Xometry launched in 2014 and has grown rapidly with an easy to use instant quoting platform. In 2018, acquired MakeTime, another leader in the manufacturing-on-demand space to create the single largest manufacturing partner network in the industry. In 2019, acquired Shift, Europe’s largest CNC manufacturing network. Xometry’s partner network now spans the globe to supporting the needs of customers and drives the business of local machine shops and manufacturing facilities. Partners do not pay to sign up for this network. Xometry utilise a unique algorithm sending jobs to a list of carefully vetted facilities with matched capabilities. Xometry also have their own Project Engineering team ensuring the required component parts are correct and on time.

What is Xometry?

Xometry is the world’s largest on-demand manufacturing platform. It offers huge production capacities, instant online quotes and market sensitive pricing. European network of over 2000 manufacturing sites allows the maintainence of quick turnaround times while offering a wide range of capabilities

Who do Xometry work with?

Xometry works with a diverse client base, serving start-ups to Fortune 100 companies, like Bosch or BMW, all across Europe including the UK, Norway, and Switzerland. The company can manufacture anything from a single prototype to 100,000 parts and would be glad to work with you!

What do they offer to a UK & Ireland supply chain?

Xometry have wide capabilities including CNC Machining, Sheet Metal Fabrication, Direct Metal Laser Sintering (DMLS), Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), HP Multi Jet Fusion, PolyJet 3D, Die Casting, Binder Jetting, Urethane Casting, Finishing Services, and Injection Molding.

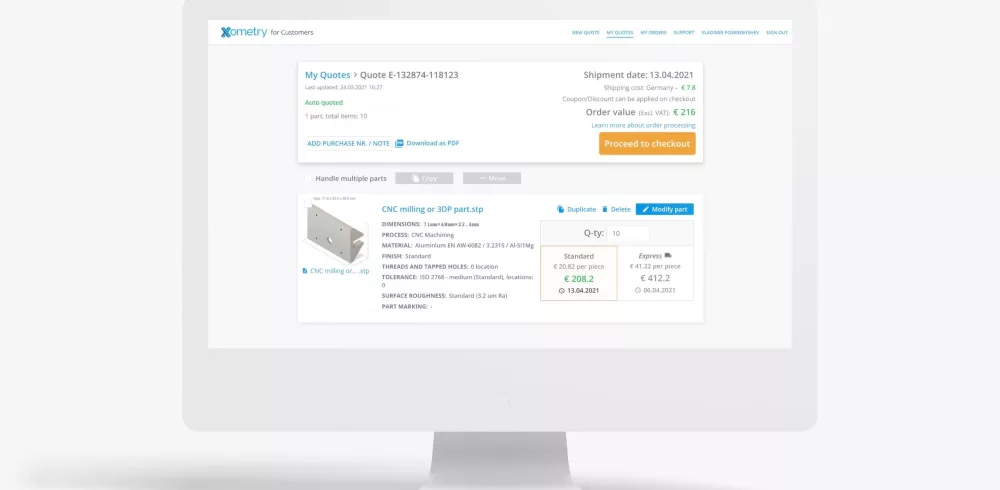

Xometry operates as a one-stop on-demand manufacturing solution for engineers and purchasers. It offers instant quotes for prototypes and serial parts, the ability to compare prices and lead times, and for companies to order the best option in a matter of seconds by just uploading a CAD file and choosing the required manufacturing specs. A 21st century supply chain solution.

The company offers these manufacturing processes:

- CNC machining: milling, turning, drilling

- 3D printing: SLS, HP MJF, SLA, FDM, Carbon DLS, DMLS (metal 3D printing)

- Sheet metal: laser, plasma and water jet cutting

- Injection moulding (manual quote in 48 hours)

Xometry shared with MEM that customers are able to choose from over 50 materials and get parts produced in up to 3 business days (3D printing) or 10 business days (CNC machining and sheet metal processing). This is available through the

Xometry Instant Quoting Engine which is completely free to use and user friendly.

As this is the first time MEM has featured Xometry, there is a unique discount available to our subscribers and readers of Manufacturing & Engineering magazine. This is a special promotion, where Xometry Europe is offering a 7% discount for the readers of Manufacturing & Engineering Magazine for any custom & serial manufacturing projects which is valid until April 10, 2021.

All our subscribers and readers of this feature article need to use the promo code MEM7 at the checkout with Xometry.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News