A 3D liquid metal printing machine has been created by a father and son team that is being deemed so novel it could represent a quantum leap in the ability to print three-dimensional objects in metal. While other metal printers exist they often use a process of laying down powered metal and melting this with an electron or laser beam which the new development proves is unnecessary and inefficient.

The printer known as the Vader machine (after its creators) already has manufactures interest with an automotive parts marker stating they will be purchasing at least fifty for their company. A printer with multiple nozzles could cost excess of $1million. The Vaders worked on their invention in their home basement in Amherst when it was decided they would reach out to the UB for help in terms of grants, personnel and intellectual assistance to transform their idea into reality. They now have three faculty advisors and are part of the start-up NY tax free entrepreneurial programme, winning grants from UBâs centre for industrial effectiveness (UB TCIE). In addition, access to university students for internships has aided the development and in turn the company to expand. Vader systems has already hired three mechanical engineering graduates and this is expected to grow.

Inspiration for the Vader machine spawned when Zack Vaderâs plans to hire a company to 3D print parts for a microturbine generator were stymied as no company could issue the parts he needed. His breakthrough came thanks to his thought to expose molten metal in a confined chamber with an orifice to a pulsed magnetic field. The transient field induces a pressure with the metal that would eject a droplet, hence the key to making droplets of liquid metal that could come through a nozzle.

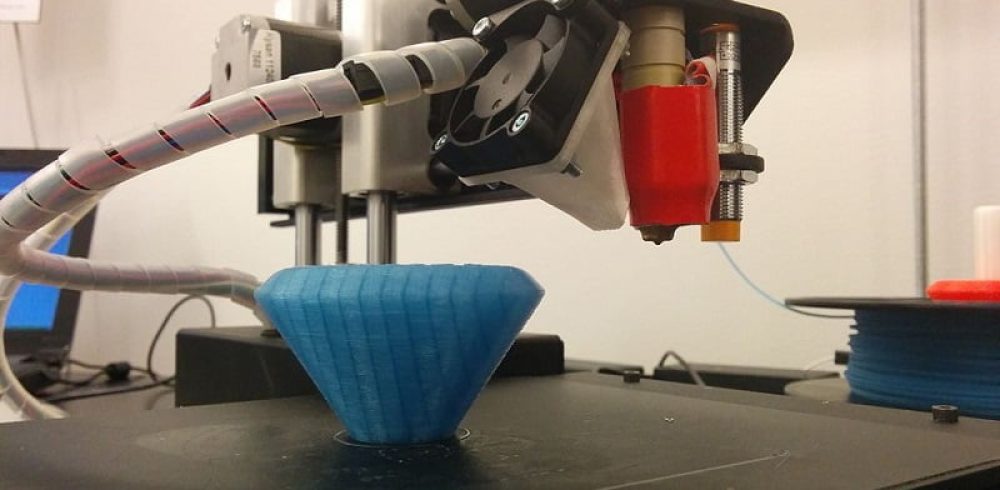

This process has been explained to mimic drop-on-demand ink jet printing based on the principles of magnetohydrodynamics. The printer is a way forward in transformative technology and interdisciplinary engineering which can be an application base used to boarded and expand developments in the foreseeable future.

The Vader Machine will be of great value to medical engineering fields especially in relation to custom hip and knee replacements. The game changing printer does not use the metal powder currently used in metal printing processes that can be toxin inside the body and remains difficult to clean up. Not only is the invention faster than previous applications it is greatly cheaper than using powdered metals.

As the machine develops and evolves, the Vaders plan to expand their operation into an assembly line manufacturing facility. The future of metal printing is thought to be dominated by the Vader machine.