Additive manufacturing or 3D printing has the potential to become the biggest single disruptive phenomenon to impact global industry since assembly lines were introduced to America in the early 20th Century. Any challenge to globalisation can be of huge disruption to the global transport industry yet the concept of 3D printing brings with it widespread opportunities for essential development in many fields worldwide.

The compelling logic surrounding 3D printing means products that once would be individually manufactured can be created via mass customization techniques, saving extensive amounts of time, wastage and cost. Products created in such a way will also be lighter but just as strong, if not stronger than being created by traditional methods.

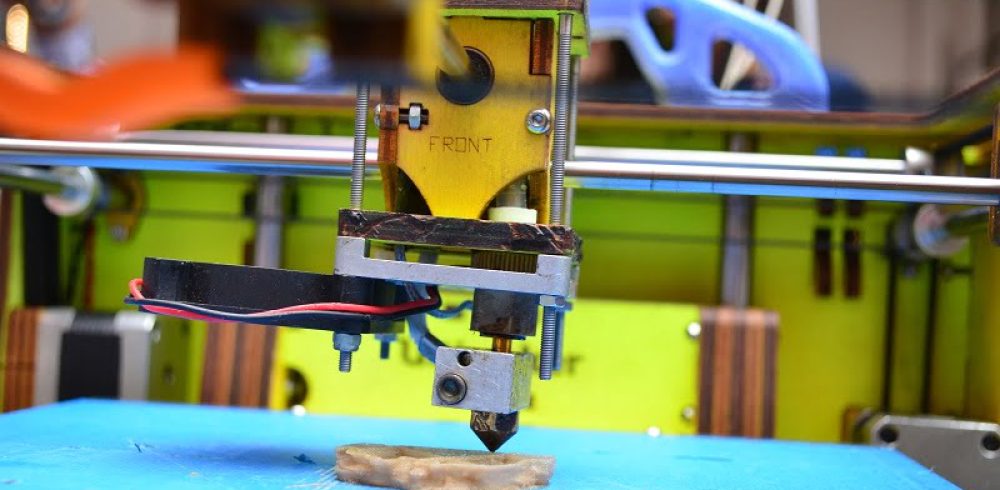

3D printing essentially offers an enormous leap between one of cases of the manufacturing process and large scale manufacturing. Combining 3D printing with efficient manufacturing will revolutionize in response to changing customer demands and the entire nature of manufacturing is set to take on a dramatic change as 3D printing becomes more integrated across global society. As traditional models become overlooked the philosophy of manufacturing is also changing, with products being made specifically to suit precise customer desire.

The implications for the logistics industry are believed to be massive! The extensive customisation of products would mean that inventory levels are set to fall as goods are made to order more frequently, reducing warehousing requirements. There is the potential a proportion of goods which have previously been produced in China or other Asian markets could be near-sourced to Europe and North Africa. Dramatically reducing shipping and air cargo volumes.

There are to be fewer opportunities for logistics suppliers to become involved with companies in upstream supply chains as companies become increasingly bound to their own single facilities. Downstream logistics are also set to be affected. The relatively new found built-to-order mass production process via 3D printing and advanced strategies could fundamentally impact the manufacture-wholesaler-retailer relationship. Expect for future shopping experience to also have vast differences. Some sectors of the retail world will either cease to exist or become mere windows for manufacturing promo, keeping little stock of their own in store but showing a firm display of what they can do for the client.

Orders are fulfilled via demand directly by the manufacturer and delivered to the home of the consumer for ultimate efficiency. A major new sector within the logistics industry is already emerging to deal with storage and movement of raw materials that aid to run and feed the 3D printers. As the software gradually becomes more affordable to the general public the at home delivery market for desired products increases.

The service aspect of the logistics sector has already been affected. Creating and dispatching products on such a small-time scale means machines are up and running almost at a constant. Service parts engineers are able to download designs or design parts from an online library, 3D print the model and then fit the product faster than ever before which is making the global and national need for part warehouses and stock locations unnecessary to fulfilling customer needs.

The fairly new technology is taking off step and by step and is integrating into modern manufacturing societies with open and excited arms. 3D printing is no longer science fiction, it is here, ready and able to aid manufacturers, engineers, architects and designers with essentially whatever they could ever need. In 2012 up to 30% of finished products were thought to involve some form of 3D printing, this went up to 50% in 2016 and is said to reach a potential of 80% by 2020.