques, badges, wayfinding both indoor and outdoor, signage and decorative panels. Combining this with precision laser cutting allows for the cutting of almost any shape, including multiple internal cut outs for the likes of electronic and industrial panels.

As well as being able to create incredibly striking full colour designs, anoprinting allows for serialisation, personalisation, barcodes and QR codes/Data Matrix. Each individual piece can be printed with unique data as well as featuring any other design elements required, such as branding.

If you would like to discuss a project for digital anoprinting, contact Keith today. keith@finecut.co.uk | 01903 751666

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News