A Midlands-based manufacturer that can trace its roots back more than 200 years is using Industry 4.0 machine monitoring software from FourJaw to drive efficiency. Cast-nylon and plastic components manufacturer Westley Plastics has improved cycle times and achieved more consistent and efficient 24/7 production after adopting smart technology, which has given the company greater visibility of its manufacturing process.

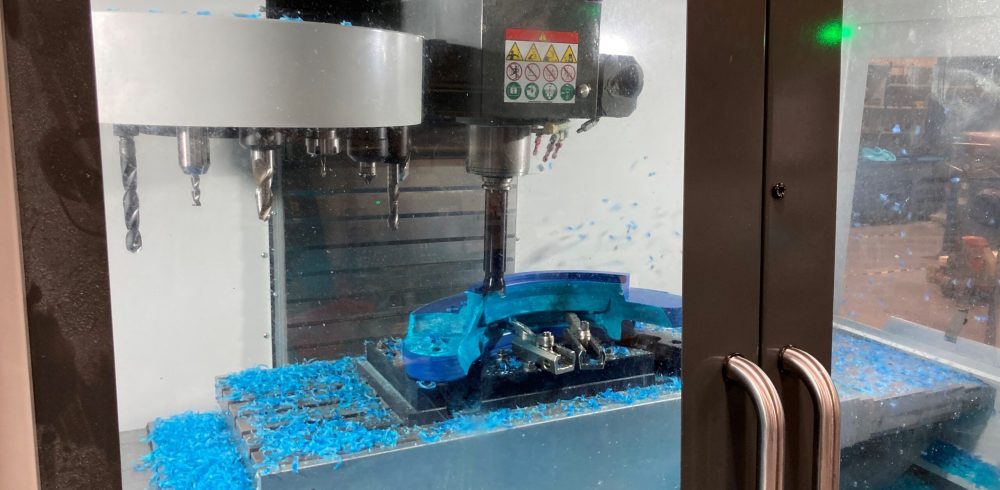

Westley Plastics is a family-run business that specialises in taking engineering plastic products from concept and design to final manufacture, utilising its on-site design, casting and CNC machining facilities. It works across several heavy industrial sectors including construction, defence, automotive, rail and steel.

The company operates 24 hours a day, but it wasn’t evident whether machine utilisation and productivity were consistent throughout any 24-hour period. It was agreed that greater visibility of the shop floor through machine monitoring would enable them to identify capacity and cycle times and help to focus the workforce on the processes that required and benefited most from their skills.

FourJaw’s manufacturing analytics platform, which works on machines of all types and ages, enabled the business to identify machine downtimes and understand the reasons behind the stoppages. Machine monitoring has also identified and improved cycle times. The team had previously discussed running two machines at the same time but didn’t think it could be done. However, the data from FourJaw revealed which machines could be run together – improving efficiency, productivity and job profitability.

Tom Westley, Operations Director said: “The information that the FourJaw platform provides has resulted in some very positive changes for the business, including the introduction of new production processes, improvements to the factory layout, and improved cycle times by creating new jigs, reducing on-job operations of big jobs by 50%.

“We now have a clear and informed picture of the factory floor including accurate cycle times and utilisation by shift. The factory is now more efficient and productive with its resources which is evidenced by the increased utilisation of machines running 24 hours during the week, which has improved so much that fewer shifts need to run over the weekend, saving the business money on staffing, energy and other operating costs.”

Westley Plastics’ smart factory strategy will include installing FourJaw machine monitoring to every machine that it adds to its manufacturing operations as it grows.

Oliver Pogmore, Head of Business Development at FourJaw, said: “Our MachineLink IIoT device can be easily and quickly self-installed on any manufacturing machine, regardless of brand, type or age, which makes it perfect for small and medium-sized businesses who’d prefer a low-cost, no-fuss ‘plug-and-play’ solution. By monitoring and analysing machine data, FourJaw enables manufacturers to make machines run productively and profitably. This is certainly the case for Westley Plastics.

“It’s always been important to get the most from your assets, but we are seeing a big uplift in manufacturers turning to smart technologies to ensure their machines are as productive and efficient as possible. Enabling them to offset some of the economic and inflationary pressures faced”

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News