Anyone aiming to machine complex components economically and with process reliability today needs ideas, experience, teamwork – and, above all, a digital manufacturing process. That’s exactly what’s being developed at Mapal in Aalen. In a dedicated division – the Technology Expert Team – complex manufacturing processes are conceived, tested, and optimised for customers across a wide range of industries. Increasingly, this is done digitally – using Vericut, the simulation and optimisation software from CGTech. It saves time, prevents collisions – and provides clarity for everyone involved, even before the first chip is cut.

A Global Leader in Precision Tools

Mapal is a globally leading supplier of precision tools for machining. Founded in 1950 by Dr Georg Kress, the company has evolved from a small business making taps and woodworking machines into a global leader in precision tools for metalworking. Today, the company employs more than 5,000 people and operates in over 25 countries with its own facilities.

Now in its third generation of family ownership, led by Dr Jochen Kress, Mapal stands for continuity, innovation, and close partnerships with its customers. The company is recognised worldwide as a technology partner that develops tailored tooling and process solutions to enable efficient and sustainable manufacturing.

Specialist in Cubic Components

Mapal’s product range includes a wide array of machining tools such as reamers, drills, milling cutters, clamping systems, and compensation tools. A particular strength lies in machining cubic components, which are in demand in industries such as automotive, mechanical and plant engineering, and aerospace.

Customers often come with just a drawing, a blank – or simply a challenge – and Mapal delivers a complete manufacturing concept offering the most cost-effective solution. “We see ourselves as a technology partner,” says Markus Kersten, Head of Engineering & Process in Mapal’s Technology Expert Team. “And it all starts with engineering.”

The Technology Expert Team (TET) is the spearhead of this approach. Around 500 projects per year are handled here, with machining strategies, fixtures, and largely customised tools developed – 90% of them bespoke.

Digital Process Expertise

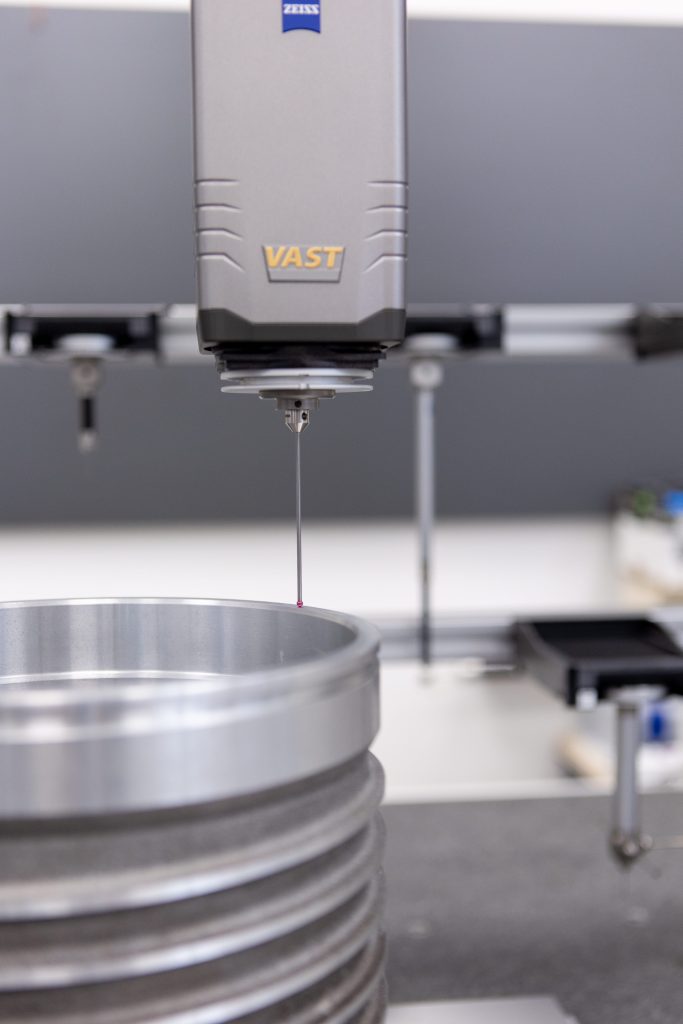

At Mapal, manufacturing is no longer just about chips and cutting data – it’s digital. In recent years, the company has consistently evolved: from traditional tool design to digitally supported process development. The integration of software solutions, data management systems, and virtual testing methods is now a core part of daily engineering.

A key tool on this journey is Vericut by CGTech – a simulation and optimisation software that helps Mapal test NC programmes realistically, run virtual machine simulations, and validate processes before any real cutting begins.

From Idea to Finished Process

At Mapal, the TET is far more than just a technical department – it’s the heart of complex customer solutions. It brings together all the necessary threads to analyse intricate components, develop holistic manufacturing processes, and implement them in practice. Whether it’s a greenfield turnkey project, optimising a current line, or launching full production at the customer’s site.

Some 50 specialists, organised by component type, develop several hundred bespoke solutions each year. Everything is tailored precisely to the demands of each industry and application. The outcome is machining strategies, clamping concepts, and NC programmes that are not only technologically advanced but also economically viable. Collaboration with customers begins early – often before the first part is made. The goal is always the same: the best possible machining strategy – fast, precise, and trouble-free.

Virtual Commissioning Saves Real Time

In the past, processes were programmed, clamped, and commissioned – and in the worst case, started all over again. Today, things are different. “With Vericut, we have the digital twin of the process on the desk, giving us tremendous confidence before any chips are cut,” says Lars Ziegler, CAD/CAM Team Leader in the TET. The software checks for collisions, analyses interferences, highlights optimisation potential, and provides precise previews of cycle times and tool paths. “We can visualise operations that are difficult or impossible to see on the actual machine – it’s a gamechanger.”

Rather than losing time at the customer’s machine, Mapal now commissions processes virtually – including all tools, fixtures, and machine parameters. “This greatly reduces the setup time on-site and helps prevent nasty surprises,” adds Lars Ziegler. Manuel Boaretti, NC Programmer in the TET, agrees: “Errors are detected early, and the necessary adjustments can be made quickly in the virtual machine. It’s a real quantum leap.”

A Partnership of Equals

The cooperation between Mapal and CGTech shows what true partnership on equal footing looks like. Both sides contribute deep expertise and share a common goal: to bring complex processes to the machine reliably and efficiently.

For Mapal, flexibility is key. The company works with a variety of CAM systems and machine controls. “Vericut is the unifying factor, as it is completely system-independent. Whether data comes from different CAM systems or is destined for different machines – Vericut produces a consistent, verifiable, and visual result,” says Markus Rettenberger, Sales Manager at CGTech. In some cases, Mapal even programmes directly on the machine control – and these NC programmes can also be reliably simulated.

For Markus Rettenberger, the collaboration with Mapal goes far beyond a typical project-based relationship: “This isn’t about customer and supplier – we work as partners, with a shared goal: to deliver outstanding results for Mapal’s customers.”

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News