Teleworking Has Never Been So Easy Gaining 200h per Year Free : All processes have losses. Seeing them in real time is the best way to reduce them in Industry 4.0 or when referring to people’s work.

Telework has changed our lives but the truth is that more than 40% of supervisors do not want teleworking due to a lack of confidence in the productivity of working teams. To solve this problem, edinn has extended its revolutionary method of the 4 losses of all industrial production processes to people. People work in the same way as machines in this respect and can be managed as OEE (Overall Equipment Effectiveness). Other systems only consider availability, while edinn considers the 4 types of losses in any working process.

In fact, people may have problems of availability due to downtime or external failures, of speed because results are delayed, of quality because results are not optimal, and of consumption because they register an excess.

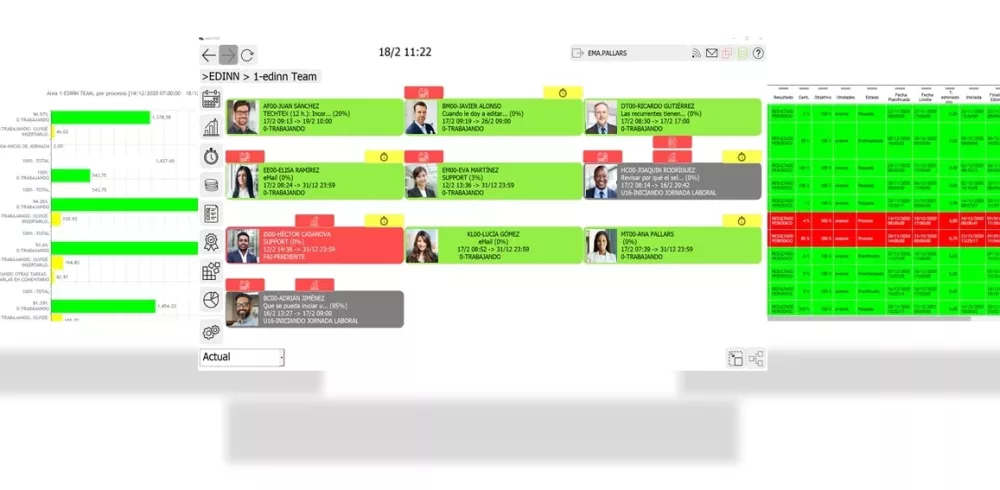

That is why edinn created the Work Management Module which is a tool that increases productivity and efficiency of machinery and people, working from an office or remotely. It also increases visibility, sensation of a team, traceability, and control. Edinn measures performance and helps and motivates us to do better. What is also very interesting is that it can be a base to progressively incorporate more tools and analysis to continually improve our performance.

Which tool do you need to have 200h per year free? Edinn is the perfect base technological platform for any Industry 4.0 & Work Management project. It includes the necessary “core” elements, and it allows, using the favorite development environment, to solve any additional need through its standard API.

The core elements of the edinn platform are Production Control (Manufacturing Execution System, MES), Work Management, Internet of Things (IoT) and Optimization via Operational Intelligence (OI), Big Data and Machine Learning.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News