A new technology that could significantly reduce the amount of energy and emissions associated with manufacturing plastics has been developed.

Scientists from ExxonMobil and the Georgia Institute of Technology claim the revolutionary material could cut the industryâs global annual carbon emissions by up to 45 million tons if it is brought to industrial scale.

Thatâs equivalent to energy-related carbon emissions of around five million homes in the US.

They add the technology could also reduce global energy costs used to make plastics by up to £2 billion a year.

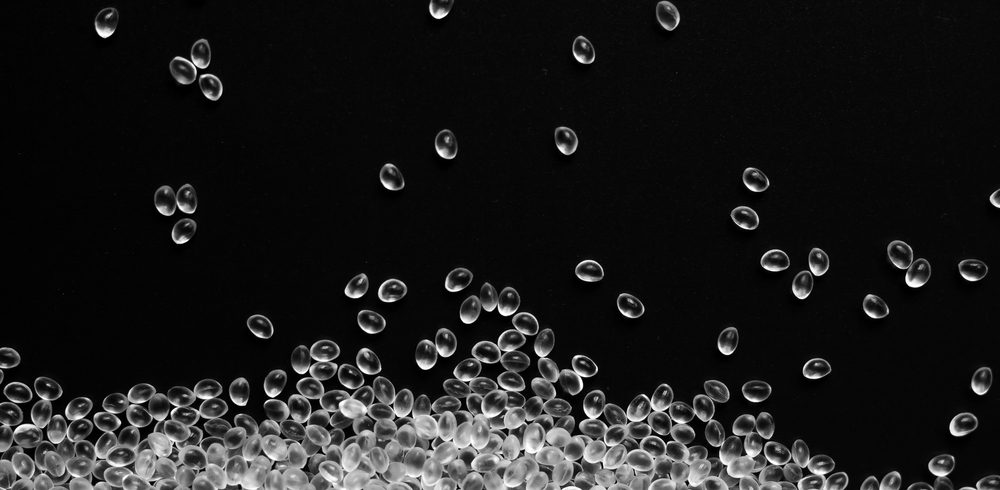

The scientists have developed a new plastic manufacturing process that use a molecular-level filter to separate the chemical para-xylene from other complex hydrocarbon mixtures.

Mike Kerby, Corporate Strategic Research Manager at ExxonMobil said: In effect, weâd be using a filter with microscopic holes to do what an enormous amount of heat and energy currently do in a chemical process similar to that found in oil refining.

Globally, the amount of energy used in conventional separation processes is equal to around 20 average-sized power plants, according to the energy company.

It claims the new method is around 50 times more energy efficient than the current separation technology.

Benjamin McCool, an advanced research associate at ExxonMobil and co-author of the research added: The implications could be enormous in terms of the amount of energy that could be saved and the emissions reduced in chemical and product manufacturing. Our next steps are to further the fundamental understanding in the lab to help develop a plan for pilot plant-scale demonstration and if successful, proceed to larger scale.