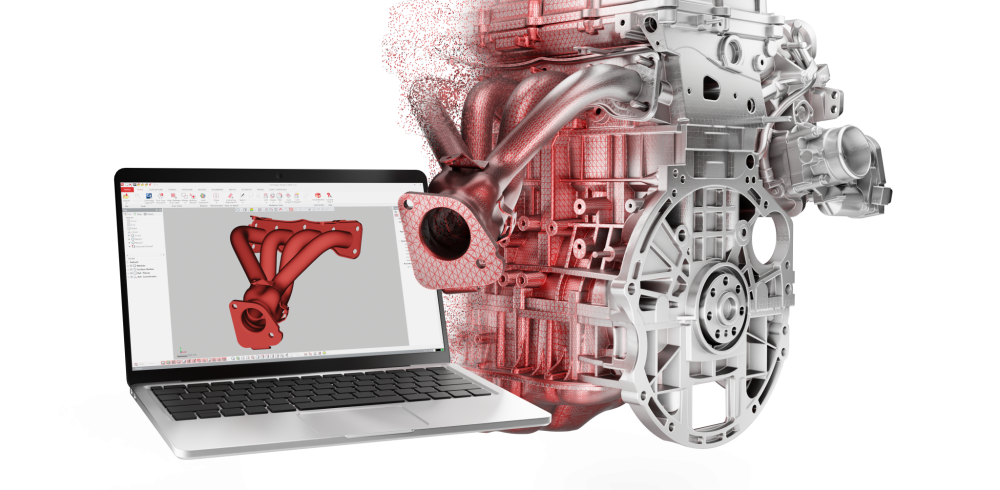

Hexagon’s Manufacturing Intelligence division is demonstrating the market-leading capabilities of its new reverse engineering workflows utilising Geomagic Design-X in combination with a wide range of 3D scanning technologies.

Successful scan-based reverse engineering of mechanical components makes it easier to modernise, improve, or replicate parts, minimising the costly errors that often occur with manual feature measurements and outdated designs. Despite its potential, the process is often considered too time-consuming, requiring specialist CAD and scanning expertise to translate incomplete scans into usable CAD models.

“In practice, reverse engineering even a single mechanical component is often a laborious process that might involve several people, unreliable results and manual repair,” said Johannes Mann, Senior Director Industry Solutions at Hexagon’s Manufacturing Intelligence division. “With Geomagic Design X and today’s accessible 3D scanning equipment, it’s now feasible to reverse engineer directly back into CAD with a productive workflow that engineers and manufacturing teams can easily adopt.”

- Capture and convert with confidence: Geomagic Design X provides the fastest path from 3D scan to fully editable parametric CAD models, combining direct scanner control with automated tools such as Region Segmentation, Modelling Wizards and Auto Sketch. Engineers can reliably create accurate, editable models from as-built parts or prototypes with full CAD history and parameterisation. Today’s products have complex shapes that are hard to recreate, here the software excels enabling the user to quickly process freeform shapes, surfaces to create usable NURBS and parametric CAD.

- Seamless CAD integration removes barriers to adoption: LiveTransfer™ technology enables manufacturers to move complete parametric models directly into leading CAD platforms including SOLIDWORKS®, Siemens NX®, Autodesk Inventor®, and PTC Creo®. This streamlined workflow reduces complexity, accelerates design cycles, and makes up-to-date models available for downstream use in assemblies, drawings, simulation, and manufacturing.

- Accuracy that reduces costs and risks: Automated Accuracy AnalyzerTM tools enable precise verification of deviations between constructed surfaces and 3D scan data at every stage of the workflow to ensure that the final CAD models are perfectly aligned with scan data. This reduces the risk of rework, tooling iterations, and fit issues. Its advanced mesh and point cloud processing make it possible to reverse engineer even complex organic shapes and customised designs that traditional methods miss.

Known for enabling high-precision industries to deliver quality at speed, Hexagon is enhancing support for scanners such as its award-winning SmartScan VR800 structured light scanner within Geomagic Design X, which is on show at EMO. This lets a single user scan large parts while zooming into critical details such as radii and drill holes in a single pass. The software’s advanced mesh handling and “Exact Surface” creation tool ensure that even intricate geometries are converted with high precision, giving manufacturers the flexibility to create parts that integrate seamlessly with existing systems or meet specific ergonomic needs.

“By using purpose built, scanner-agnostic software like Geomagic Design X, manufacturers can save time at every step of reverse engineering process,” concluded Mr Mann. “It flips the narrative from a challenging – but essential – labour into an accessible, routine capability that compliments CAD-native design and empowers teams to work with confidence.”

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News