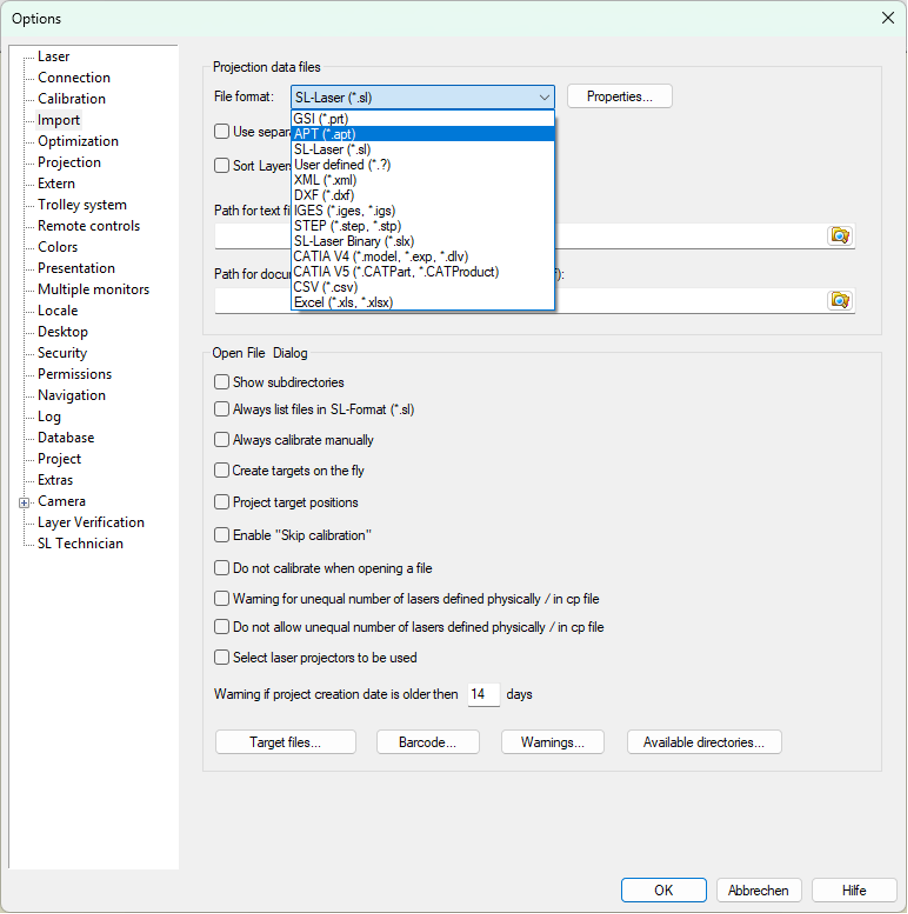

SL3D is a software solution for 3D laser projection of various shapes onto different tools. It supports importing files from common CAD systems such as CATIA, FiberSIM, ProE, and AutoCAD. SL3D can import IGES, STEP, APT, PLY, XML, DXF, SL, CSV, and Excel files.

Our SL3D software and projectors can manage up to eight independent tools or molds, projecting onto all of them simultaneously. The operator simply selects the mold and the desired ply.

SL3D is primarily used in the composite lay-up process and for projecting fixtures, holders, click bonds, or even wiring during assembly. The same software is also frequently used for part projection before welding. A wide range of features enhance the efficiency and quality of 3D projection, and additional license modules are available for special applications.

A key feature is the automatic calibration system, which ensures high accuracy in the lay-up process and significantly reduces calibration time. The electronic ply book function provides comprehensive quality control documentation, allowing seamless integration into existing production workflows.

Key features include:

- Automatic projector selection : In multi-head systems, the software automatically selects the optimal projector for projecting a line or segment, based on the projector’s position relative to the mold.

- Point reduction/optimization : Reduces the number of points in a ply file to optimize projection speed and minimize flicker, while maintaining necessary accuracy.

- Password-protected operator levels : Scalable security allows access to software features only as assigned by the administrator. For example, standard users cannot modify data.

- Optional biometric authentication : Operator access levels and identity can be verified via fingerprint scanning using a special keyboard.

- Optional barcode scanner : For quick ply information retrieval.

Extended user rights offer advantages such as :

- Granting operators additional permissions for certain functions.

- Options like manual calibration or menu access.

- Allowing operators to confirm specific steps without requiring administrator approval each time.

Process Security for Operators

Additional online guides for production, provided as text or graphical information, are displayed on-screen with the corresponding layer. For example, a drawing or photo can show how to perform a specific step. This information appears either by programmer command or automatically when a layer is selected.

Trolley system support

- SL3D supports laser rail (trolley) systems, allowing two trolleys to work on the same tool, and then independently on different tools after finishing.

- Work positions can be predefined.

- To simplify operations, SL3D allows the use of multiple monitors for different tools, all managed by a single SL3D software instance. Each workstation has its own screen displaying relevant information.

- Screens can be wall-mounted or freestanding, providing operators with detailed instructions, including PDFs or JPEGs for visual guidance.

Vacuum Bagging Process Feature

- SL3D includes a vacuum bagging countdown protocol for external control.

- While the countdown is running, SL3D displays the current vacuum status as a percentage.

- The countdown does not start (display remains gray) until the minimum vacuum value is reached.

- Once the minimum value is achieved, the countdown begins, and the display turns green

Visit sl-laser.com to find out more

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News