Multi-sourcing for a single product can be a time consuming drain on resources, not to mention a more costly way of purchasing. Often referred to as a “one stop shop” Fine Cut have a multitude of manufacturing processes under one roof, allowing many clients to ditch multi sourcing for their products. They have the capabilities to combine processes such as laser cutting with digital print, chemical etching and laser marking, making for a much smoother ordering process.

Fine Cut were approached by a leading manufacturer of motorsport test equipment who supply top end automotive clients including F1, Ferarri and other high end car manufacturers. The client contacted Fine Cut with a project for helping them make their product more visible and modern and to move it away from the old dull product identification they were using. For many years they had outsourced metal panels for screen printing, then further outsourced the panels for cutting, this all took time , in some cases leaving production with a small window to complete the build of the units which placed unnecessary pressure on an already busy production team. Utilising Fine Cuts diverse in house manufacturing processes meant drastically improving lead time and provided the production staff with more efficient production scheduling capabilities.

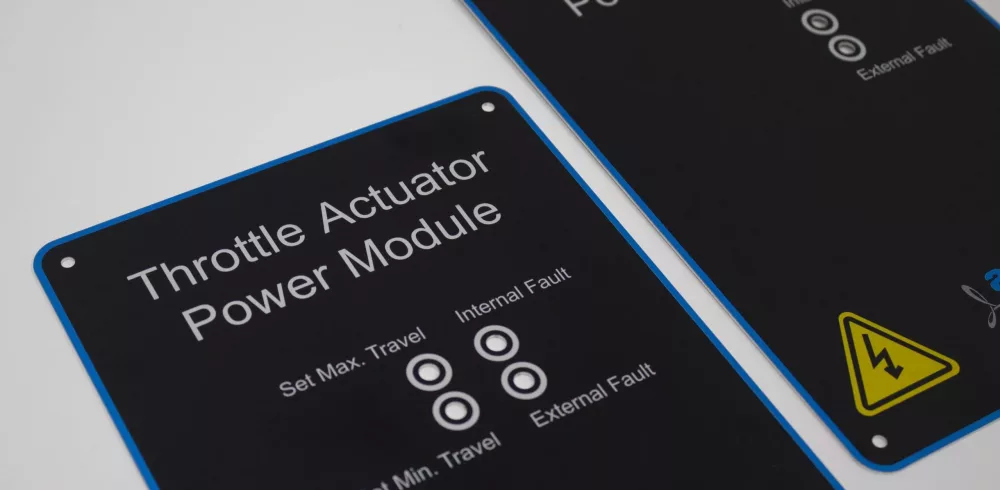

These metal panels are now digitally anoprinted with varying designs and sizes and are finished using precision laser cut profiles and apertures. Initially just manufacturing one variant of the panels, they now manufacture more than 10 different variants of the product. The updated more modern approach to manufacture has allowed the client much more scope on design whilst keeping their branding consistent across the range as well as being able to order high value products at low quantities with a much faster lead time.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News