Heatsense Cables Ltd, based in Rochdale, Greater Manchester, manufacture high performance cables and wires used in extreme environments. The company had seen significant growth, doubling within a couple of years, but Commercial Manager Aaron Hulse knew that they needed to change internal procedures; “The growth in business brought with it stresses and strains. We needed to put a solid system in place that would give us rules. We knew where we wanted to be, and we knew that we were never going to get there pushing spreadsheets and paper around – it’s ‘old school’.”

The main issues centred around planning and stock management. Stock was held in an Excel spreadsheet, with stock-takes manually performed every six months. As a result, stock outages were affecting on-time delivery performance, as products couldn’t be manufactured due to missing stock items.

The company started to evaluate MRP systems, initially investigating several systems but quickly narrowing down to two. The other vendor provided a demo of what the system could do, however this option was quickly discounted. Said Aaron; “It got quashed before we went very far, as it was clear that we would have to change our business to fit the system, not the other way around. It was also expensive, at around £50,000 for the software, plus implementation, training and annual maintenance.”

Heatsense attended a 123insight Evaluation Workshop in January 2020, which Aaron identified as a stark contrast to the other vendor; “The workshop was brilliant. There was no hard sell – it was all about the system and what it could give us. That really made our minds up.”

The decision was made to move forward with 123insight, however shortly afterwards the country was in lockdown due to the COVID-19 pandemic. Despite this, the company moved forward with the implementation, hiring a consultant with previous experience of implementing 123insight.

Staff attended training over a two-month period in the Summer of 2020, just after the first lockdown was lifted. Although the training is offered under no-obligation prior to registration, Heatsense were confident enough that 123insight would meet their needs and registered as a customer before attending the training.

Due to COVID, training was held online; which Aaron found a positive experience; “We were able to ask any questions we needed, and after this we were fully confident that the system would work for us – we asked the right questions and got the right answers.”

A series of implementation sessions were held online, with key staff being allocated tasks such as structuring bills of materials and routings, or re-shaping some of the existing Excel spreadsheets into the required format for importing into 123insight. Aaron said; “We aimed for a go-live over Christmas, took account of where we were and transferred it to 123insight so that we knew we could go live on the first day of January 2021.”

The company did go live in the New Year, and immediately saw benefits. “For the first time ever, the sales team could take a call and see live stock. Previously it might take up to an hour for someone to check stock and report back, and this might be 10-15 times a day. Invoicing and purchasing were quicker and now electronic, with documents being emailed as PDFs. Procurement also saw massive benefits, as we could immediately see what materials needed to be purchase, how much and what supplier to use, with most purchase orders being enacted and emailed to suppliers with a couple of clicks.”

Stock control itself improved, as minimum stock levels were set for all key materials, with overall inaccuracies drastically reduced. Stock locations allowed items to be found much quicker than before, so ex-stock items could be ordered, picked and despatched 50% quicker. As the stores department doesn’t have dedicated staff, a unified system delivered significant time savings; “All of our staff are multi-skilled, so we don’t have a dedicated person in stores or despatch. 123insight has given extra time to all the staff that perform these functions. I’d estimate this as at least a 25 % time-saving. It’s certainly freed up a lot of my time.”

Works orders saw an inclusion of much more information. Aaron explained; “Previously we would simply list a part number and rely on the experience of the staff as they had made the parts many times before, but this can lead to errors. Works orders now list both the materials and routings, plus we’re using document linking to include data sheets and other technical information.” While works orders included more content, it was estimated that paper usage overall dropped by 20%.

Lead times improved by 10% due to better stock availability and planning visibility. Like many in the industry, the company was hampered by supply chain issues, however the additional visibility that 123insight provided helped them to purchase more strategically to avoid stock outages. Aaron expects lead times to improve further as supply chain issues ease.

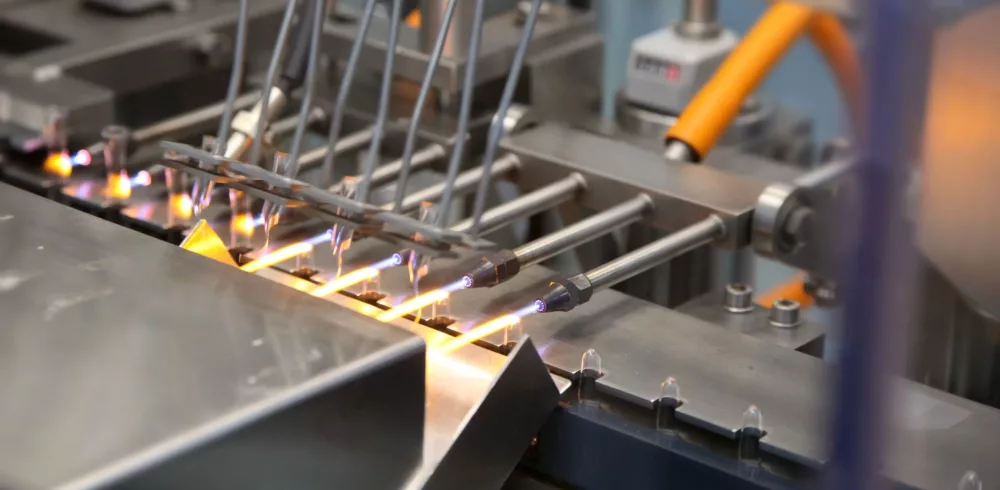

Aaron also noted that 123insight allowed them to apply consolidation across many areas, providing knock-on environmental benefits. Inbound deliveries from suppliers could be grouped, as could outbound deliveries to customers; “Depending on the product and urgency, we can now ask the customer if they would prefer us to send multiple orders together.” Consolidation also continued onto the shop floor; “We’re also now pairing jobs together. For example, if we have an extrusion job using red plastic, we might consider consolidating other jobs, reducing head waste and saving on material. This is especially important, as plastic waste is a hot topic right now.”

Heatsense already had ISO9001 and ISO14001 quality accreditations, but has plans to expand its business within the aerospace sector and therefore sought AS9100 accreditation. Said Aaron; “We are supplying testing and measurement cables for aircraft engine testing today, and are moving into onboard cables. 123insight is an important part of that because of traceability. Certainly during our AS9100 implementation and subsequent audit it was evident. Everything was visible, e.g. batch numbers, raw materials and who worked on which parts. Part of the audit was remote and all of the information was easily retrievable on-screen. In the old days we would have been looking through reams of files and scanning documents.”

Every industry has issues that are unique to them. When Heatsense produce a batch of products for stock, items within the batch might often be different lengths, requiring more work to book items in. Heatsense discussed this with their 123insight Customer Care Manager, who identified that a modification to the software would not only elegantly solve the problem for Heatsense, but by applying the same logic elsewhere would benefit other customers. Said Aaron; “It just shows that 123 Insight listen and are there to help. I can’t think of many suppliers that would consider a change to their system for a customer.” A third of 123insight’s monthly subscription is re-invested into development, with many new features based on customer feedback.

Heatsense also uses Access Dimensions accounts software, and later in 2021 decided to link it to 123insight using Accounts Gateway. This allows invoices to be created automatically within Access Dimensions, and 123insight users to be able to see data such as credit limits or if a customer is on stop.

With a system that is relied on company-wide, support is an important aspect, but Aaron could not be more pleased; “Support has been absolutely fantastic – I could not give them more credit. They are always at the end of the phone if I need them, and it’s always a positive experience. There’s no comparison with other suppliers, where I might be waiting 2-3 weeks for a simple answer.”

The overall flexibility of the system has also impressed Aaron; “The fluidity of 123insight is amazing – we can change the system to match what we are about as a business. I can’t fault the system, and I’ve already noted one of our suppliers using it.”

123 Insight focuses on customer education, ensuring that users can get the most out of the software. Aaron sent a colleague that had not attended the original training on a 123insight Customer Education Day; “I felt our Quality Manager needed additional knowledge, as he is working with auditors and needed a deeper understanding. He was amazed at some of the things that I hadn’t had time to show him.”

After already taking on larger premises, the company has significant growth plans for the future, moving more into supplying the aerospace sector now that they have AS9100 under their belt. Aaron finalised; “We could easily double in size with 123insight. We didn’t stop throughout the pandemic, employing more shop floor staff,buying more machinery and

taking on extra premises. One of the key tools it has given us is staff being able to quickly retrieve any information, reducing the need for more staff. 123insight was also essential to us gaining AS9100 approval, which the auditors acknowledged.”

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News